Graphene-containing lead alloy for lead storage battery grids, and preparation method thereof

A lead-acid battery and graphene technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems that lead alloy factories cannot achieve, the reduction reaction time is long, and it is difficult to popularize production, so as to enhance the performance of charge and discharge and cycle life, the effect of solving the decline in electrical conductivity and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

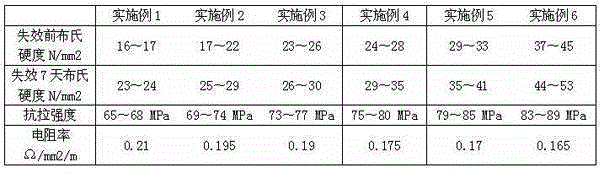

Examples

Embodiment 1

[0014] Example 1, a graphene-containing lead alloy for lead battery grids, comprising 0.015% graphene, 1.0% tin, 0.02% aluminum, 0.05% sponge calcium and 98.915% lead by weight . The preparation method comprises the following steps: (1) putting 2 / 3 of the amount of electrolytic lead into a lead melting pot, heating to 680°C until the electrolytic lead is completely melted; (2) then turning on the centrifugal mixer, and A certain amount of graphene is slowly and continuously added or added intermittently in batches into the lead liquid under the condition of stirring at a medium speed; (3) after 20 minutes, add the stated amount of pure tin bars and pure aluminum bars successively, and the centrifugal mixer continues Stir and mix for more than half an hour; (4) close the centrifugal mixer, add the amount of calcium sponge encapsulated with lead skin, press the calcium sponge encapsulated with lead skin into the bottom of the lead liquid with a bell jar with a leak at the bottom...

Embodiment 2

[0015] Example 2, a lead alloy containing graphene for lead storage battery grids, which contains 0.03% graphene, 1.2% tin, 0.04% aluminum, 0.08% sponge calcium and 98.65% lead. The preparation method comprises the following steps: (1) putting 2 / 3 of the amount of electrolytic lead into a lead melting pot, heating to 680°C until the electrolytic lead is completely melted; (2) then turning on the centrifugal mixer, and A certain amount of graphene is slowly and continuously added or added intermittently in batches into the lead liquid under the condition of stirring at a medium speed; (3) after 20 minutes, add the stated amount of pure tin bars and pure aluminum bars successively, and the centrifugal mixer continues Stir and mix for more than half an hour; (4) close the centrifugal mixer, add the amount of calcium sponge encapsulated with lead skin, press the calcium sponge encapsulated with lead skin into the bottom of the lead liquid with a bell jar with a leak at the bottom,...

Embodiment 3

[0016] Embodiment 3, a kind of lead-acid battery grid lead alloy containing graphene, calculated by weight percentage, it comprises 0.06% graphene, 1.2% tin, 0.04% aluminum, 0.1% sponge calcium and 98.6% lead. The preparation method comprises the following steps: (1) putting 2 / 3 of the amount of electrolytic lead into a lead melting pot, heating to 680°C until the electrolytic lead is completely melted; (2) then turning on the centrifugal mixer, and A certain amount of graphene is slowly and continuously added or added intermittently in batches into the lead liquid under the condition of stirring at a medium speed; (3) after 20 minutes, add the stated amount of pure tin bars and pure aluminum bars successively, and the centrifugal mixer continues Stir and mix for more than half an hour; (4) close the centrifugal mixer, add the amount of calcium sponge encapsulated with lead skin, press the calcium sponge encapsulated with lead skin into the bottom of the lead liquid with a bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com