Energy-saving polysilicon reduction furnace and manufacturing method for polysilicon

A manufacturing method and reduction furnace technology, applied in chemical instruments and methods, sustainable manufacturing/processing, silicon compounds, etc., can solve problems such as energy dissipation, achieve the effect of improving conversion rate and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

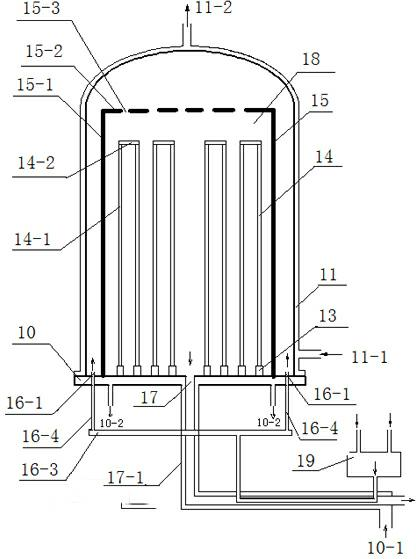

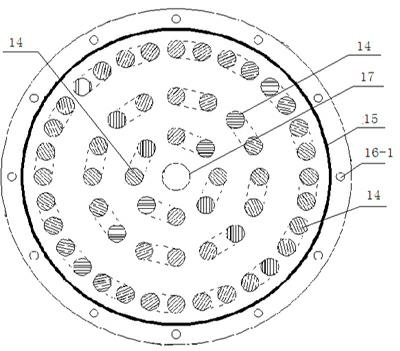

[0042] use as figure 1 and image 3 In the reduction furnace with the structure shown, after installing 28 groups of silicon core rods, the heat shield 15 and the bell-type furnace wall 11 are successively placed on the chassis 10; after the reduction furnace chamber is replaced with nitrogen, the reduction is replaced with hydrogen In the furnace chamber, use 8~12KV voltage to activate the silicon core rod to conduct electric heating, heat the silicon core rod to 1100℃~1200℃, and then feed the raw gas into the gas mixing chamber. Such as figure 1 As shown, the raw gas enters the gas mixing chamber 19, the mixed gas is preheated by the tail gas coming out of the exhaust port 17, and then the mixed gas is drawn out from the pipeline 17-1 through a pipeline and then used an annular coil 16-3 Separate the mixed gas from such as figure 1 Riser 16-4 shown, from as image 3 The 16 evenly distributed raw material gas inlets 16-1 are fed into between the bell-type heat shield and ...

Embodiment 2

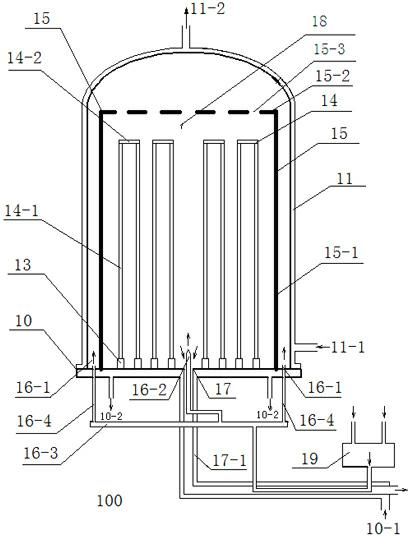

[0044] use as figure 2 and Figure 4 In the reduction furnace shown in the structure, two long silicon core rods 14-1 and one short silicon core rod 14-2 are formed into a group, one end of the long silicon core rod is sharpened as the upper end, and the two ends of the short silicon core rod are cut The hole is matched with it, the tip is inserted into the hole as a group, and a total of 28 groups of silicon core rods 14 are erected on the electrode chuck 13; the heat shield 15 and the bell-type furnace wall 11 are successively placed on the chassis 10; After replacing the chamber of the reduction furnace with nitrogen, replace the chamber of the reduction furnace with hydrogen, preheat the silicon core rod 14 with a graphite heater or a refractory metal heater to become a conductor, and heat the silicon core rod 14 to 1100°C~1200°C ℃; figure 2 As shown, the raw gas enters the gas mixing chamber 19, and the mixed gas is preheated by the exhaust gas coming out from the exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com