Apparatus for annealing of crystal with high temp. resistance

An annealing device and high-temperature resistant technology, applied in the field of crystal annealing devices and annealing devices for high-temperature oxide crystals, can solve the problems of uneven induction heating temperature, small volume of crystal annealing chamber, poor crystal annealing effect, etc., and achieve optical uniformity. The effect of improving the property and crystal integrity, improving the optical quality of the crystal, and stabilizing the temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

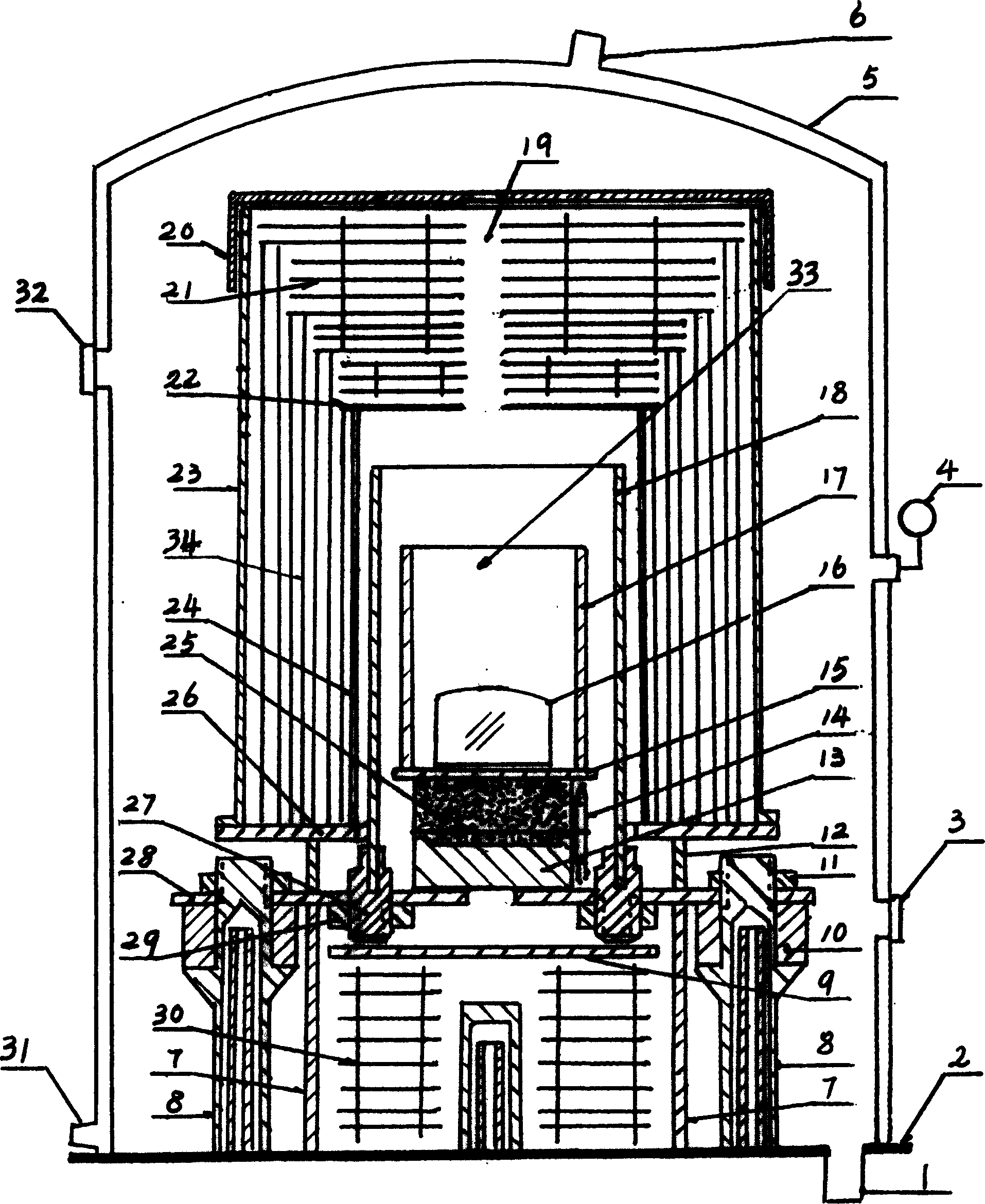

[0010] like figure 1 A high-temperature-resistant crystal annealing device is shown, which includes being placed on a chassis 2 with a vacuum exhaust port 1, and is provided with a water inlet 31, a water outlet 6 and a vacuum pressure in sealing contact with the chassis 2 through a vacuum sealing ring. The bell jar 5 of Table 4 is provided with a thermal insulation shielding device including a side shielding cylinder 34, an upper thermal baffle 21 and a lower thermal baffle 30 in the bell jar 5. Its main feature is: There is an inflation valve 3 and an air outlet valve 32; the heating element 18 arranged on both sides of the innermost shielding cylinder 24 is made of tungsten rod, and the heating element 18 is fastened to the molybdenum nut 29 through the molybdenum electrode joint 27. Two molybdenum electrode plates 28; the two molybdenum ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com