Beneficiation method for extracting feldspar and quartz from granite

A granite and feldspar technology, applied in flotation, solid separation, etc., can solve the problem that granite is difficult to be effectively used, and achieve the effects of reducing depletion, reducing costs, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

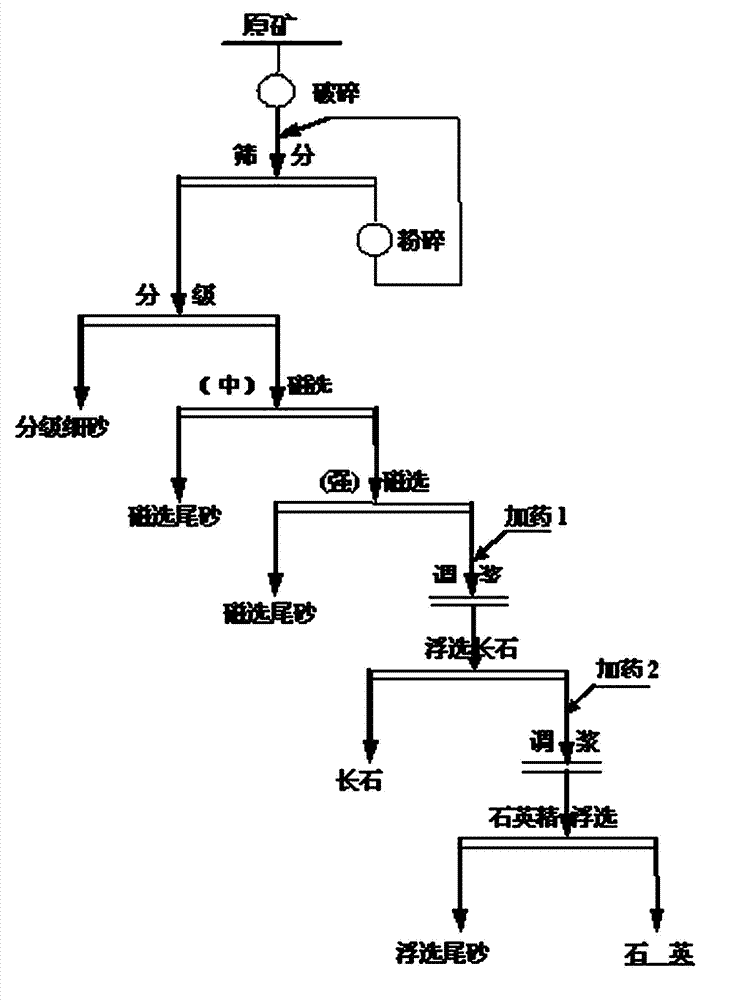

[0015] Implementation steps according to figure 1 The process shown is carried out under the following conditions:

[0016] Magnetic separation: medium magnetic field strength: 0.3T, high gradient magnetic separation field strength: 1.0T

[0017] Pretreatment: scrubbing concentration: 50%, scrubbing time: 15min

[0018] Scrub medium: H 2 SO 4 : 2.0kg / t, HF: 1.0kg / t

[0019] Flotation feldspar: ammonium salt collector: 4.0kg / t, PH: 2.5

[0020] Quartz fine flotation: amine salt and petroleum sulfonate mixed anion and cation collector: 4.1kg / t, PH: 2.5

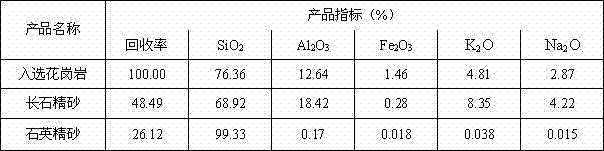

[0021] Example results Table 1

[0022]

[0023] The results show that the chemical indexes of the feldspar concentrate and quartz concentrate treated by the above process meet the requirements of the ceramic and glass industries, and have broad application prospects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com