Weeding machine

A weeding machine and weeding technology, applied in the field of weeding machines, can solve problems such as inconvenient mowing operation, and achieve the effect of convenient weeding work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

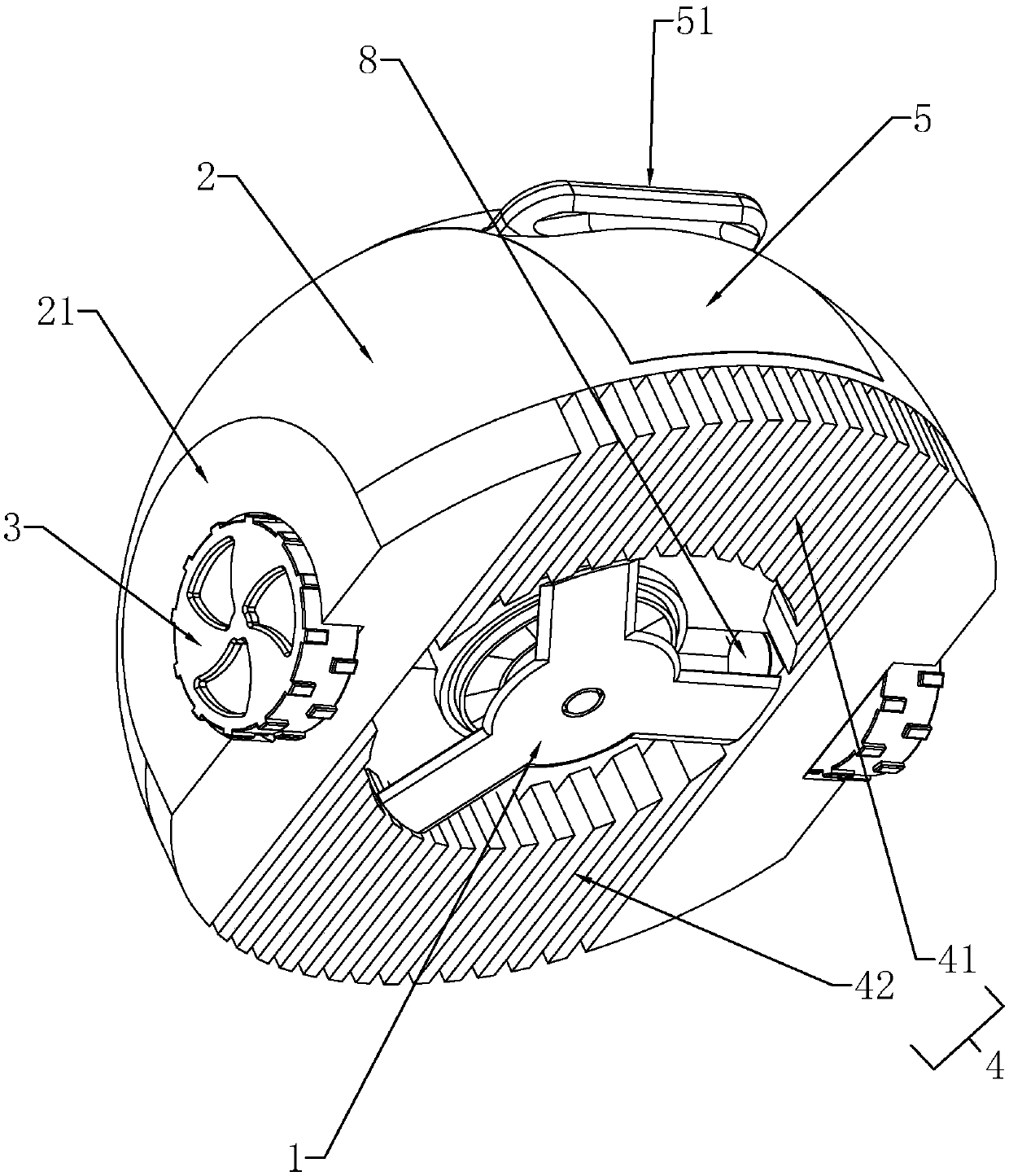

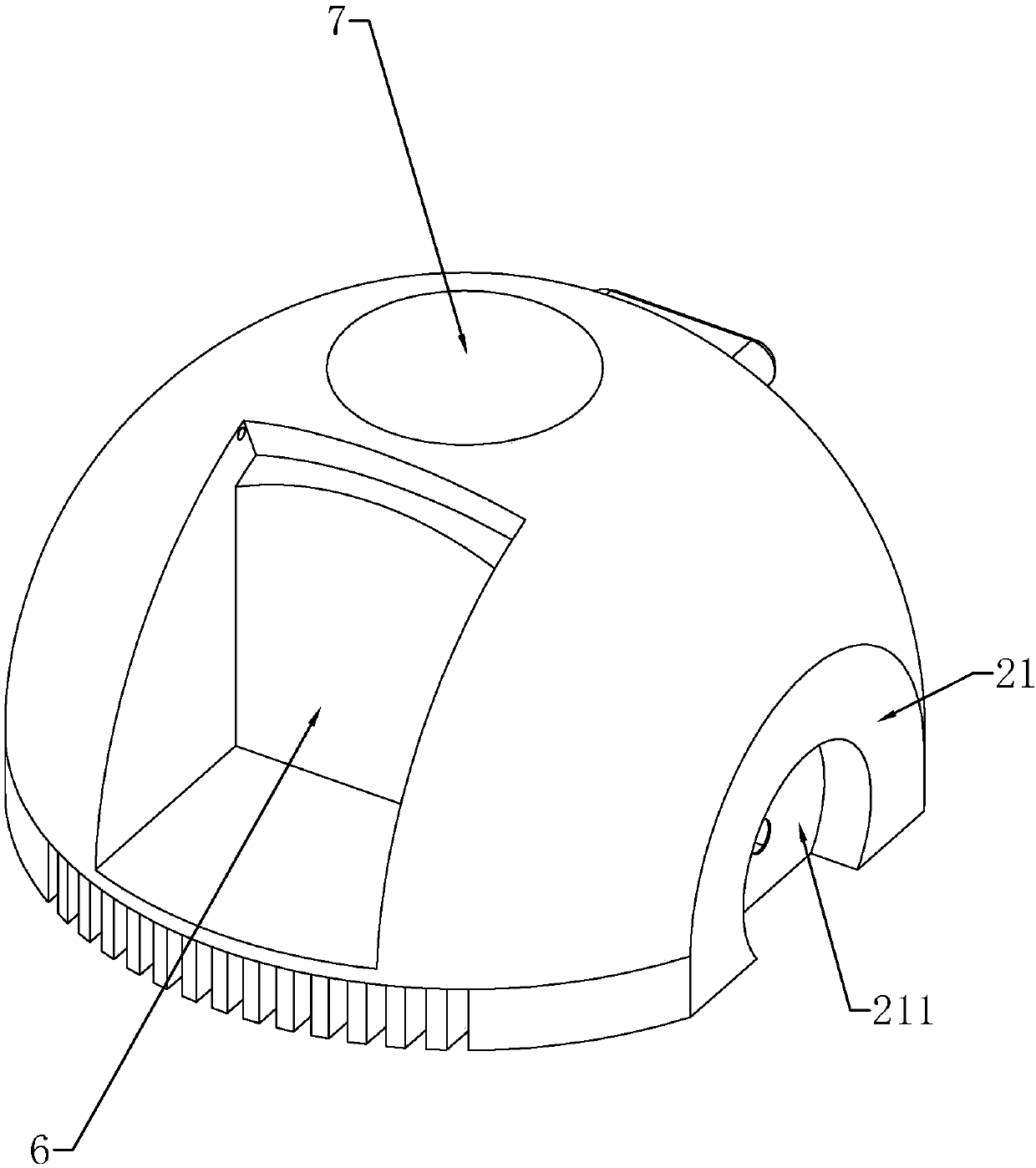

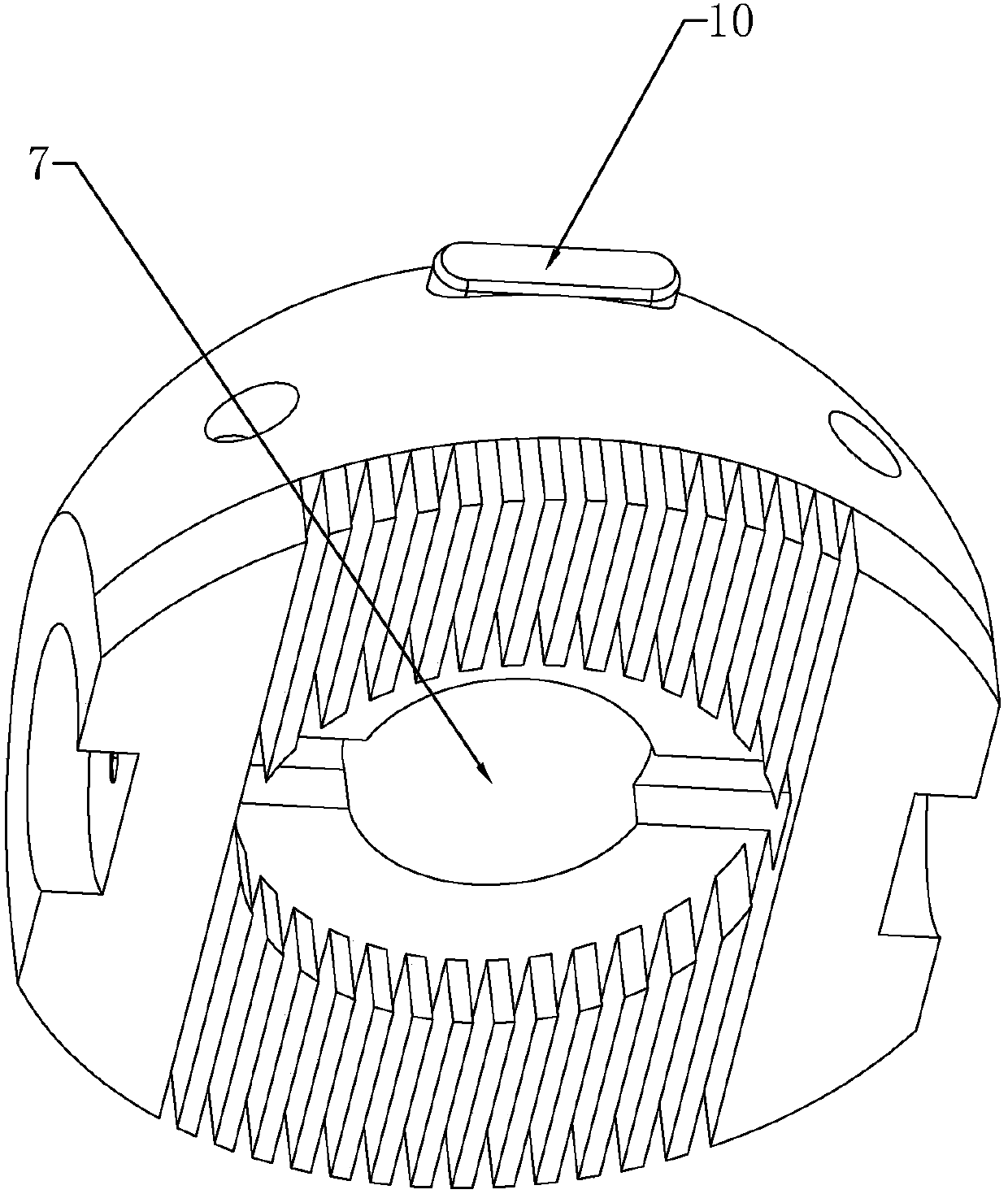

[0018] pass Figure 1 to Figure 4 The weeder of the present invention is further described.

[0019] A weeding machine, comprising a housing 2, a power supply, a weeding mechanism and a driving mechanism, the power supply is a storage battery, the power supply is electrically connected to the weeding mechanism and the driving mechanism, and supplies power to the weeding mechanism and the driving mechanism; the casing 2 The profile is hemispherical, and it has weeding motor chamber 7, and described weeding motor chamber 7 is cylindrical and coaxial with the radius of housing 2, and is perpendicular to the bottom surface of housing 2; Mounting surface 21, mounting surface 21 intersects with the bottom surface of housing 2, two mounting surfaces 21 are arranged symmetrically with the center of housing 2, and roller installation groove 211 is arranged on mounting surface 21; Described weeding mechanism comprises weeding motor and blade 1 , the weeding motor is installed in an inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com