Laser beam processing machine

A technology for laser processing and processed objects, applied in auxiliary devices, laser welding equipment, metal processing equipment, etc., to achieve the effect of suppressing heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

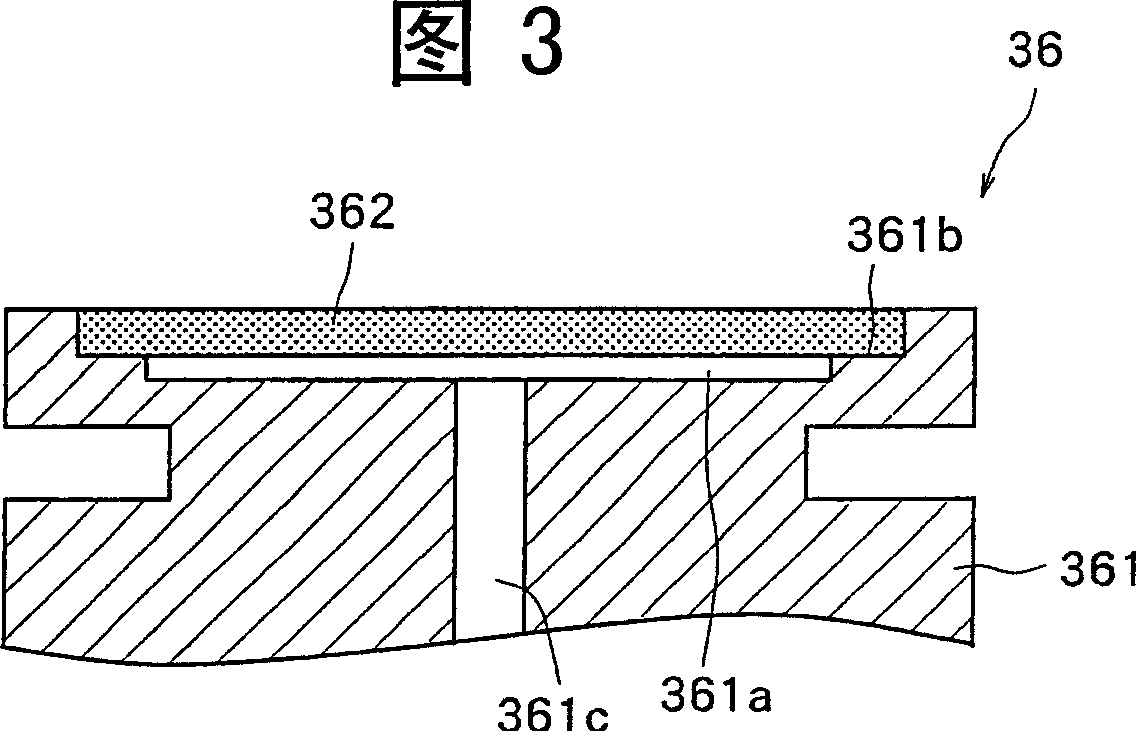

[0066] Figure 12 The chuck table 7 shown in FIG. 13 is composed of an electrostatic chuck table, including a cylindrical electrostatic chuck table body 71, an electrode 72 arranged on the upper surface of the electrostatic chuck table body 71, and an electrode 72 stacked on the electrode 72. The workpiece holding member 73 on the As shown in FIG. 13, the main body 71 is formed of a metal material such as stainless steel, and a circular fitting recess 71a is provided on its upper surface.

[0067] The electrodes 72 are mounted on the upper surface of an insulating support substrate 74 provided in cooperation with the mounting recess 71 a provided on the upper surface of the electrostatic chuck stage main body 71 . The insulating support substrate 74 is formed of an insulating material such as alumina, and has a mounting recess 74a on its upper surface, and the electrode 72 is provided in cooperation with the mounting recess 74a. Thus, the electrode 72 mounted on the upper su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com