High-blast-temperature hot-blast stove burnt in convection swirling heat storage medium

A heat storage medium and hot blast stove technology, applied in brick blast furnaces, etc., can solve problems such as waste of energy, complex structure, insufficient combustion, etc., and achieve the effect of increasing the temperature of hot blast, improving heat transfer effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

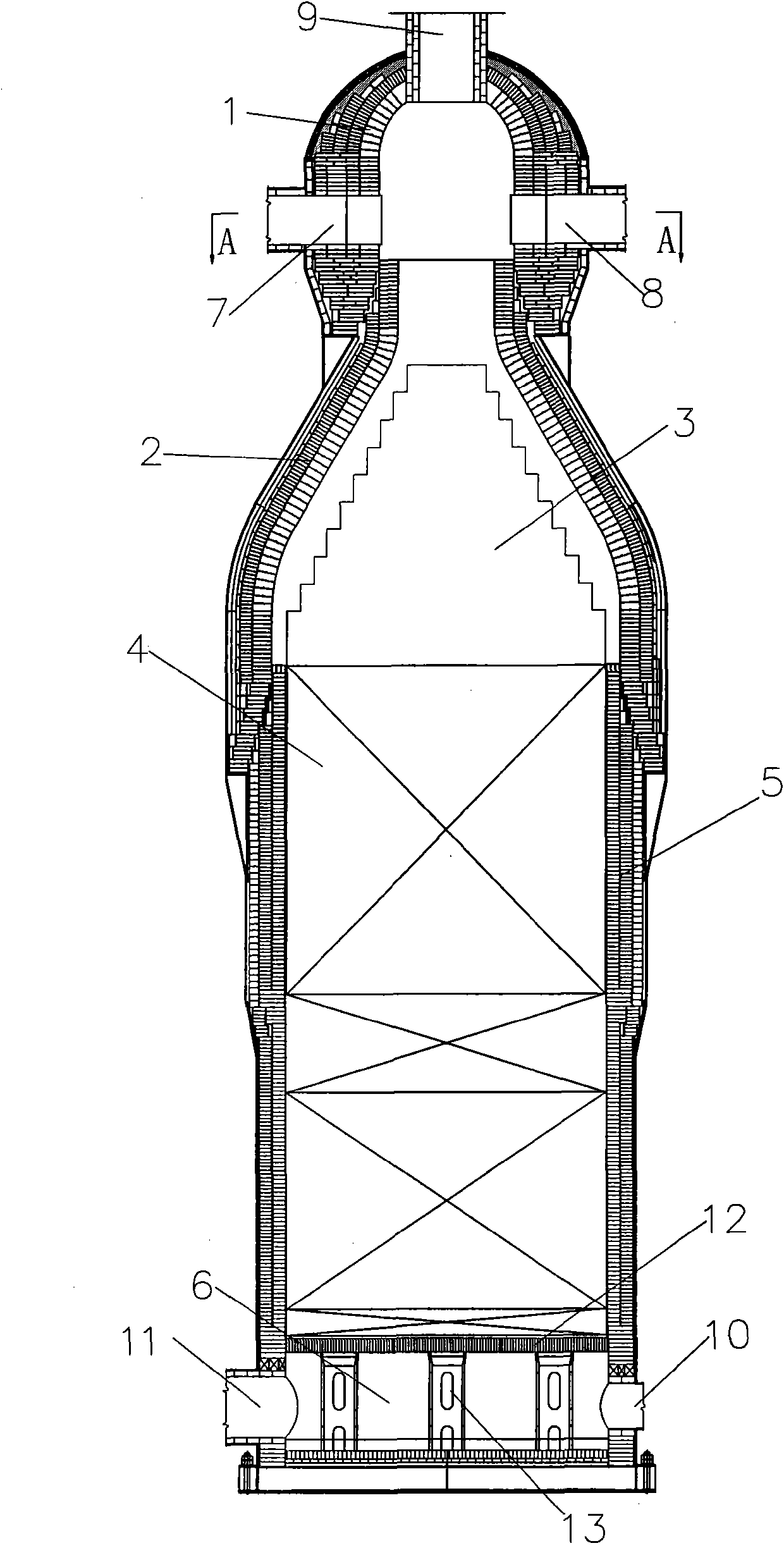

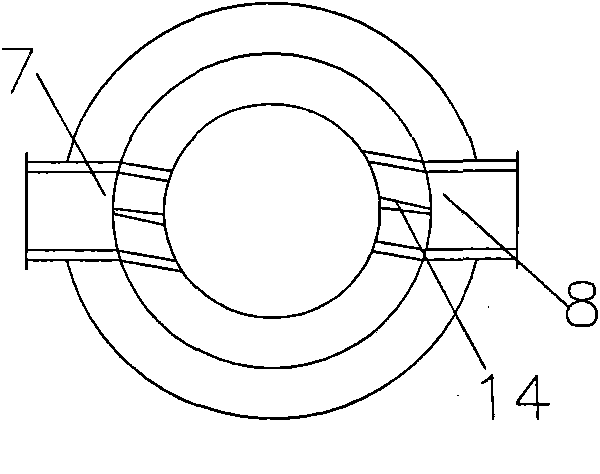

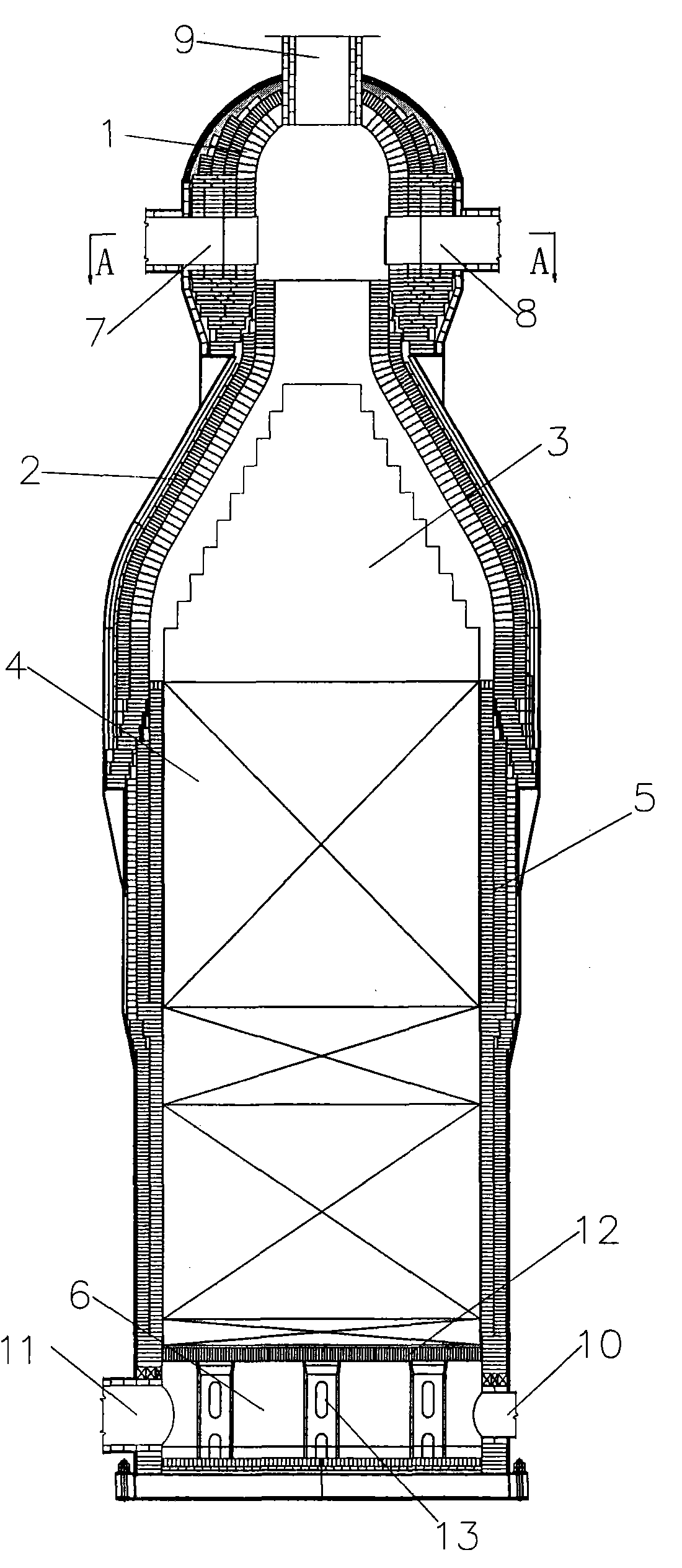

[0009] Depend on figure 1 , 2 Shown, the present invention is, in the steel casing, is formed by masonry by the refractory material of different specification, and it is formed by pre-combustion chamber (1), the porous regenerator ( 3), the regenerator (5) and the regenerator (4) stacked with checker bricks in it, and the cold air chamber (6) together constitute the overall structure of the hot blast stove. The pre-combustion chamber (1) and its The lower conical combustors (2) are connected by a labyrinth without stress, and the conical combustors (2) are fully filled with porous regenerators (3), which together form a gas flow that can rotate and mix in it. , the combustion device of combustion, on the vertical wall body of pre-combustion chamber (1), the gas intake pipe (7) and the air intake pipe (8) of vertical hot blast ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com