Tungsten alloy shield plate and preparation method thereof

A technology of shielding plate and tungsten alloy, which is applied in the field of tungsten alloy shielding plate and its preparation, can solve the problems of difficult to meet the demand and poor shielding performance of tungsten alloy, and achieve good neutron absorption performance, good conductivity and good conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

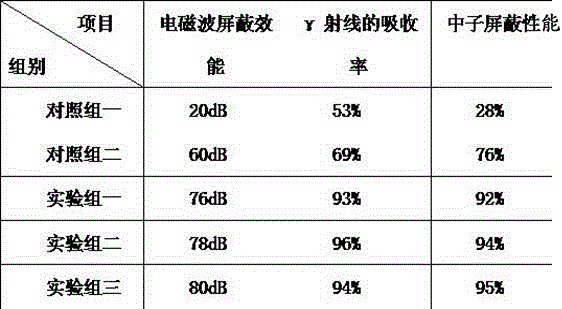

Examples

Embodiment 1

[0037] A tungsten alloy shielding plate, comprising raw materials in the following proportions by weight: 140 parts of tungsten powder, 10 parts of nickel powder, 50 parts of copper powder, 20 parts of samarium powder, 2 parts of neodymium powder, 10 parts of silver powder, and 2 parts of yttrium oxide , 10 parts of molybdenum wire, 10 parts of rhenium wire and 3 parts of tin oxide.

[0038] A kind of preparation method of tungsten alloy shielding plate comprises the following steps:

[0039] 1) Pour 140 parts of tungsten powder, 10 parts of nickel powder, 50 parts of copper powder, 20 parts of samarium powder, 2 parts of neodymium powder, 10 parts of silver powder, 2 parts of yttrium oxide and 3 parts of tin oxide into the container, and then place Carry out drying treatment in a vacuum heating furnace at a drying temperature of 70°C, a vacuum degree of 5 Pa, and a drying time of 9 minutes to obtain dry powder for later use;

[0040] 2) Pour the dry powder prepared in step 1...

Embodiment 2

[0048]A tungsten alloy shielding plate, comprising raw materials in the following proportions by weight: 200 parts of tungsten powder, 70 parts of nickel powder, 120 parts of copper powder, 80 parts of samarium powder, 8 parts of neodymium powder, 16 parts of silver powder, and 8 parts of yttrium oxide , 16 parts of molybdenum wire, 16 parts of rhenium wire and 9 parts of tin oxide.

[0049] A preparation method of a tungsten alloy shielding plate, comprising the following steps:

[0050] 1) Pour 200 parts of tungsten powder, 70 parts of nickel powder, 120 parts of copper powder, 80 parts of samarium powder, 8 parts of neodymium powder, 16 parts of silver powder, 8 parts of yttrium oxide and 9 parts of tin oxide into the container, and then put Carry out drying treatment in a vacuum heating furnace at a drying temperature of 90°C, a vacuum degree of 7Pa, and a drying time of 11 minutes to obtain dry powder for later use;

[0051] 2) Pour the dry powder prepared in step 1) int...

Embodiment 3

[0059] A tungsten alloy shielding plate, comprising raw materials in the following proportions by weight: 170 parts of tungsten powder, 40 parts of nickel powder, 80 parts of copper powder, 50 parts of samarium powder, 5 parts of neodymium powder, 13 parts of silver powder, and 5 parts of yttrium oxide , 13 parts of molybdenum wire, 13 parts of rhenium wire and 6 parts of tin oxide.

[0060] A preparation method of a tungsten alloy shielding plate, comprising the following steps:

[0061] 1) Pour 170 parts of tungsten powder, 40 parts of nickel powder, 80 parts of copper powder, 50 parts of samarium powder, 5 parts of neodymium powder, 13 parts of silver powder, 5 parts of yttrium oxide and 6 parts of tin oxide into the container, and then place Carry out drying treatment in a vacuum heating furnace at a drying temperature of 80°C, a vacuum degree of 6 Pa, and a drying time of 10 minutes to obtain dry powder for later use;

[0062] 2) Pour the dry powder prepared in step 1) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com