Low-light exquisite glaze, glaze slurry preparation method, glazed tile, and preparation method

A glazed tile, delicate technology, applied in the field of glazed tiles and its preparation, glaze slurry preparation, low-light fine glaze, can solve the problems that are not widely accepted by consumers, the crystallization is not fine enough, easy to produce capillary pores, etc., and achieve anti-fouling effect Good, the texture of the surface is delicate, solve the effect of low light and delicate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The method for preparing the glaze slurry of the above-mentioned low light fine glaze comprises the following steps:

[0040] Add 0.1-0.2% of sodium carboxymethyl cellulose, 0.3-0.6% of sodium tripolyphosphate, 60.2-70% of low-gloss and delicate glaze raw materials and 28-35% of water into a ball mill for wet ball milling, in which: Low-gloss fine glaze raw materials are added to the ball mill according to the ratio;

[0041] The slurry after ball milling is passed through a 140-180 mesh sieve;

[0042] Afterwards, the slurry is aged for 20 to 28 hours to obtain a glaze slurry of a low-gloss fine glaze.

[0043] Sodium carboxymethyl cellulose, sodium tripolyphosphate, water and low-gloss fine glaze raw materials are added to the ball mill for ball milling, which can improve the uniformity of the distribution of each raw material, and the slurry has a better homogenization effect. The slurry stale for a long time, which is beneficial to fully decompose the organic matt...

Embodiment 1

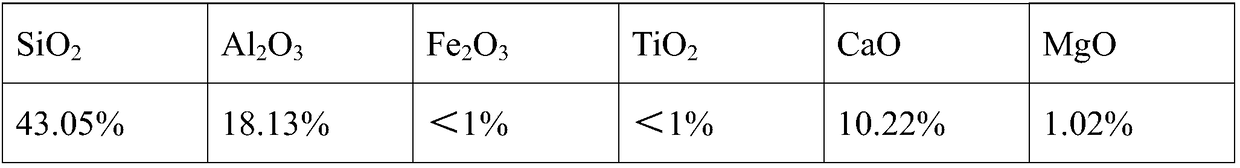

[0059] The chemical composition of the low-gloss delicate glaze of the present embodiment is shown in the table below:

[0060]

[0061]

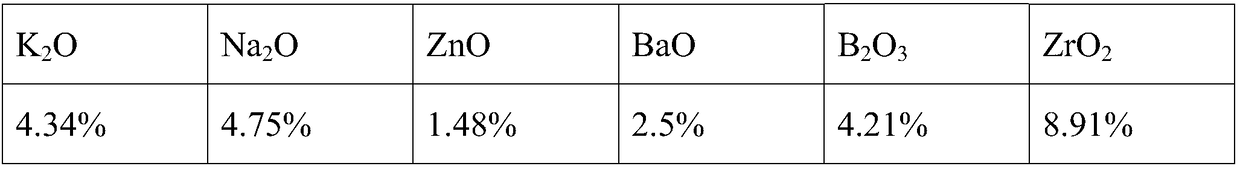

[0062] The raw material of the low-gloss delicate glaze of the present embodiment is shown in the table below in weight percentage:

High alumina clay

Aluminum oxide

burning talc

10%

8%

3%

20%

15%

3%

glass shards

3%

5%

2%

8%

15%

8%

[0064] The glazed tile containing the low-gloss fine glaze in this embodiment includes a low-gloss fine glaze layer and a base layer, and the low-gloss fine glaze layer is located on the top surface of the base layer.

[0065] The preparation method of the glazed tile containing the low-gloss fine glaze in this embodiment includes steps S1-S4:

[0066] S1. Prepare a glaze slurry for a low-gloss fin...

Embodiment 2

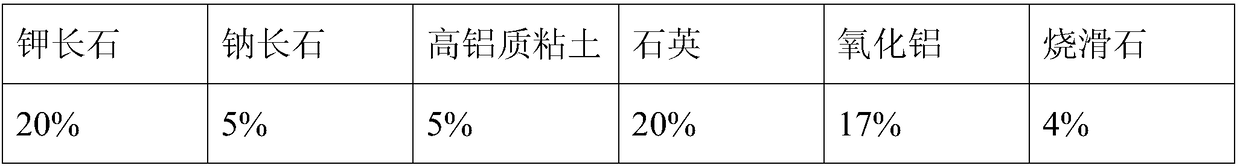

[0075] The chemical composition of the low-gloss delicate glaze of the present embodiment is shown in the table below:

[0076] SiO 2

al 2 o 3

Fe 2 o 3

TiO 2

CaO

MgO

37.23%

24.68%

<1%

<1%

15.63%

4.98%

K 2 o

Na 2 o

ZnO

BaO

B 2 o 3

ZrO 2

3.12%

4.91%

1.05%

1.01%

3.58%

3.05%

[0077] The raw material of the low-gloss delicate glaze of the present embodiment is shown in the table below in weight percentage:

High alumina clay

Aluminum oxide

burning talc

10%

5%

3%

21%

21%

8%

Zinc oxide

glass shards

3%

1%

1%

7%

5%

15%

[0079] The glazed tile containing the low-gloss fine glaze in this embodiment includes a low-gloss fine glaze layer and a base layer, and the low-gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com