Experimental facility for measurement of hot forming limit of laser tailor-welded blank

An experimental device, laser tailor welding technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve problems such as experimental difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

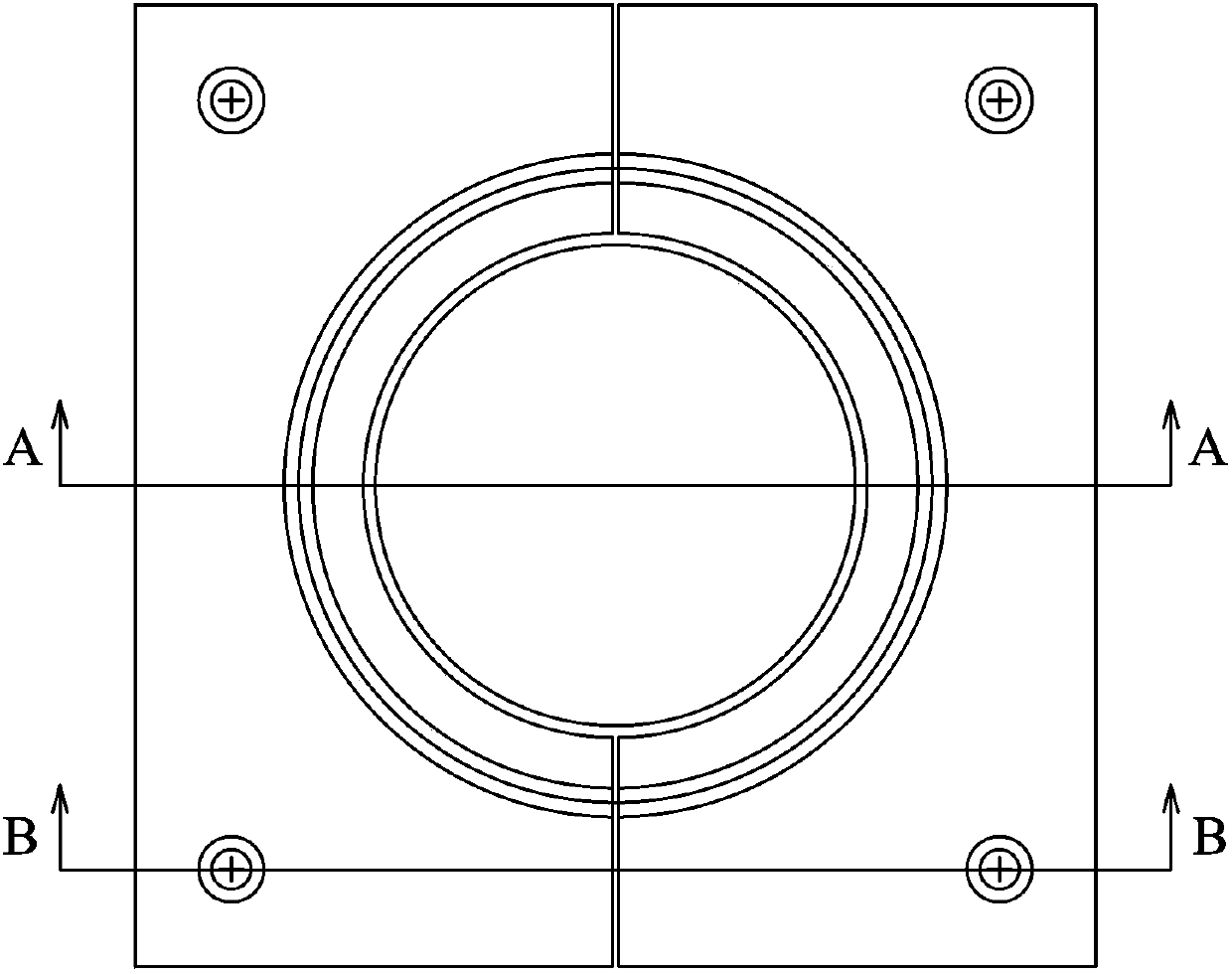

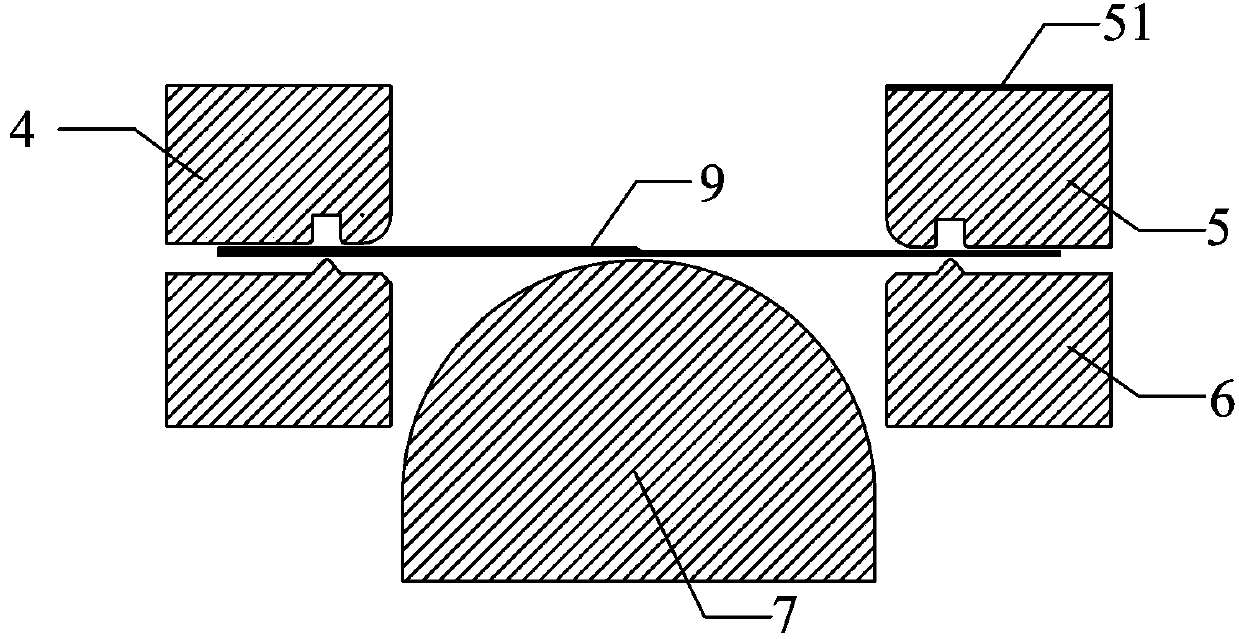

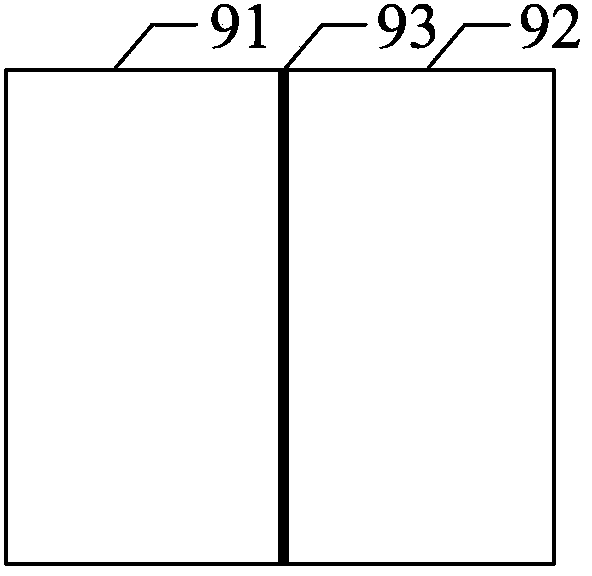

[0022] Such as Figure 6 As shown, an experimental device for measuring the high-temperature forming limit of tailor-welded blanks, the experimental device includes an upper mold base 1 and a lower mold base 2, and the upper mold base 1 and the lower mold base 2 are formed for An accommodating space for the main body of the experimental device, the main body of the experimental device includes a heating temperature control bell jar 3 placed on the support platform of the lower mold frame 2 and a spherical punch 7 placed in the heating temperature control bell jar 3 , Punch blank holder 6, Die blank holder (such as figure 1 , figure 2 shown). In this embodiment, the tailor welded blank 9 (such as image 3 , Figure 4 As shown) the differential thickness sheet composed of sheet I91, sheet II92 and tailor welding connection part 93, the corresponding die blankholder is composed of two parts, namely the main blankholder 4 and the adjustable differential thickness blankholder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com