Silicon core furnace repeatedly pulling multiple silicon cores in one heat

A technology of silicon core furnace and silicon core, which is applied in the field of carrier-silicon core device and silicon core furnace, can solve the problems of manpower, material resources and energy consumption, and low output of a single furnace, so as to reduce manpower, energy consumption, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the drawings and specific embodiments.

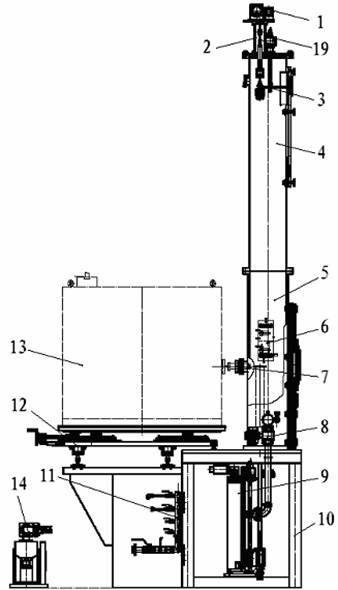

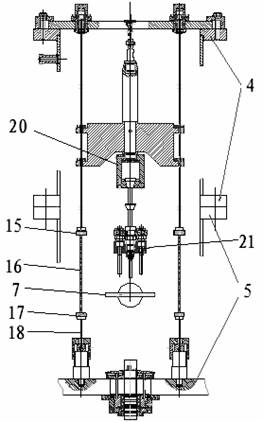

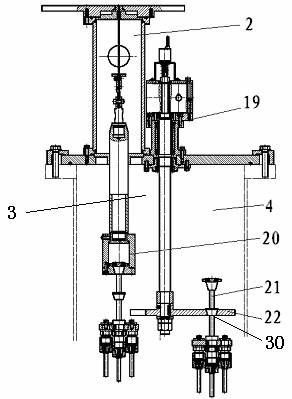

[0017] Such as figure 1 , figure 2 The silicon core furnace structure of the device of the present invention is that a lower transmission device 9 and a water cooling device 11 are arranged in the frame 10, and the lower furnace chamber 5 and the trough road block 12 are installed on the table and the rear of the frame 10. The road block 12 is provided with a high-frequency tank 13 connected to a high-frequency power supply. The lower furnace chamber 5 is provided with an inflator 6, a high-frequency electrode and induction heating assembly 7, and an evacuation device 8. The inflator 6 is connected to the outside The high-frequency electrode and induction heating assembly 7 are connected to the high-frequency tank circuit 13, the evacuation device 8 is connected to the external vacuum pump 14; the lower furnace chamber 5 is connected upward with the upper furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com