Sawtooth jet type evacuator

A sawtooth and nozzle technology, applied in the direction of jet pumps, jet devices, jet devices, etc., can solve the problems of large steam consumption, small steam consumption, no research on improving the injection coefficient and evacuation efficiency of steam ejectors, etc. Improvement of injection coefficient and work efficiency, effect of improved flow form, high injection coefficient and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

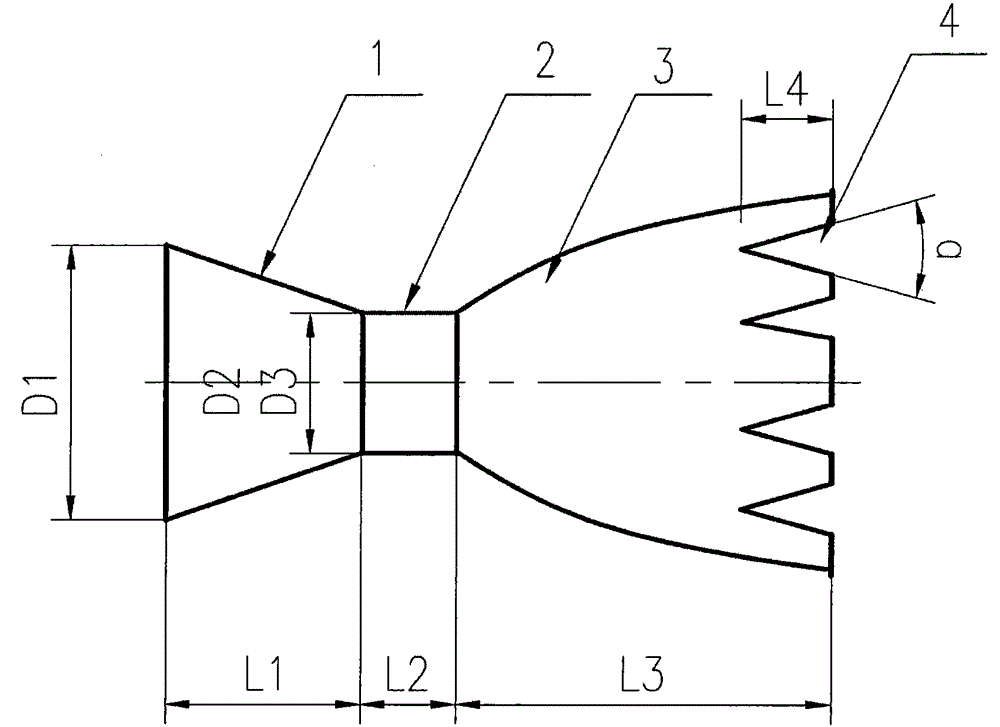

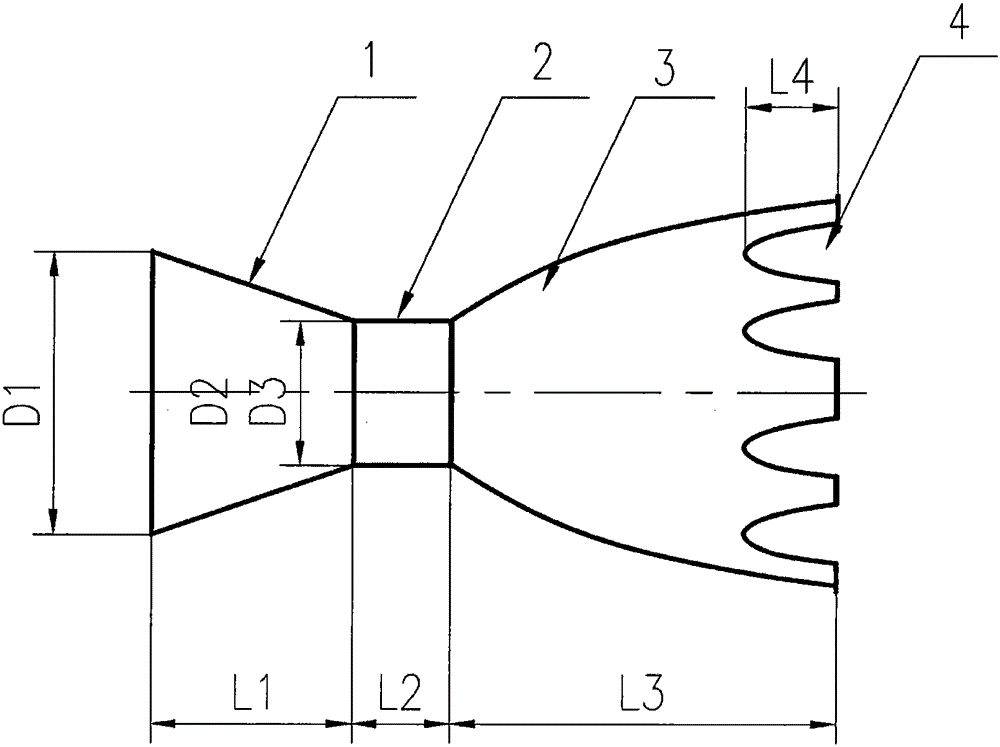

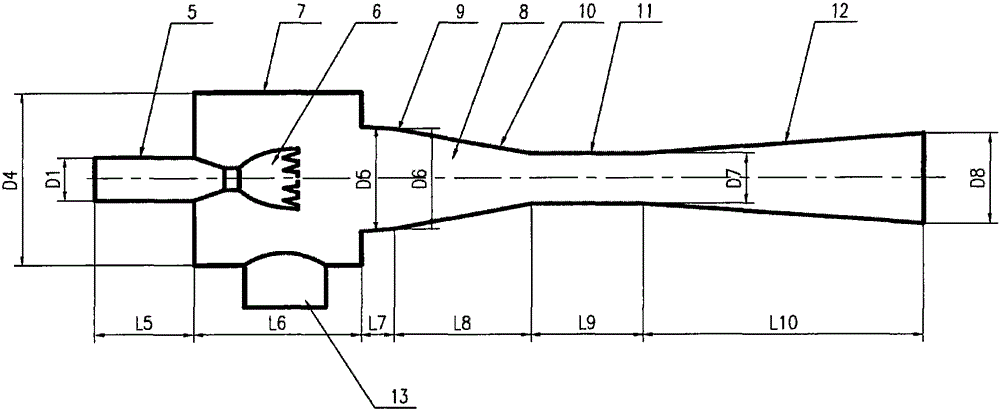

[0022] Will figure 1 or figure 2 The 3 parts of the serrated nozzle: the nozzle inlet section ( figure 1 , 2 Symbol 1), nozzle throat ( figure 1 , 2 Symbol 2), nozzle outlet section ( figure 1 , 2 Symbol 3) are connected in sequence to form a complete supersonic sawtooth nozzle structure. Then, the complete supersonic sawtooth nozzle ( image 3 Symbol 6) is installed in the suction chamber ( image 3 In the symbol 7), the inlet section of the sawtooth nozzle ( figure 1 , 2 Symbol 1) and the inlet section of the mainstream fluid (such as water vapor, air, process fluid) pipeline ( image 3 The joints in symbol 5) are welded, or gasketed and threaded, or gasketed and flanged; the process piping that needs to be sucked in the process device is welded, or gasketed and threaded, or gasketed Plate seal and flanged to the secondary inlet ( image 3 Middle symbol 13); the outlet of the diffuser section of the mixing diffuser chamber ( image 3 The middle symbol 12) is we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com