Improved method for making vacuum switch device

A technology of vacuum switch and vacuum pump, which is applied in the direction of electric switch, high voltage/high current switch, high voltage air circuit breaker, etc. It can solve the problems of high investment, high product cost, long process time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

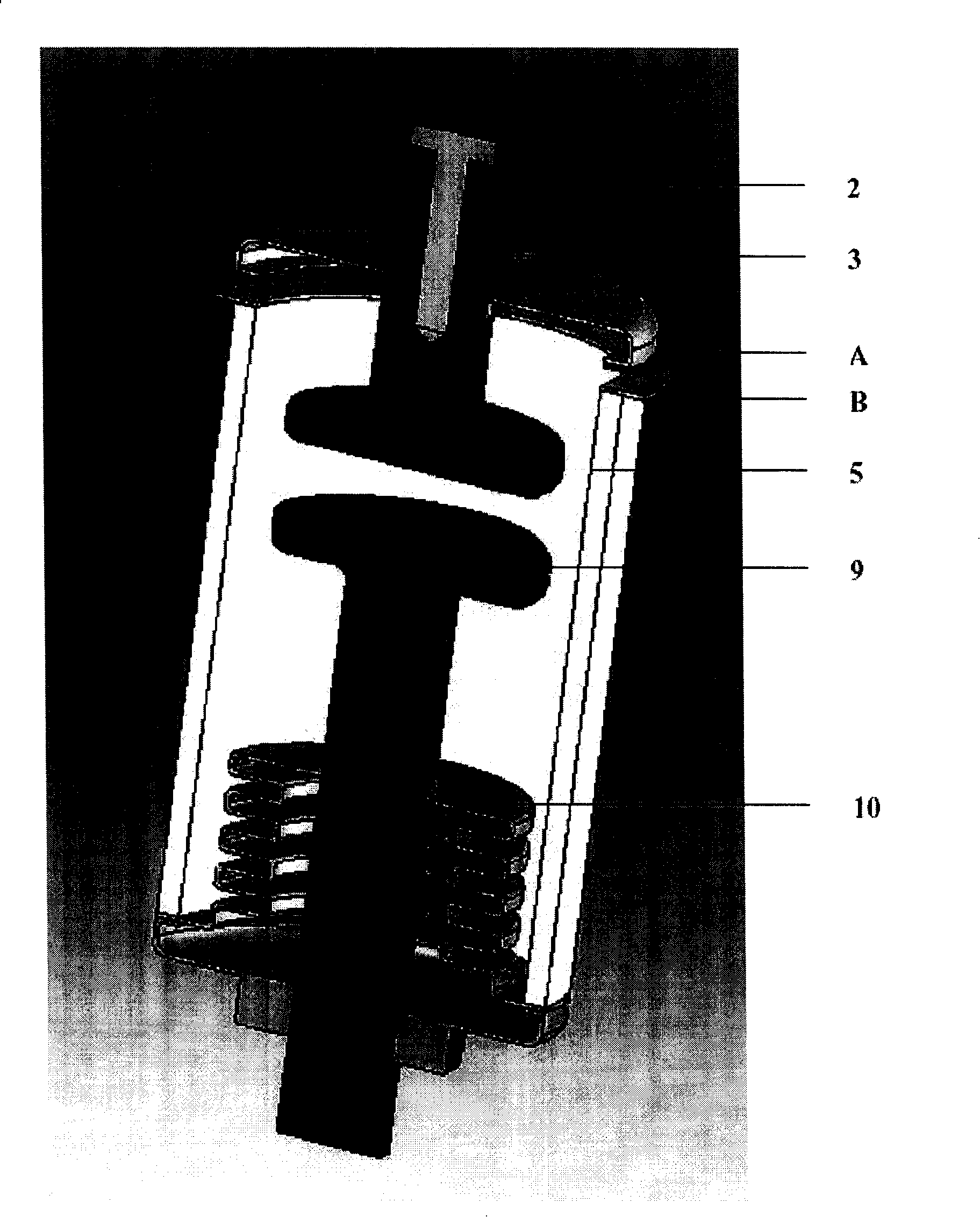

[0045] For this new method a small evacuated container is used, the inner dimensions of which only slightly exceed the outer dimensions of the vacuum chamber being evacuated.

[0046] These containers are connected to the high-efficiency vacuum pump with suitable hoses or pipes. These pumps can evacuate the vessel to the required vacuum within minutes while heating the vessel to 350°C to 400°C to remove all water molecules from the interior. In addition to chromium and copper, many conductor materials are allowed at this temperature.

[0047] All parts can be welded or soldered in advance, so only the two main parts are fed into the evacuated container for final welding.

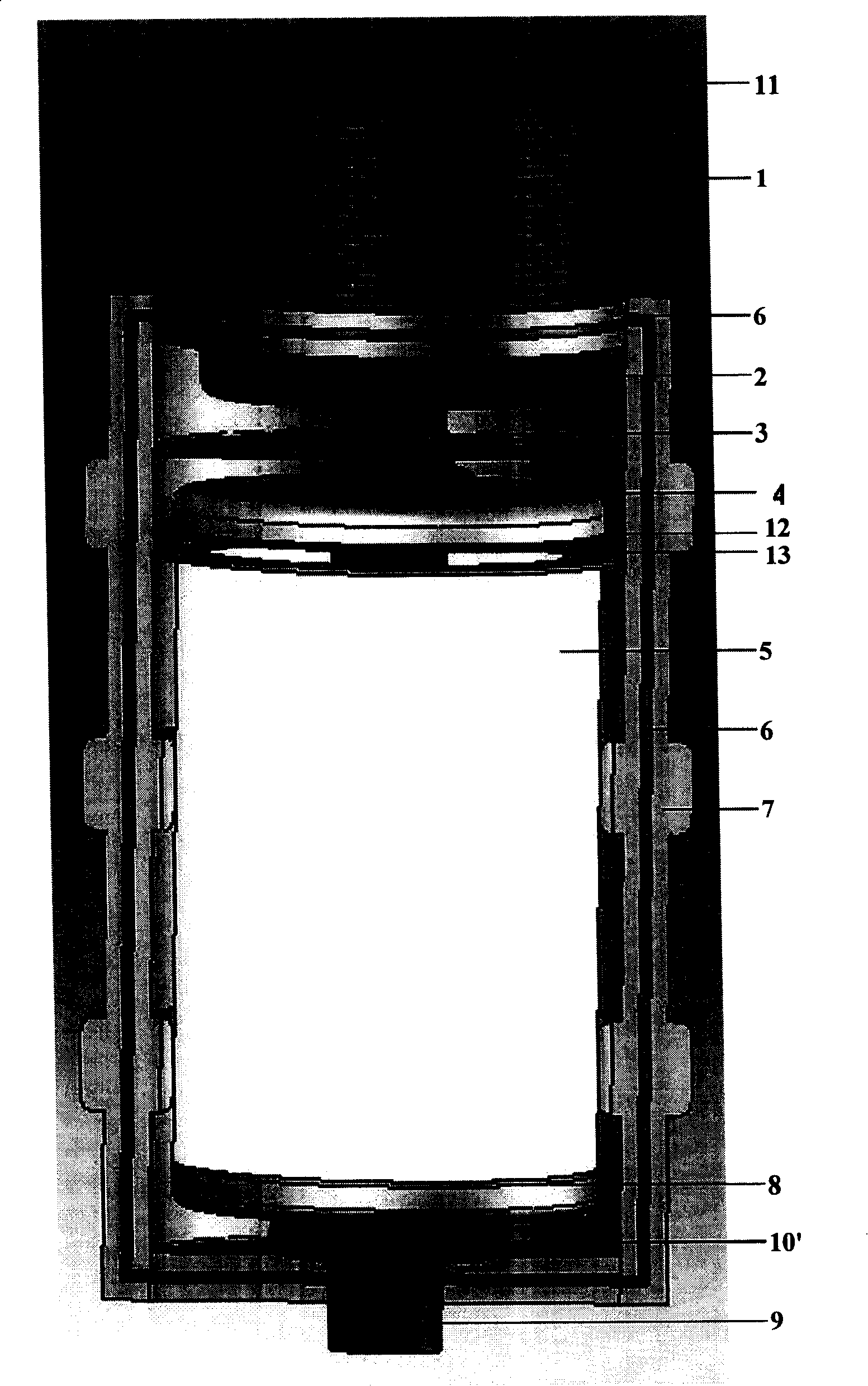

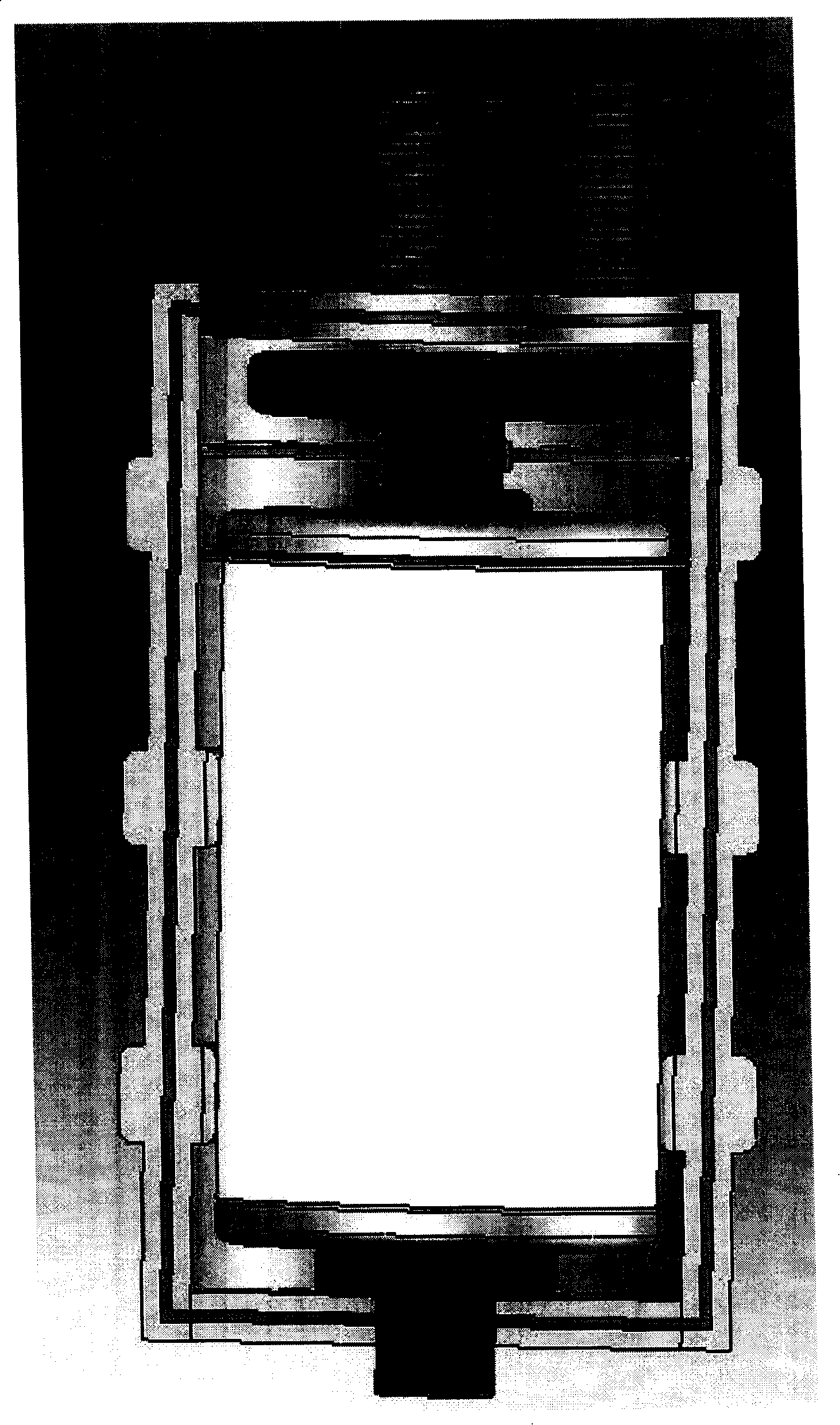

[0048] The vessel consists of two or more parts which can be closed by bringing them together after the parts of the vacuum chamber have been brought in (see figure 1 , container open).

[0049] The parts are fed into one of the container segments in the correct order, where they are supported by fixtures...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com