Polylactic acid film or sheet

A polylactic acid and film technology, applied in the field of polylactic acid-based films or sheets, separator films, adhesive tapes or sheets, and can solve the problems of film or sheet breakage, cracking, separator breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

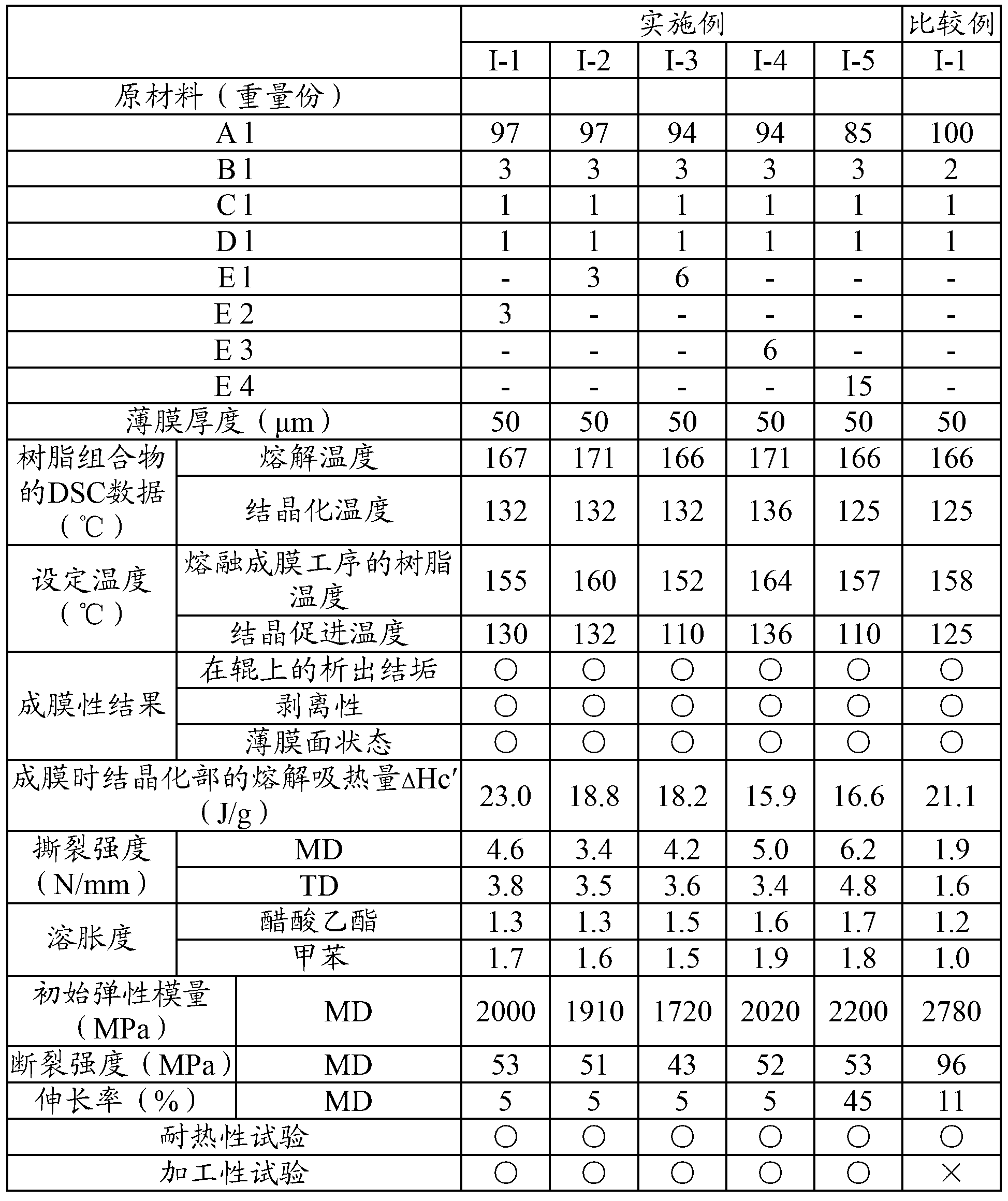

[0214] Examples and comparative examples are given below to further describe the present invention in detail. The present invention is not limited by them in any way. In addition, the evaluation in an Example etc. was performed as follows.

[0215] Materials used in Examples and the like are shown below.

[0216]

[0217] A1: Product name "TERRAMAC TP-4000" (manufactured by UNITIKA LTD.)

[0218]

[0219] B1: Acrylic modified polytetrafluoroethylene (trade name "METABLEN A-3000", manufactured by Mitsubishi Rayon Co., Ltd.)

[0220]

[0221] C1: Zinc phenylphosphonate (trade name "ECOPROMOTE", manufactured by Nissan Chemical Industries, Ltd.)

[0222]

[0223] D1: Modified polypropylene containing maleic anhydride groups (weight average molecular weight 32,000, acid value 52 mgKOH / g, trade name "Umex 1010", manufactured by Sanyo Chemical Industry Co., Ltd.)

[0224]

[0225] E1: Polyglycerol fatty acid ester (number average molecular weight Mn1000, trade name "CHIRA...

Embodiment I-1

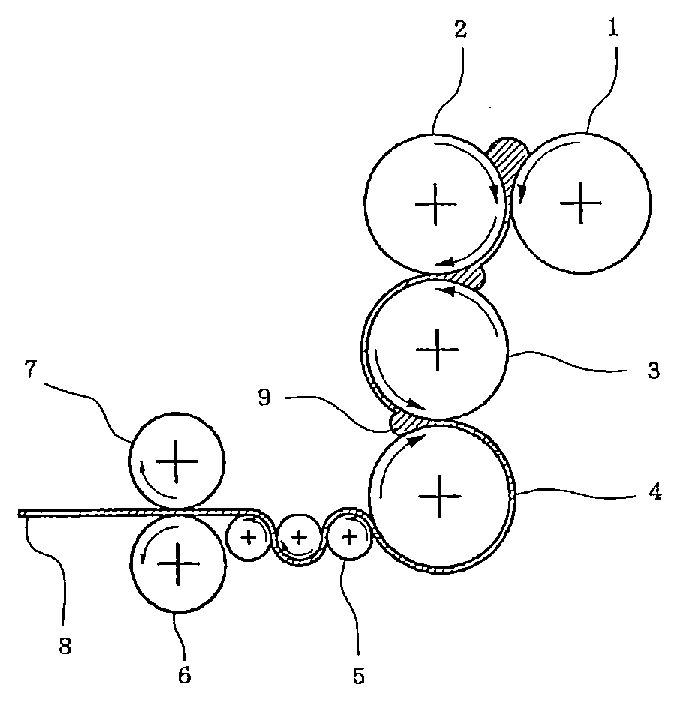

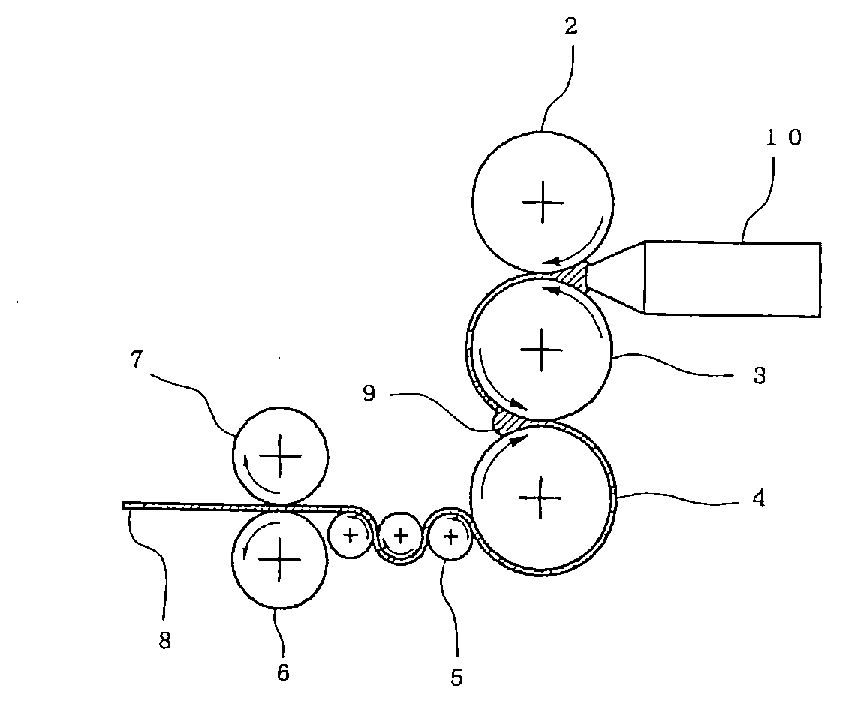

[0230] Prepare the resin composition according to the compounding ratio shown in the following Table 1, melt and knead with a Banbury mixer, and then use an inverted L-shaped 4-roller calender to perform calendering to form a film to a thickness of 50 μm (melt film forming process ). Next, if figure 1 As shown, after the melting film forming process, three rolls (leading rolls) that can be heated to any temperature are arranged immediately, so that the resin composition melted and formed into a film can pass alternately up and down, thereby promoting crystallization (crystallization promoting process ). Then, the resin composition is solidified by passing through cooling rolls to form a film. The temperature of the resin composition in the melt film forming process (resin temperature at the time of melt film forming) is set to be equivalent to figure 1 The surface temperature of the 4th roll in the 4th roll. In addition, regarding the temperature of the resin composition...

Embodiment I-2~I-5

[0232] Resin compositions were prepared according to the compounding ratios shown in the following Table 1, and films of Examples I-2 to I-5 were prepared in the same manner as in Example I-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com