A ceramic/ceramic connection method for intermediary solder layer controlled by multi-physics coupling

A multi-physics and connection method technology, applied in the field of material connection, can solve the problems of cracks, pores, insufficient mechanical properties of welded joints, and large glass brittleness in welds, so as to eliminate weld defects, reduce residual thermal stress, The effect of improving the toughness of the weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

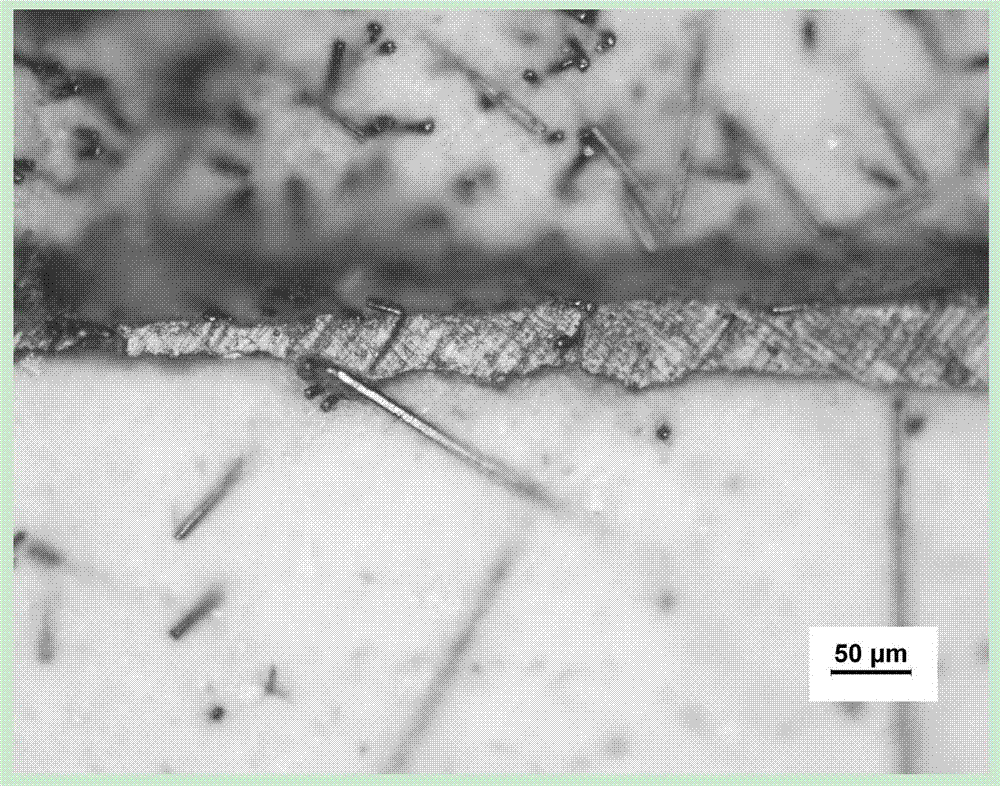

[0022] A ceramic / ceramic connection method for multi-physics field coupling and regulation of the intermediate solder layer, using a heat source to melt the solder or solder and part of the base material, while additionally applying a physical field, the steps are as follows:

[0023] 1) Cleaning of ceramic surface to be welded

[0024] Remove grease and stains from the surfaces of alumina ceramic sheets and silicon carbide ceramic sheets to be welded, pre-treat them with mechanical grinding, remove the oxide film initially, and then clean them with an ultrasonic cleaner;

[0025] 2) Preparation of solder

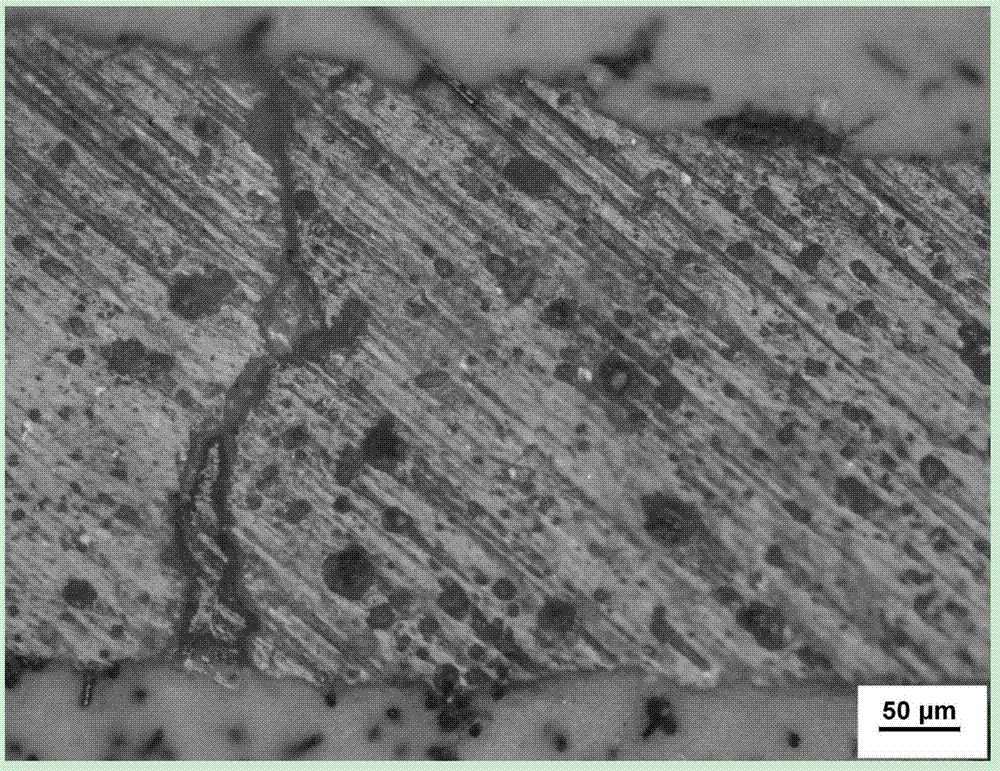

[0026] The solder is a mixed material of glass powder and silicon carbide whiskers, wherein the volume percentage of silicon carbide whiskers is 30%, and the mixed material of glass powder and silicon carbide whiskers is put into a ball mill and mixed evenly to make powdery solder;

[0027] 3) ceramic / ceramic connection

[0028] Place the composite solder prepared above b...

Embodiment 2

[0032] A ceramic / ceramic connection method for multi-physics field coupling and regulation of the intermediate solder layer, using a heat source to melt the solder or solder and part of the base material, while additionally applying a physical field, the steps are basically the same as in Example 1, the difference is: The base materials are alumina ceramic sheets and silicon nitride ceramic sheets.

[0033] The histograms without ultrasonic application and with ultrasonic application are similar to Example 1.

Embodiment 3

[0035] A ceramic / ceramic connection method for multi-physics field coupling and regulation of the intermediate solder layer, using a heat source to melt the solder or solder and part of the base material, while additionally applying a physical field, the steps are basically the same as in Example 1, the difference is: in the aluminum oxide In the mixed material solder used between the ceramic sheet and the silicon carbide ceramic sheet, the reinforcing phase silicon carbide is in the form of particles.

[0036] The histograms without ultrasonic application and with ultrasonic application are similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com