Manufacturing process of furnace transmutation enamel

A manufacturing process and kiln-changing glaze technology, which is applied in the field of ceramic processing and manufacturing, can solve the problems of unusable, idle waste of high-iron titanium porcelain clay, etc., and achieve the effect of increasing coloring power, matching light and thick, and soft coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

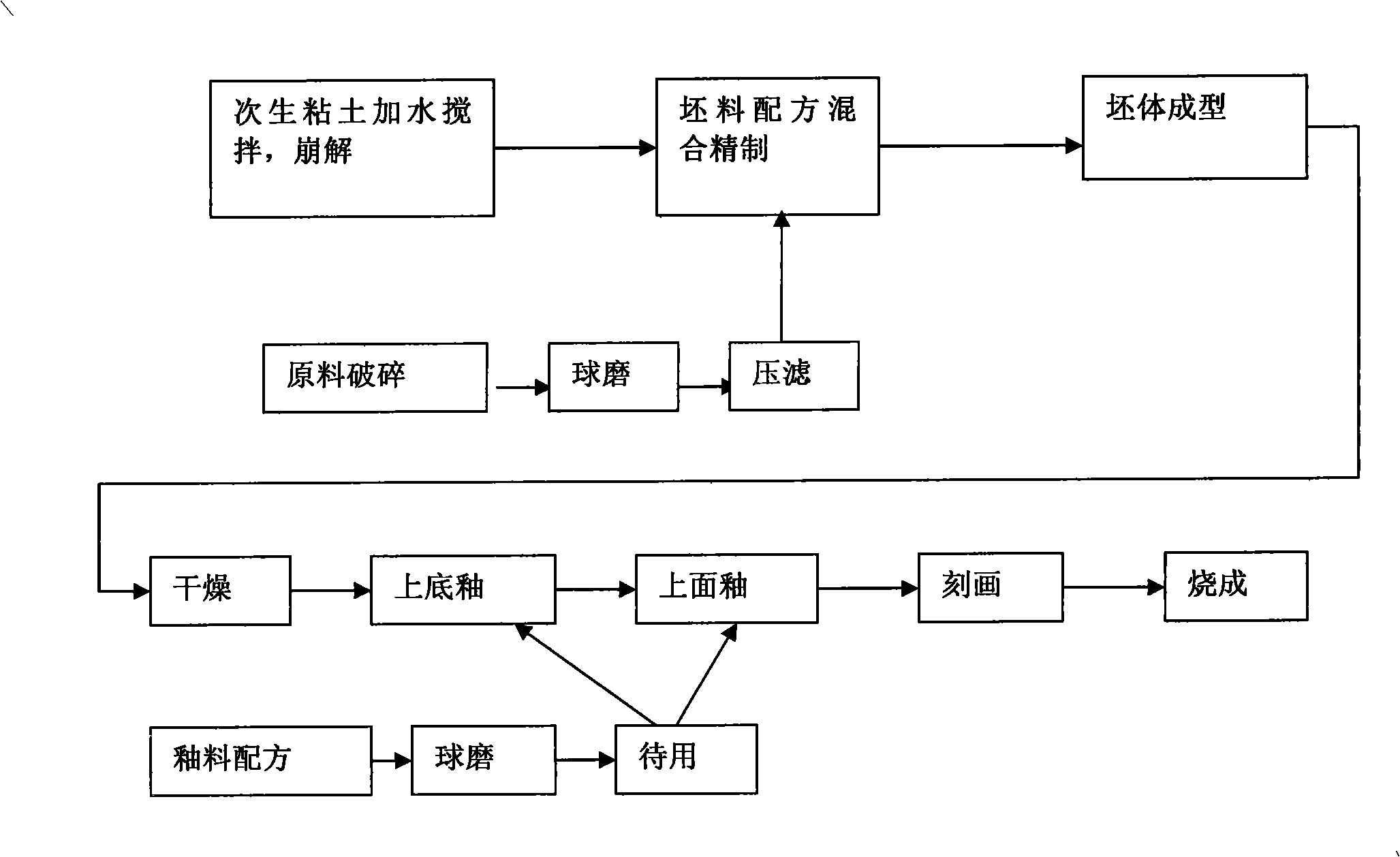

[0024] Accompanying drawing is the technological process schematic diagram of the present invention, as shown in the figure:

[0025] The manufacturing process of the kiln-change glazed porcelain of the present invention comprises the following steps:

[0026] a. Billet: select Fe 2 o 3 Content greater than 1%, TiO 2 For inferior china clay with a content greater than 0.2%, crush and grind the china clay, then ball mill and press filter (fineness requirement: 0.2% to 1.0% after sieve with 10,000 holes); add water to the secondary clay, stir evenly, and mix with The china clay after press filtration is mixed, adding part of iron-titanium oxide and rare earth metal elements accounting for less than 1.0% of the total mass, and pressing it into a green body under a certain pressure;

[0027] b. Bottom glaze making: ① Bottom glaze making: crush and grind the bottom glaze raw materials, add iron and titanium oxide and water ball mill, the fineness requirement of ball milling: 0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com