Preparation method of high-temperature-resistant grid acrylic pressure-sensitive adhesive tape

An acrylic pressure-sensitive adhesive tape, acrylic pressure-sensitive adhesive technology, applied in the direction of pressure-sensitive film/sheet, adhesive, film/sheet-like adhesive, etc., can solve the problem of insufficient temperature resistance, achieve easy operation, ensure the surface Exhaust performance, the effect of improving the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

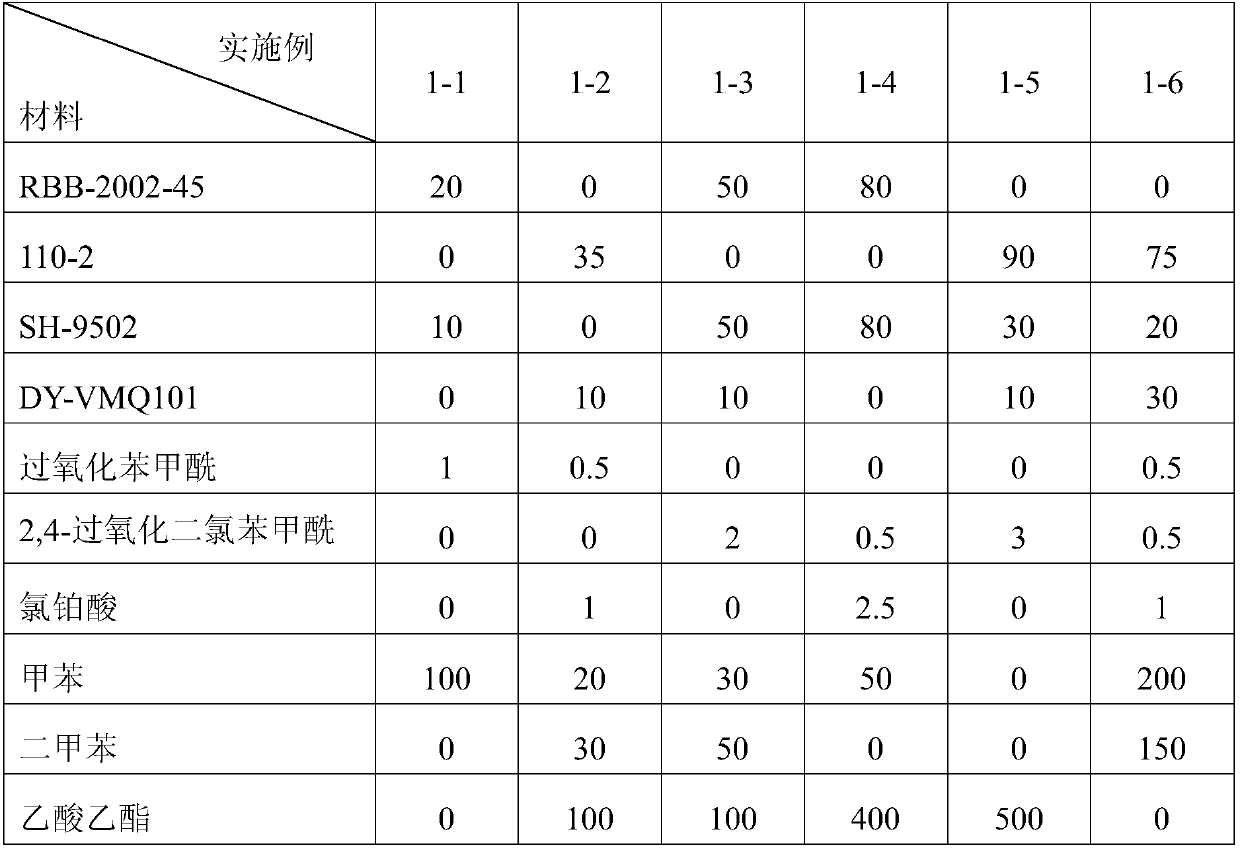

[0027] Preparation of the first part silicone resin coating material

[0028] Basic process: add 20-90 parts by mass of silicone rubber, 10-80 parts by mass of silicone resin, 1-3 parts by mass of catalyst, and 100-500 parts by mass of solvent into the reaction kettle, stir and mix evenly to obtain a silicone resin coating Material;

[0029] Silicone rubber adopts Dow Chemical Company's XIAMETER TM RBB-2002-45 silicone elastomer or 110-2 silicone elastomer of Hoshine Silicon Industry Co., Ltd.;

[0030] The silicone resin is one or two of SH-9502 methyl silicone resin from Hubei New Sihai Chemical Co., Ltd. and DY-VMQ101 methyl vinyl silicone resin from Shandong Dayi Chemical Co., Ltd.;

[0031] Catalyst adopts benzoyl peroxide, 2,4-dichlorobenzoyl peroxide, chloroplatinic acid (H 2 PtCl 6 ) one or more of the catalysts;

[0032] Solvent adopts one or more in toluene, xylene, ethyl acetate;

[0033] Embodiment 1-1~1-6 See the following table for the materials and consump...

Embodiment 5

[0052] A preparation method of high temperature resistant grid acrylic pressure-sensitive adhesive tape, comprising the following steps:

[0053] a. Preparation of silicone resin coating material:

[0054] Add 20 parts by mass of silicone rubber, 10 parts by mass of silicone resin, 1 part by mass of catalyst and 100 parts by mass of solvent into the reaction kettle, stir and mix evenly to obtain a silicone resin coating material;

[0055] The silicone rubber is one of the organosilicon elastomers mainly composed of dimethylsiloxane polymer;

[0056] Described catalyst is benzoyl peroxide, 2,4-dichlorobenzoyl peroxide and chloroplatinic acid (H 2 PtCl 6 ) one or a mixture of two or more catalysts;

[0057] The solvent is one or a mixture of two or more of toluene, xylene, and ethyl acetate;

[0058] b. Preparation of PET pre-coated film:

[0059] On the coating machine, the film surface treatment agent is evenly coated on the PET film with a thickness of 25 μm and a width ...

Embodiment 6

[0067] A preparation method of high temperature resistant grid acrylic pressure-sensitive adhesive tape, comprising the following steps:

[0068] a. Preparation of silicone resin coating material:

[0069] Add 90 parts by mass of silicone rubber, 80 parts by mass of silicone resin, 3 parts by mass of catalyst and 500 parts by mass of solvent into the reaction kettle, stir and mix evenly to obtain a silicone resin coating material;

[0070] The silicone rubber is one of the organosilicon elastomers mainly composed of dimethylsiloxane polymer;

[0071] Described catalyst is benzoyl peroxide, 2,4-dichlorobenzoyl peroxide and chloroplatinic acid (H 2 PtCl 6 ) one or a mixture of two or more catalysts;

[0072] The solvent is one or a mixture of two or more of toluene, xylene, and ethyl acetate;

[0073] b. Preparation of PET pre-coated film:

[0074] On the coating machine, the film surface treatment agent is evenly coated on the PET film with a thickness of 250 μm and a widt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com