Device for preventing glaze slip from adhering to bottoms of ceramic tile blanks and control method of device

A glazing device and ceramic tile technology, which is applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of glaze waste, low strength of floor tiles, and mismatching speed of conveying devices, etc., and achieve unique design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

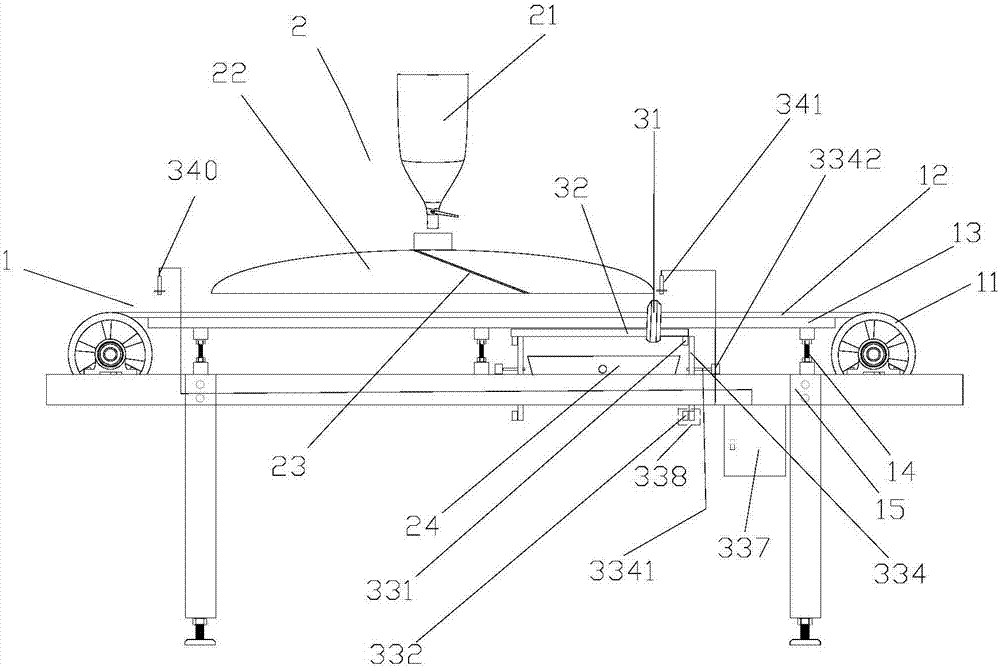

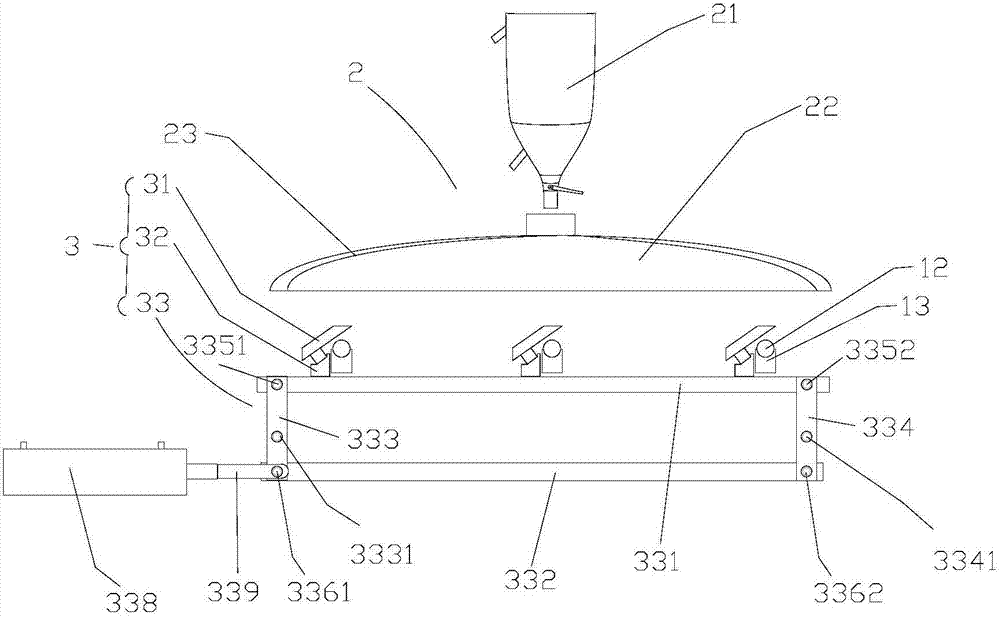

[0049] refer to figure 1 As shown, in order to achieve the above purpose, the device for preventing the glaze slurry from sticking to the bottom of the tile body according to the embodiment of the present invention adopts the following technical scheme: the device for preventing the glaze slurry from sticking to the bottom of the tile body includes a glaze line device 1, a glaze device 2 and a blocking A glaze device 3, the glaze line device 1 is located below the glaze device 2, and the glaze retaining device 3 is located below the glaze position of the glaze device 2;

[0050] The glaze line device 1 includes a pulley 11, a glaze line belt 12, a belt bracket 13, a support rod 14, and a glaze line bracket 15. The pulley 11 drives the glaze line belt 12 to run, and the glaze line belt 12 is embedded in In the belt bracket 13, the belt bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com