Method for peeling fresh kernel corn and machine for peeling quick freezing fresh kernel corn

A technology of fresh corn kernels and peeling machine, which is applied in the fields of peeling vegetables or fruits, preserving seeds by freezing/cooling, food science, etc., can solve the problems of inability to peel fresh corn kernels, and achieve good peeling quality and smooth taste. , good peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0008] Specific embodiment 1: The peeling method of fresh corn kernels described in this embodiment is realized according to the following steps: 1. Material selection and finishing treatment: select fresh corn cobs, wash and dry the water, and put them in an environment of 100°C to 120°C Steam for 10 to 30 minutes to finish, and cool the corn cobs after the treatment with cold water for 8 to 10 minutes, so that the core temperature of the corn cobs will drop below 25°C and dry the surface moisture with wind; 2. The corn cobs that have completed step 1 Use a fresh corn thresher for threshing, and then refrigerate the fresh corn kernels in an environment of -40°C to -30°C for 8 to 10 hours; 3. Use quick-frozen fresh corn kernels in a freezer at -15°C to -20°C The fresh corn kernel peeling machine performs peeling; 4. In step 3, keep the temperature in the grinding chamber of the quick-frozen fresh corn kernel peeling machine below -5° C.; 5. Remove the chaff.

specific Embodiment approach 2

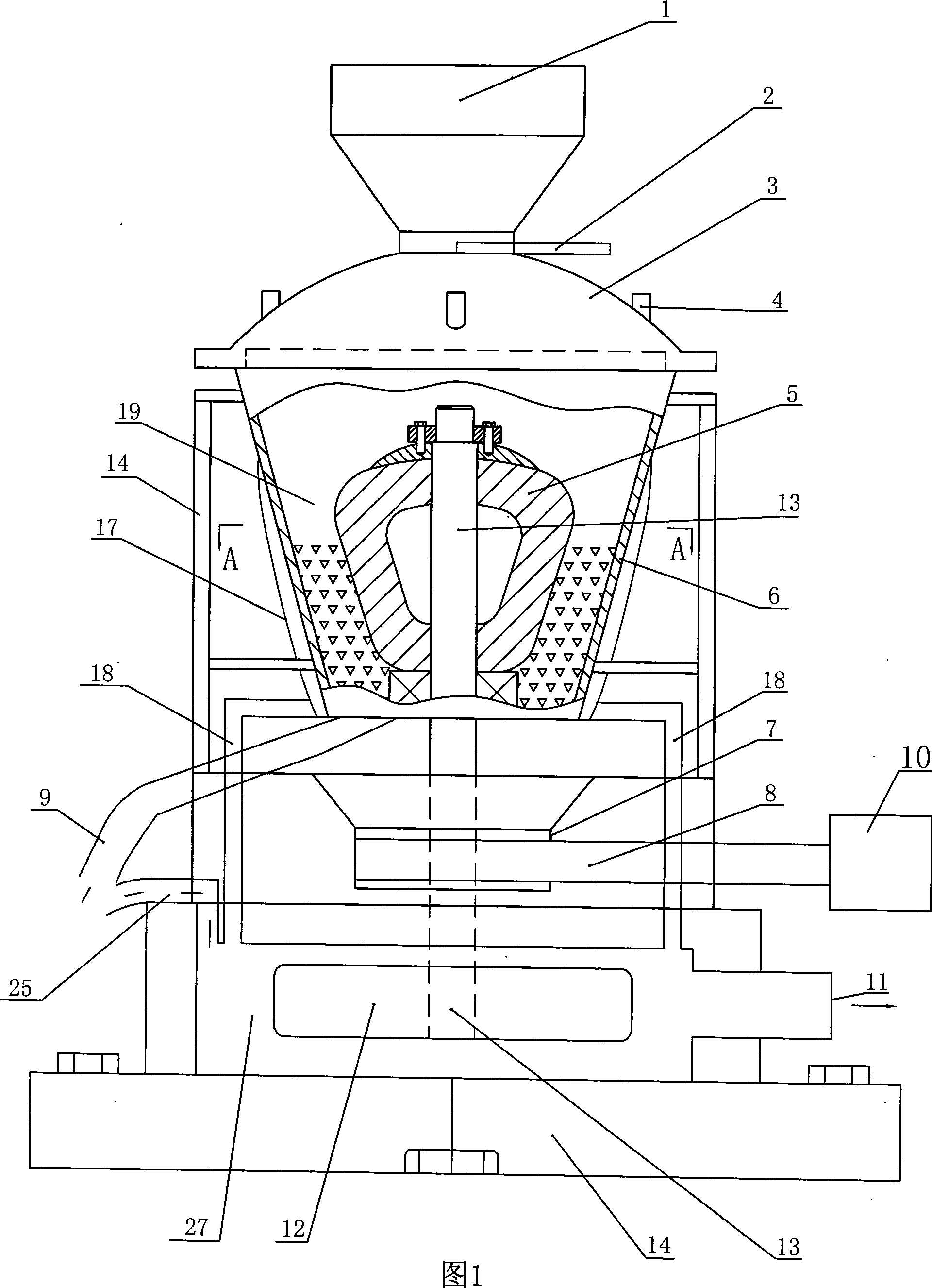

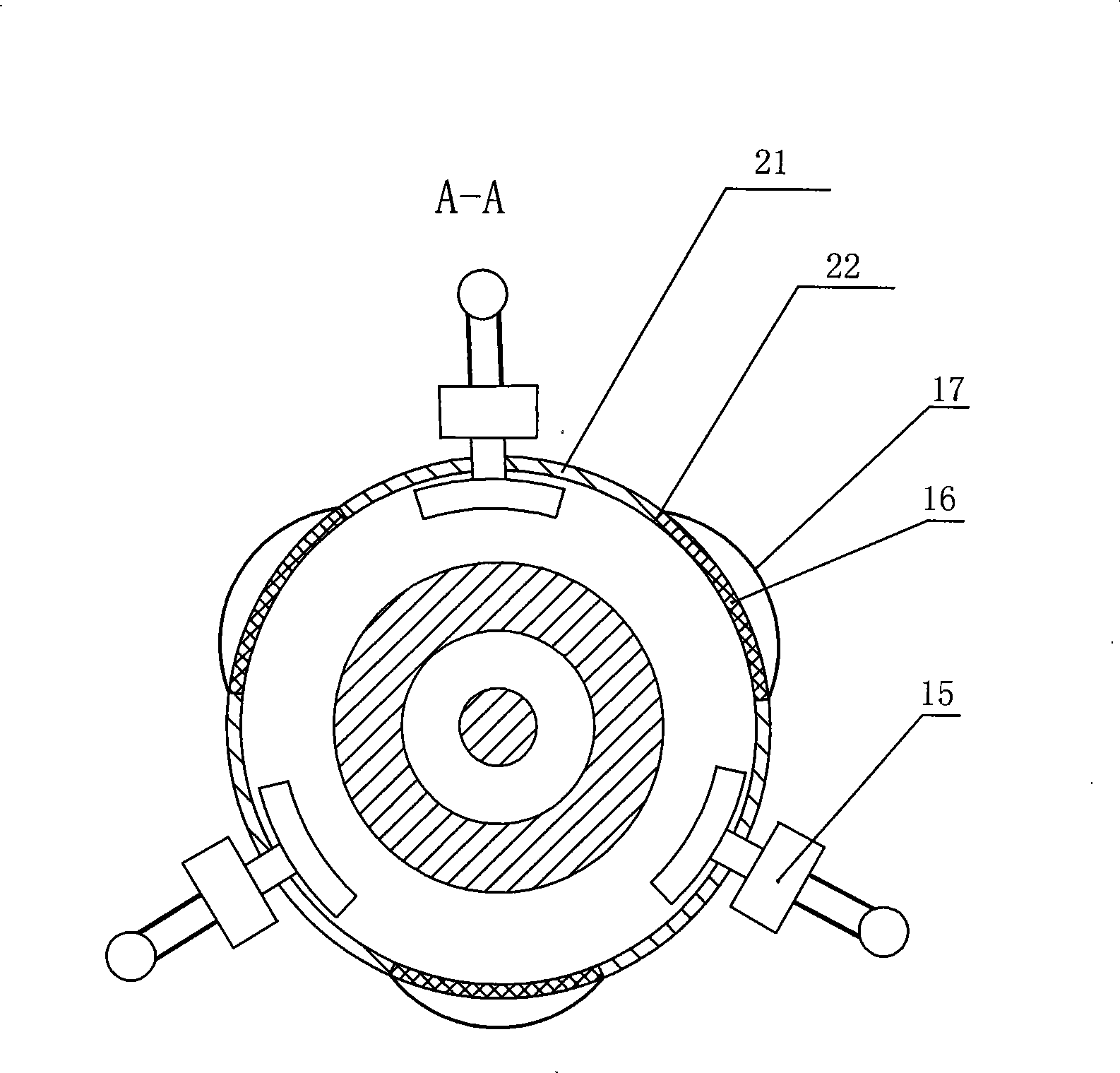

[0009] Specific implementation mode two: as shown in Figure 1 and figure 2 As shown, the quick-frozen fresh corn grain peeling machine of the present embodiment is made of feed hopper 1, flat belt pulley 7, flat belt 8, motor 10, fan 12, fixed mount 14, discharge pipe 9, bran bark output pipe 18, go out bran bark Port 11, grinding wheel 5, grinding container 6, sealing cover 3, shaft 13, cooling air inlet 4, the bottom end of the feeding funnel 1 is connected with the upper end of sealing cover 3, and the sealing cover 3 is covered on the upper end of grinding container 6 , the grinding container 6 is fixedly connected with the fixed frame 14, the bottom surface of the grinding container 6 passes through the top of the shaft 13 and is connected with the shaft 13 in rotation, the grinding wheel 5 is located in the grinding container 6, the grinding wheel 5, the flat pulley 7, and the fan 12 are pressed The sequence from top to bottom is fixedly installed on the shaft 13 success...

specific Embodiment approach 3

[0010] Specific implementation mode three: as shown in Figure 1 and figure 2 As shown, three cooling air inlets 4 are uniformly arranged on the sealing cover 3 in this embodiment. Such a design can achieve the purpose of sufficient cooling. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com