High temperature heating vacuum evaporation film coating device

A technology of vacuum evaporation and high temperature heating, applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problems of easy mutual pollution of evaporation materials, single evaporation chamber, affecting the purity of evaporated products, etc. Adhesion, simplified operating procedures, effect of increased temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

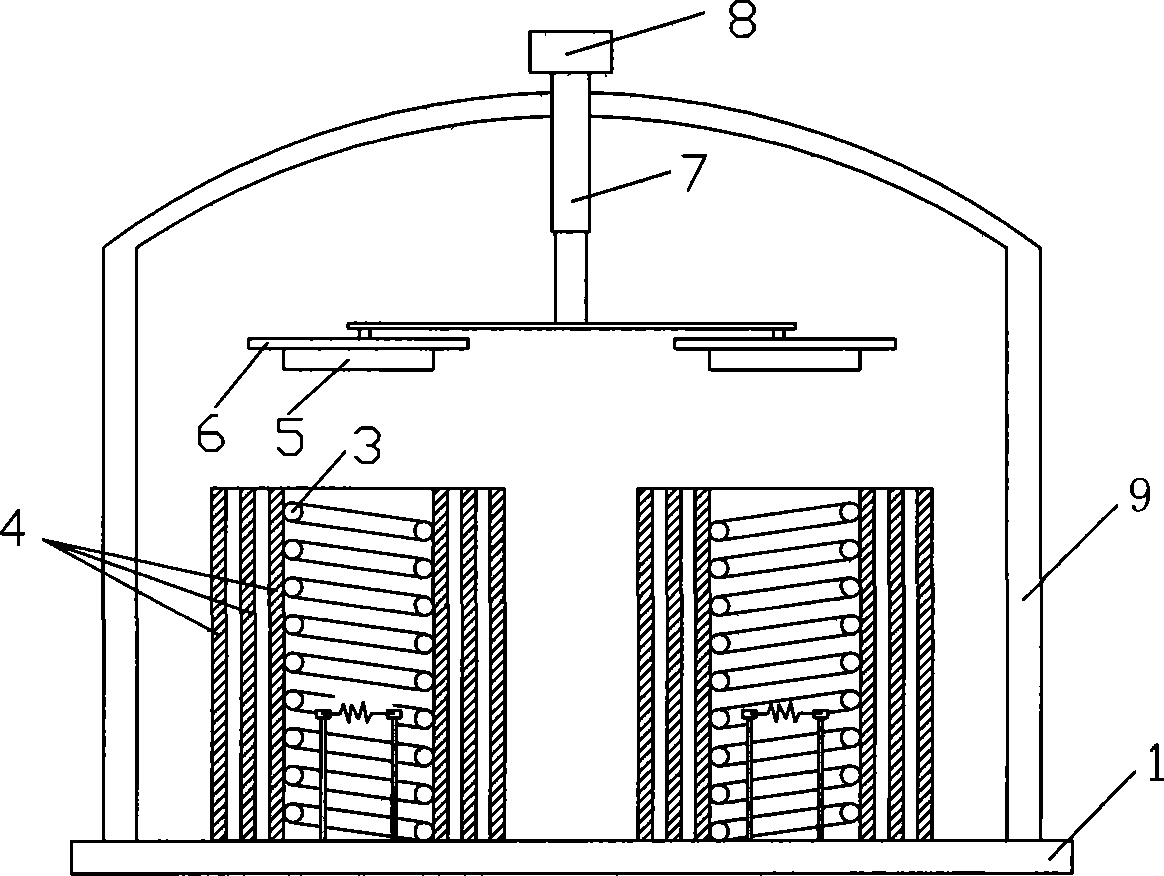

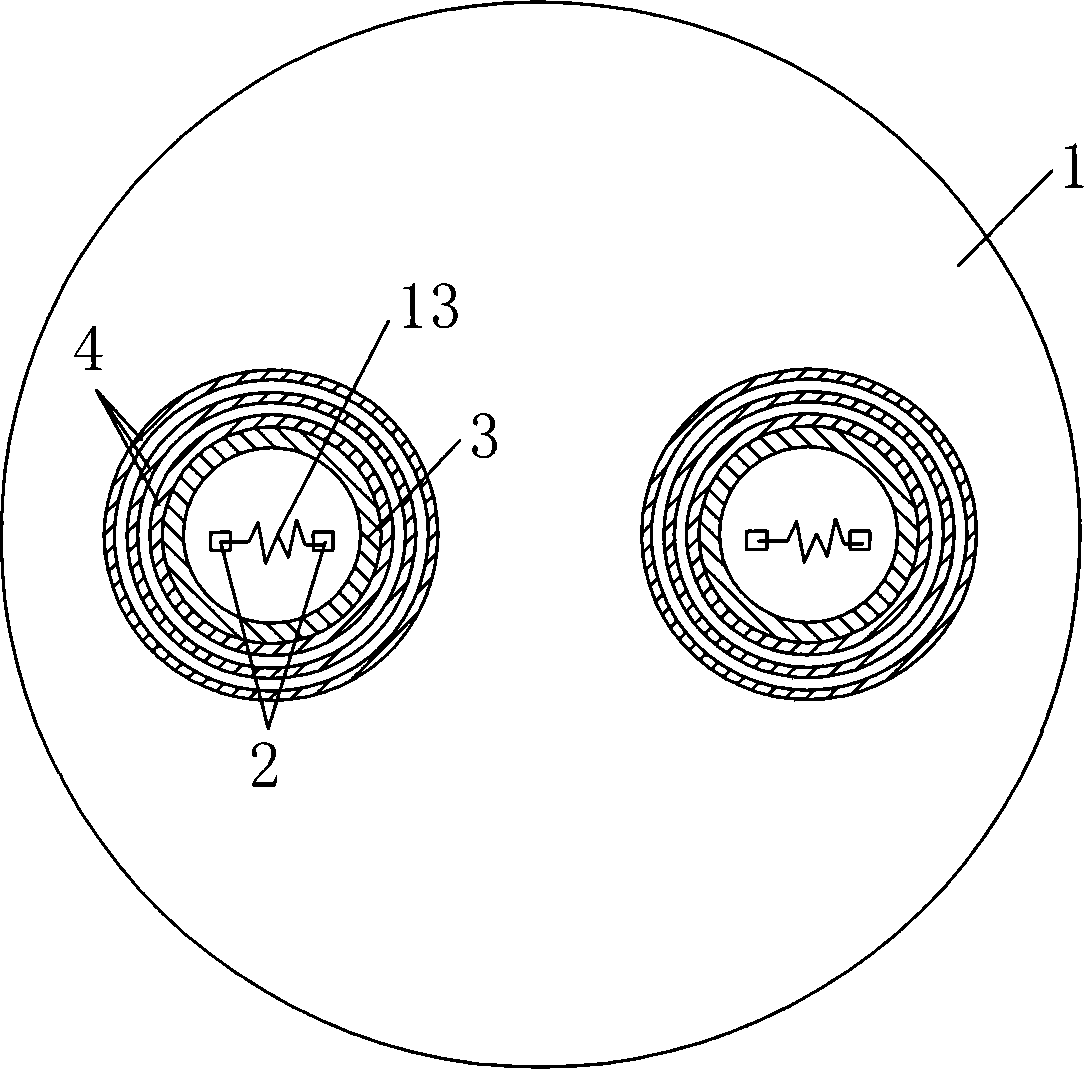

Method used

Image

Examples

Embodiment 2

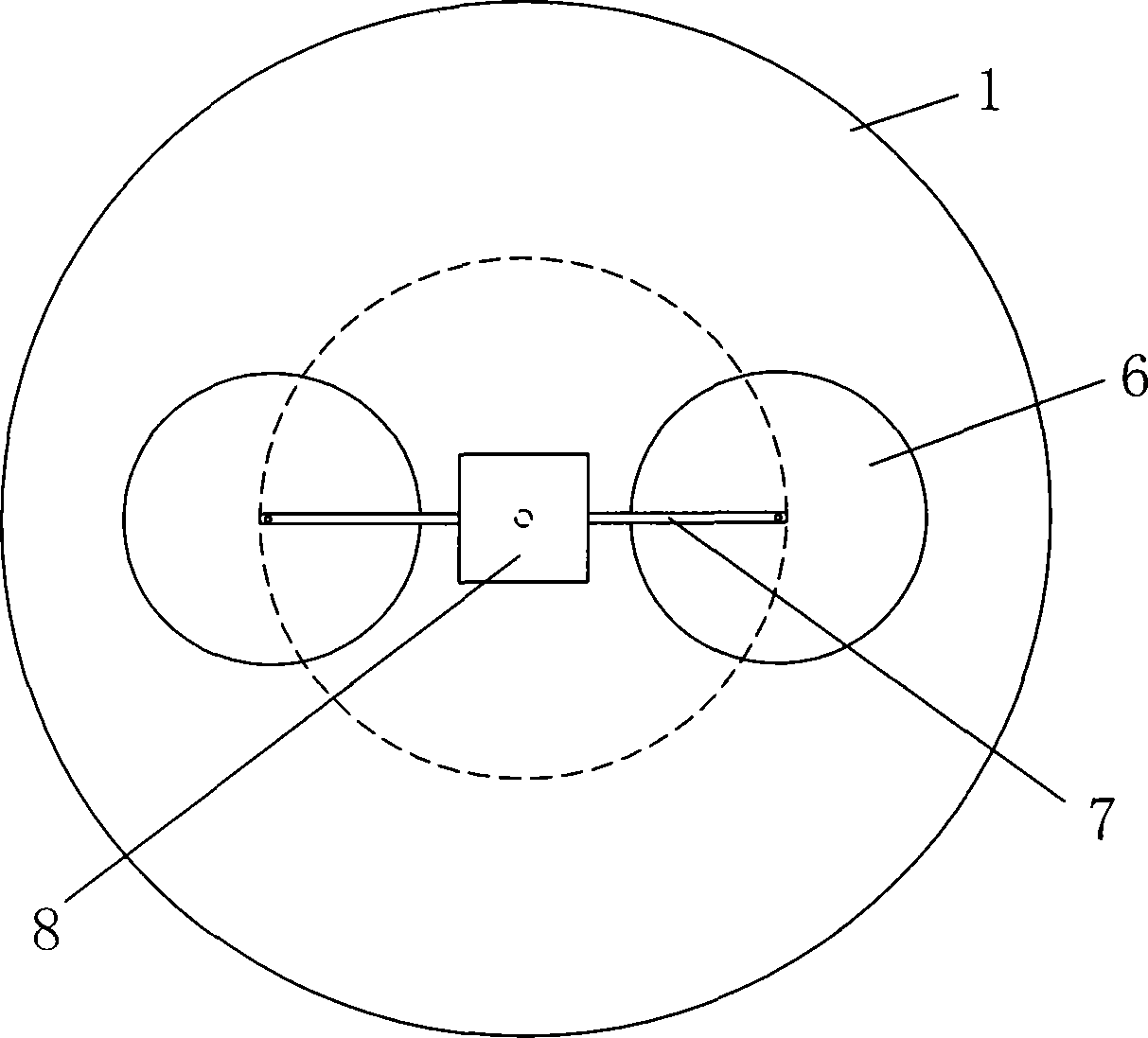

[0019] Example 2, such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the substrate holder base 6 is connected to the bell jar 10 through the manipulator 7, where the manipulator 7 is an inactive device, and is only used to fix the substrate holder. Base 6. A base 14 is provided below the base 1, a driving device is provided between the base 1 and the base 14, and a lifting and rotating device 12 is arranged in the driving device, which is used to control the base 1 and set on the base. The evaporation chamber on 1 rises and rotates, so that the evaporation chamber is in a closed state during the heating and evaporation process. The lifting and rotating devices described in this embodiment are both implemented in the prior art, so the internal structure thereof will not be described in detail here.

[0020] In order to be able to control the temperature in the evaporation chamber in real time, the present invention is also provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com