Low-melting-point compound suspending agent and preparation method thereof

A compound and low melting point technology, applied in botany equipment and methods, animal repellants, plant growth regulators, etc., can solve the problems of easy melting or softening, low melting point, deterioration of physical properties, etc., and achieve physical stability Qualified, good fluidity, good physical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: prepare 1% beta-cypermethrin suspension concentrate

[0034] The mass percent of each component is as follows:

[0035]

[0036] Preparation:

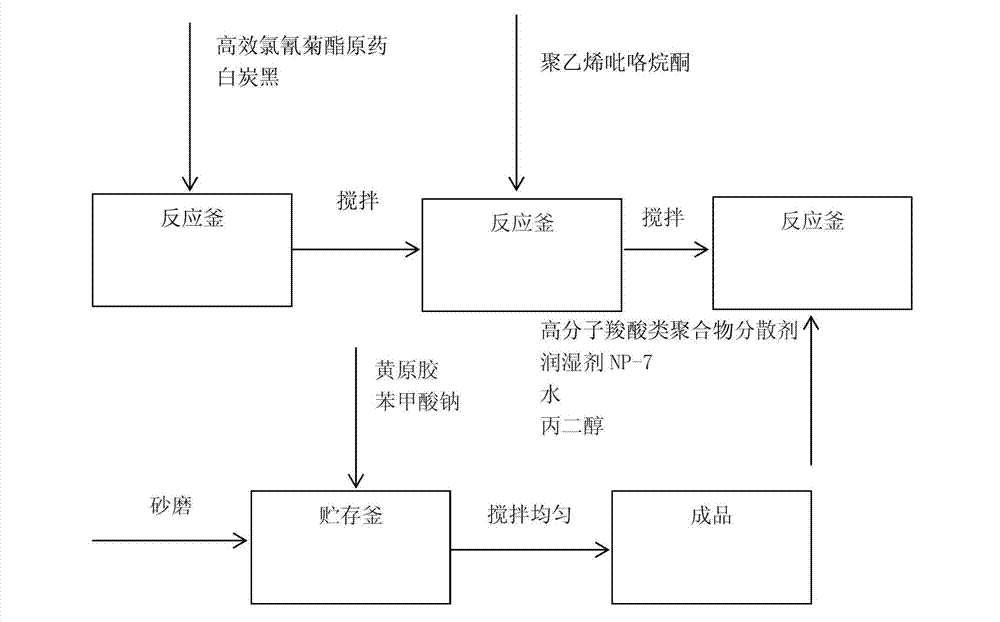

[0037] Mix beta-cypermethrin and white carbon black evenly, add polyvinylpyrrolidone and mix evenly, then add appropriate amount of water, put the mixture in a stirring tank, add high molecular carboxylic acid polymer dispersant, wetting agent NP-7 , propylene glycol, and mix well. Then turn on the sand mill and perform sand grinding under the condition of ≤40° C. to obtain a sand grinding liquid with a particle size between 1 μm and 5 μm. Then add the pre-prepared xanthan gum liquid with a mass concentration of 4% and sodium benzoate into the sanding liquid, and stir evenly to obtain a 1% beta-cypermethrin suspending agent. Process flow chart see figure 1 .

Embodiment 2

[0038] Embodiment 2: prepare 10% beta-cypermethrin suspension concentrate

[0039] The weight percent of each component:

[0040]

[0041] Preparation:

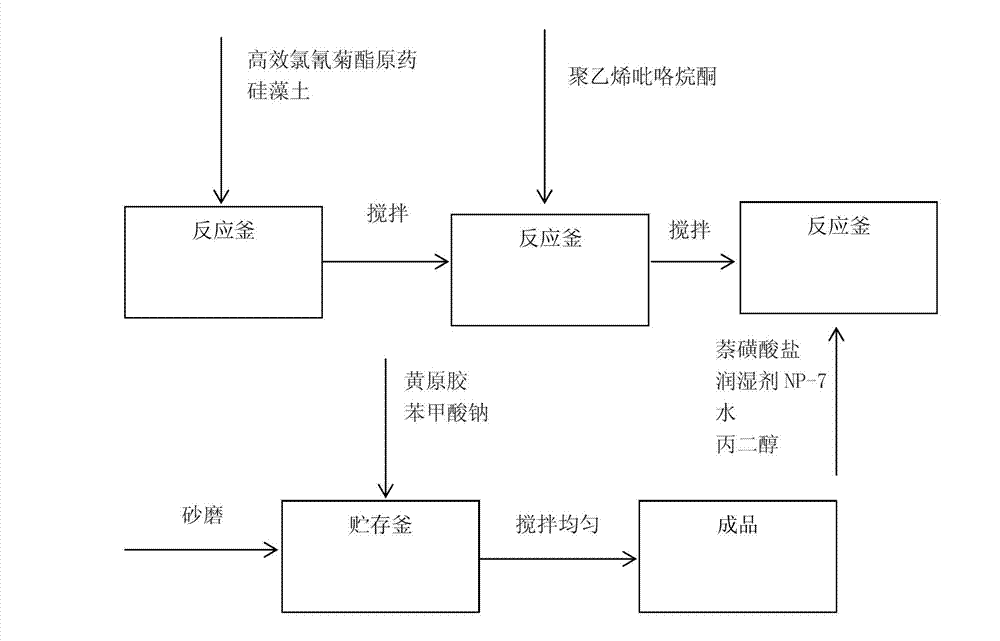

[0042] Mix beta-cypermethrin and diatomaceous earth evenly, add polyvinylpyrrolidone and mix evenly, then add appropriate amount of water, put the mixture in a stirring tank, add naphthalenesulfonate dispersant, wetting agent NP-7, propylene glycol, mix uniform. Then turn on the sand mill and perform sand grinding under the condition of ≤40° C. to obtain a sand grinding liquid with a particle size between 1 μm and 5 μm. Then add the pre-prepared xanthan gum liquid with a mass concentration of 4% and sodium benzoate into the sanding liquid, and stir evenly to obtain a 30% beta-cypermethrin suspension concentrate. Process flow chart see figure 2 .

Embodiment 3

[0043] Embodiment 3: prepare 30% pendimethalin suspension

[0044] The weight percent of each component:

[0045]

[0046]

[0047] Preparation:

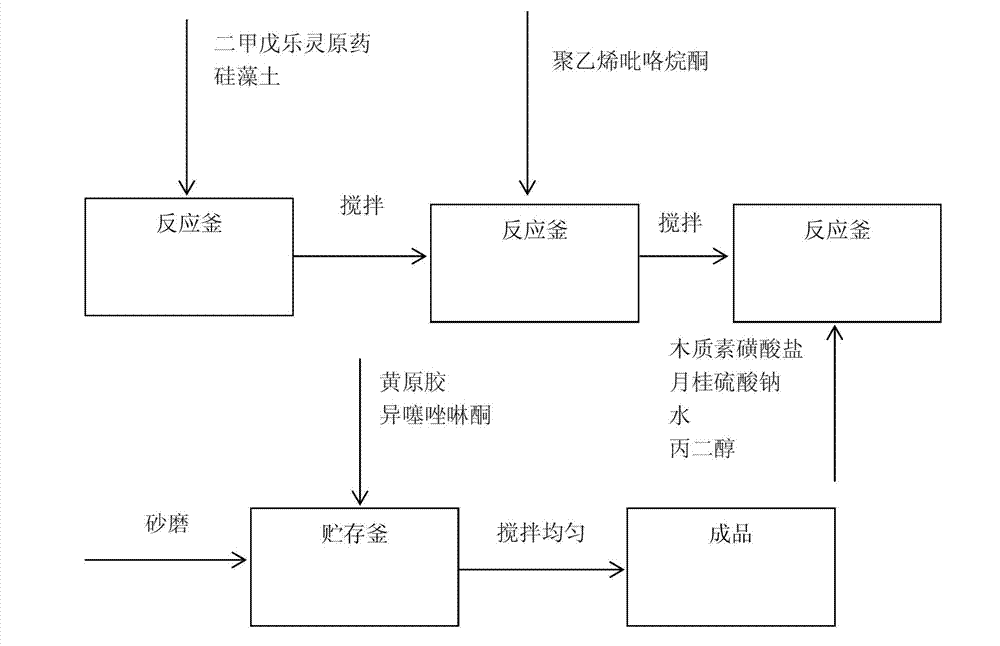

[0048]Pendimethalin original drug and diatomite are mixed evenly, then polyvinylpyrrolidone is added to mix evenly, then an appropriate amount of water is added, the mixture is placed in a stirring tank, and lignosulfonate dispersant and wetting agent lauryl sulfuric acid are added Sodium, propylene glycol, mix well. Then turn on the sand mill and perform sand grinding under the condition of ≤40° C. to obtain a sand grinding liquid with a particle size between 1 μm and 5 μm. Then add the pre-prepared xanthan gum liquid with a mass concentration of 4% and isothiazolinone into the sanding liquid, and stir evenly to obtain a 30% pendimethalin suspension. Process flow chart see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com