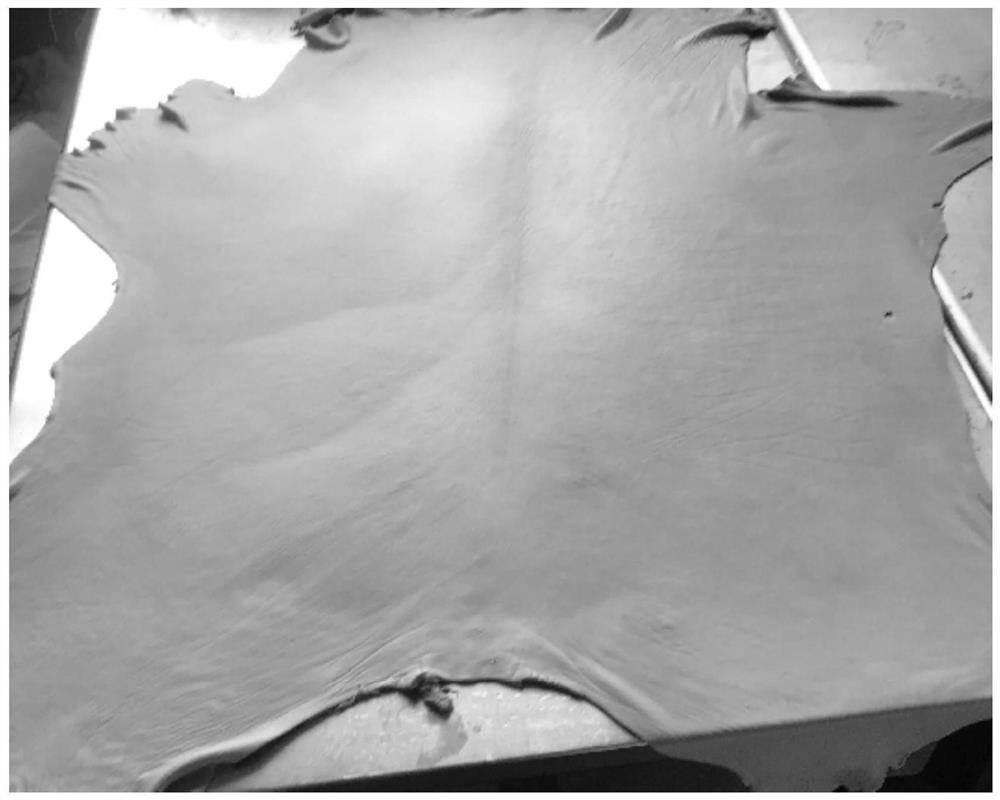

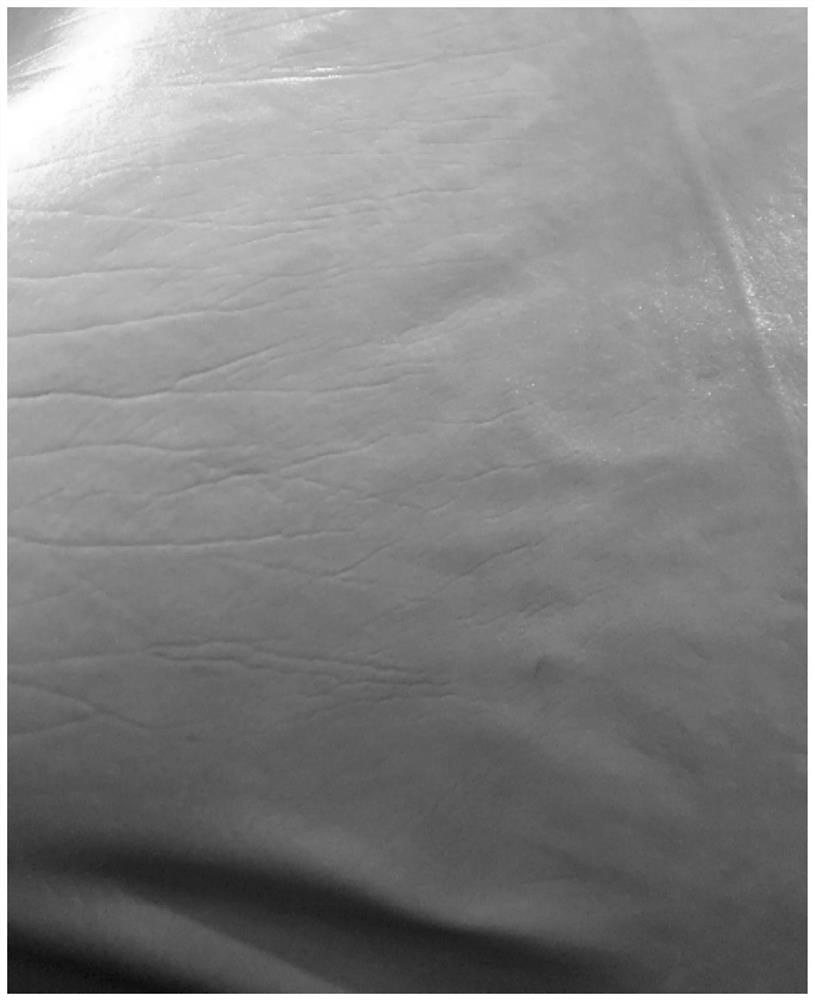

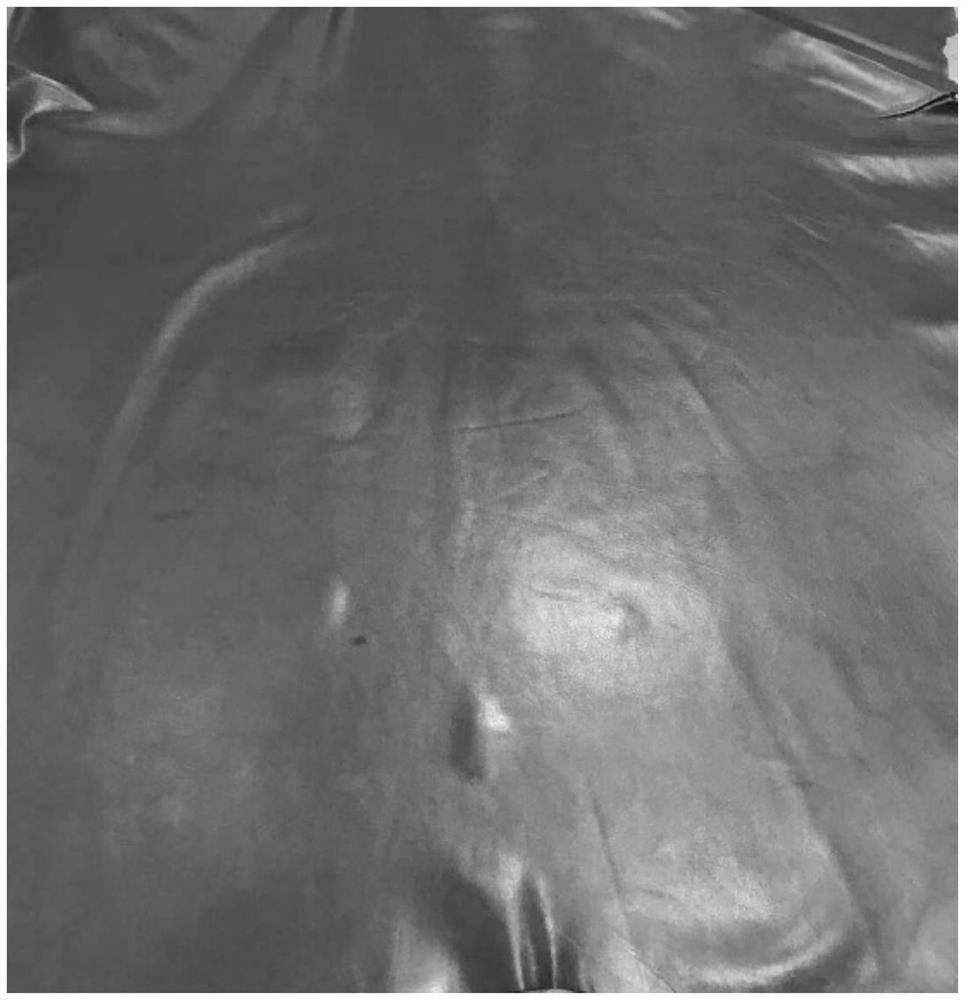

Fetal calf leather processing technology and fetal calf wet blue leather, fetal calf leather, fetal calf nubuck leather and its technology

A processing technology, technology of wet blue leather, applied in the processing technology of fetal calf leather, fetal calf nubuck leather and its technology, fetal calf wet blue leather and fetal calf leather, which can solve the problem of less fetal calf leather and relatively low processing research. Wait for the question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] One kind of wet blues fetal bovine process, which in turn comprises the following processing steps:

[0043] A1, raw hides fall salt: The raw hide into the cage in rotation, in turn a raw hide salts;

[0044] A2, flooding

[0045] Pre-soaking A2.1: Select six raw hides after the fall salts, the total weight of 21kg, into a rotating drum; 300% of added water to the drum 20 ℃, 0.2% Lanxess nonionic and anionic surfactants a mixture of an active agent SA-C, 0.2% anionic surfactant AN2-C, 0.2% Buckman Chemical (Shanghai) Ltd. bactericide 1078,0.5% soda ash, 0.2% skim LANXESS wetting agent AN2-C , turn 30min, stop 30min; then turn per hour 5min, continuous 20h, a drum, a fur to the meat;

[0046] A2.2 main flooding: 20 ℃ added 250% water, 0.5% of nonionic and anionic surfactant mixture SA-C, 0.4% TFL (Qingdao) Co., Ltd. In the soaking process can be effectively controlled pH the special additives 3154,0.1% skim wetting agent AN2-C, lipase FD 0.3% bactericide 1078,0.2% Shanghai H...

Embodiment 2

[0052] One kind of wet blues fetal bovine process, which in turn comprises the following processing steps:

[0053] A1, raw hides fall salt: The raw hide into the cage in rotation, in turn a raw hide salts;

[0054] A2, flooding

[0055] Pre-soaking A2.1: after six selected salts fall above skin material, the total weight of 21kg, into a rotating drum; 250% of added water to the drum 20 ℃, 0.3% added Lanxess nonionic and anionic surfactants a mixture of an active agent SA-C, an anionic surfactant, 0.4% Buckman Chemical (Shanghai) Ltd. bactericide 1078,0.5% soda ash, 0.3% skim LANXESS wetting agent AN2-C, 35min turn, stop 35min; hour then turn 8min, 21H continuously, the drum, for the fur to the meat;

[0056] A2.2 main flooding: 18 ℃ added 250% water, 0.4% of a nonionic and anionic surfactant mixture SA-C, 0.5% TFL (Qingdao) Co., Ltd. In the soaking process can be effectively controlled pH the special additives 3154,0.15% skim wetting agent AN2-C, 0.4% of bactericide 1078,0.3% Sha...

Embodiment 3

[0062] One kind of wet blues fetal bovine process, which in turn comprises the following processing steps:

[0063] A1, raw hides fall salt: The raw hide into the cage in rotation, in turn a raw hide salts;

[0064] A2, flooding

[0065] Pre-soaking A2.1: Select six raw hides after the fall salts, the total weight of 21kg, into a rotating drum; 280% of added water to the drum 22 ℃, Lanxess added 0.4% nonionic and anionic surfactants a mixture of an active agent SA-C, an anionic surfactant, 0.5% Buckman Chemical (Shanghai) Ltd. bactericide 1078,0.6% soda ash, 0.3% skim LANXESS wetting agent AN2-C, 35min turn, stop 35min; hour then turn 8min, continued 23 h, a drum, a fur fleshing; A2.2 main soaking: 18 ℃ added 200% water, 0.5% of nonionic and anionic surfactant mixture SA-C, 0.5% TFL (Qingdao) Co., Ltd. in the soaking process can effectively control the pH of special additives 3154,0.2% skim wetting agent AN2-C, 0.5% of bactericide 1078,0.5% Shanghai Hua Chen Industrial Co. company...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com