Backlight module and display device

A technology for a backlight module and a light source module, which is applied to identification devices, lighting devices, fixed lighting devices, etc., can solve the problems that the light-emitting diodes 6 cannot be lit by melting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

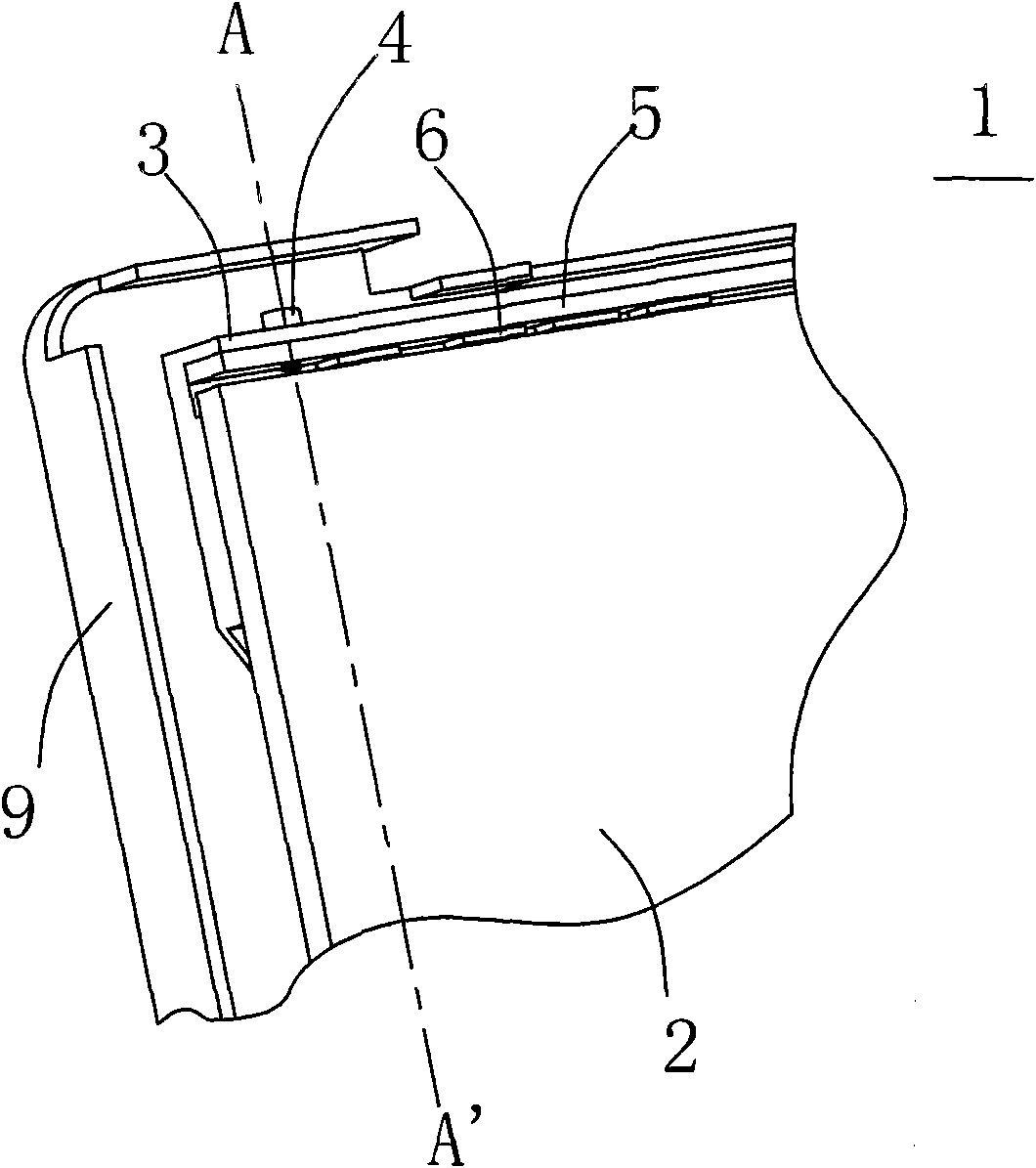

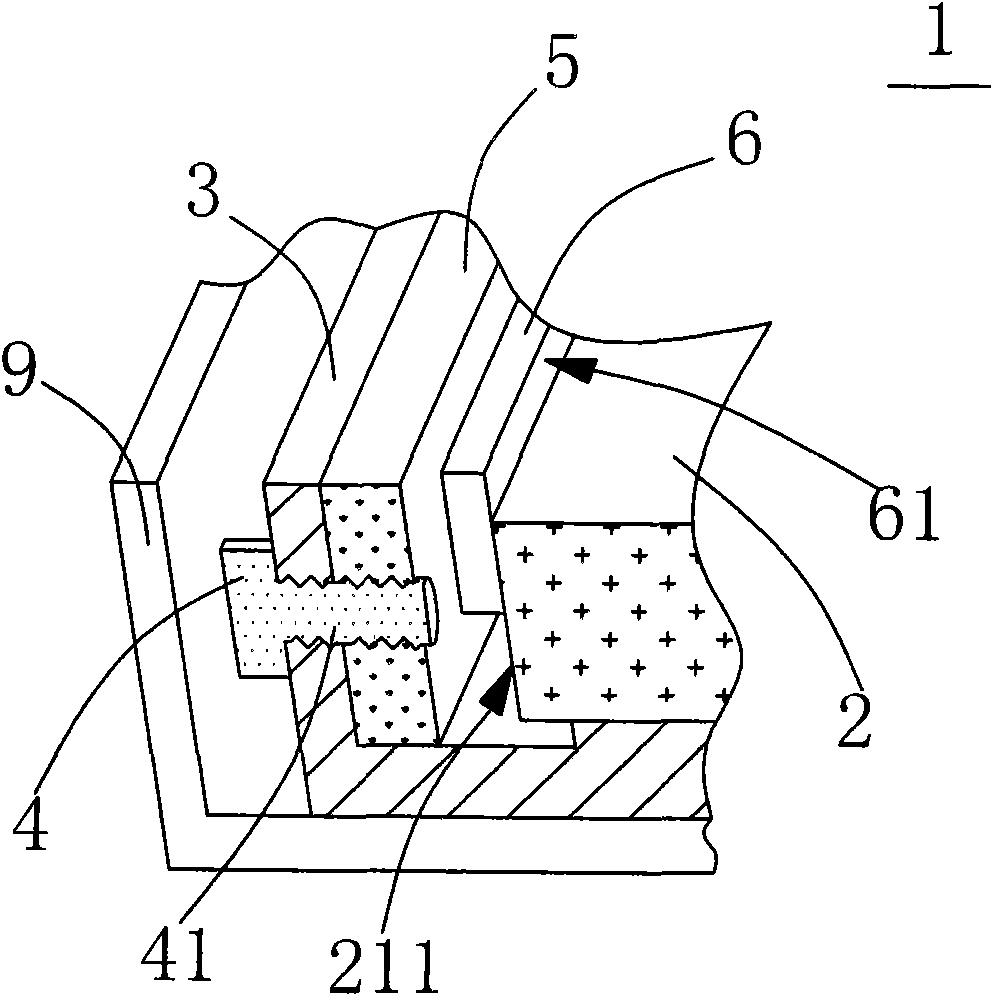

[0028] See figure 2 and image 3 , figure 2 Shown is a schematic diagram of a fixture according to the invention, image 3 Shown is an exploded schematic view of the backlight module according to the present invention. The present invention provides a display device, which includes a display panel and a backlight module 10, and the backlight module 10 provides a backlight for the display panel. The backlight module 10 includes a light source module, a frame body 12 , at least one fixing part 13 and an elastic element 14 . The light source module includes a circuit board 15 and at least one LED 16 electrically disposed on the first surface 51 of the circuit board 15. The circuit board 15 has at least one first fixing hole 53. The circuit board 15 has the first surface 51 and the first surface 51. Two surfaces 52 , wherein in this embodiment, the first surface 51 is opposite to the second surface 52 . But in fact, the first surface 51 and the second surface 52 may also be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com