Stirring knife for sewage treatment, using method and equipment

A kind of sewage treatment equipment and sewage treatment technology, applied in the direction of water/sewage treatment, water/sludge/sewage treatment, mixer accessories, etc., can solve the problems that are not clearly disclosed, do not focus on the development of mixing equipment, etc., to fill the gap, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

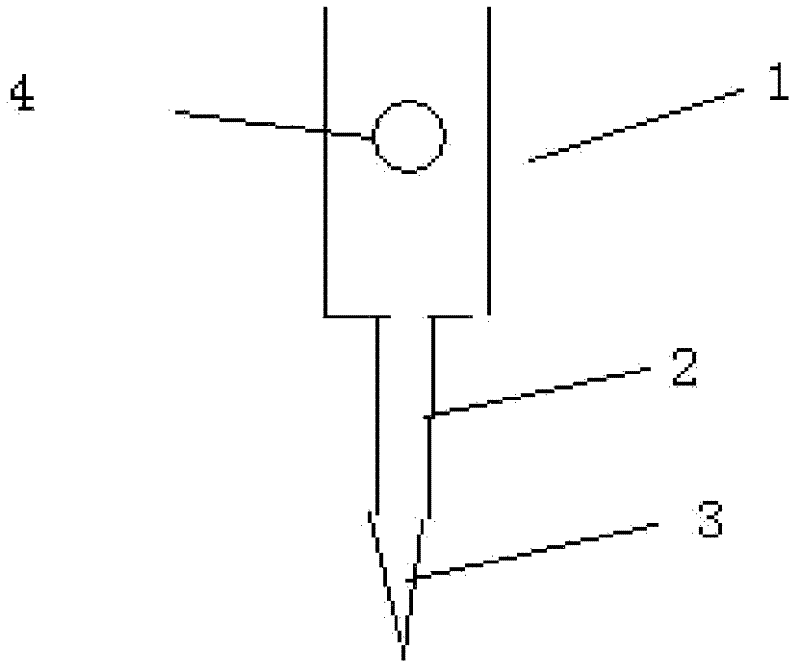

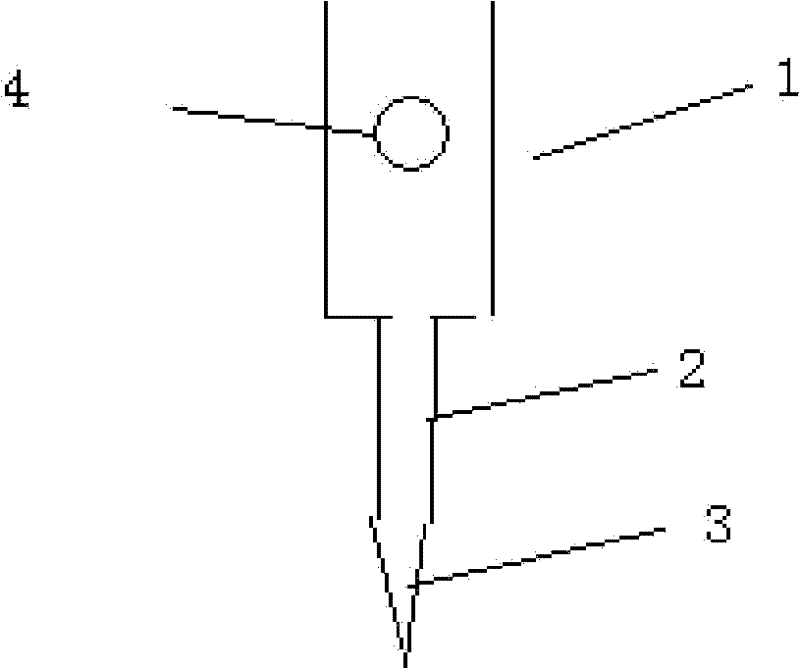

[0017] A mixing knife for sewage treatment, including a handle and a blade, the handle is composed of two sections, the first section is flat, the second section is cylindrical, the flat part is connected with the cylindrical part, and the cylindrical handle is The powder is connected to the blade part, the cylindrical handle part is telescopically adjustable, and the flat part contains a bolt hole for fixed connection; the mixing knife matrix is composed of an alloy with the following components: C is 0.2%, Ni is 22.2%, Cr is 0.45%, V is 0.65%, Nb is 0.145%, Mo is 12.6%, Zr is 3.85%, and the balance is iron and unavoidable impurities; a layer of aluminum layer is deposited on the mixing knife, its The thickness is 1.2mm, and then two-stage nitriding is carried out on the aluminum layer under vacuum conditions to form a gradient aluminum nitride layer; the first-stage nitriding time is 30 minutes, the second interval is 15 minutes, and the first-stage nitriding temperature is...

Embodiment 2

[0019] A mixing knife for sewage treatment, including a handle and a blade, the handle is composed of two sections, the first section is flat, the second section is cylindrical, the flat part is connected with the cylindrical part, and the cylindrical handle is The powder is connected with the blade part, the cylindrical handle part is telescopically adjustable, and the flat part contains a bolt hole for fixed connection; the base of the stirring knife is composed of an alloy with the following components:

[0020] C is 0.15%, Ni is 21%, Cr is 0.3%, V is 0.55%, Nb is 0.143%, Mo is 12.5%, Zr is 3.5%, and the balance is iron and unavoidable impurities.

[0021] Deposit a layer of aluminum on the mixing knife with a thickness of 0.5-1.2mm, and then carry out two-stage nitriding on the aluminum layer under vacuum conditions to form a gradient aluminum nitride layer; the first stage nitriding time is 35min, the second The interval is 20 minutes, the nitriding temperature in the fir...

Embodiment 3

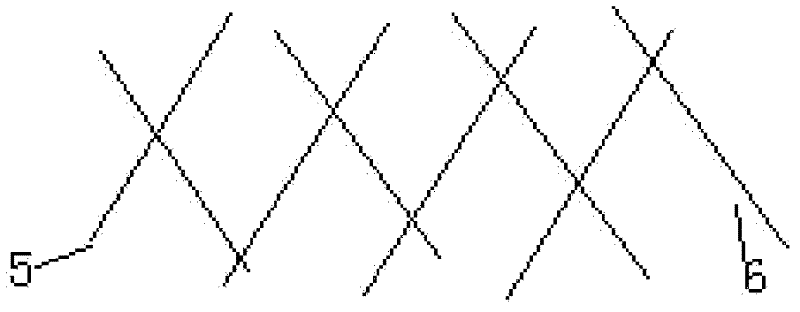

[0023] The method of using the above-mentioned mixing knife is to fix the mixing knife to the sewage treatment equipment through the bolt hole, so that the mixing knife is placed side by side in the sewage at an inclination of 60°, the blade part is submerged in the sewage, and the cylindrical knife handle is at least partly leaked , the flat handle must not be submerged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com