Device and method for for rapid warming of steam piping of a power plant

一种发电设备、蒸汽的技术,应用在机械设备、蒸汽机装置、发动机元件等方向,能够解决发电设备整体效率降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

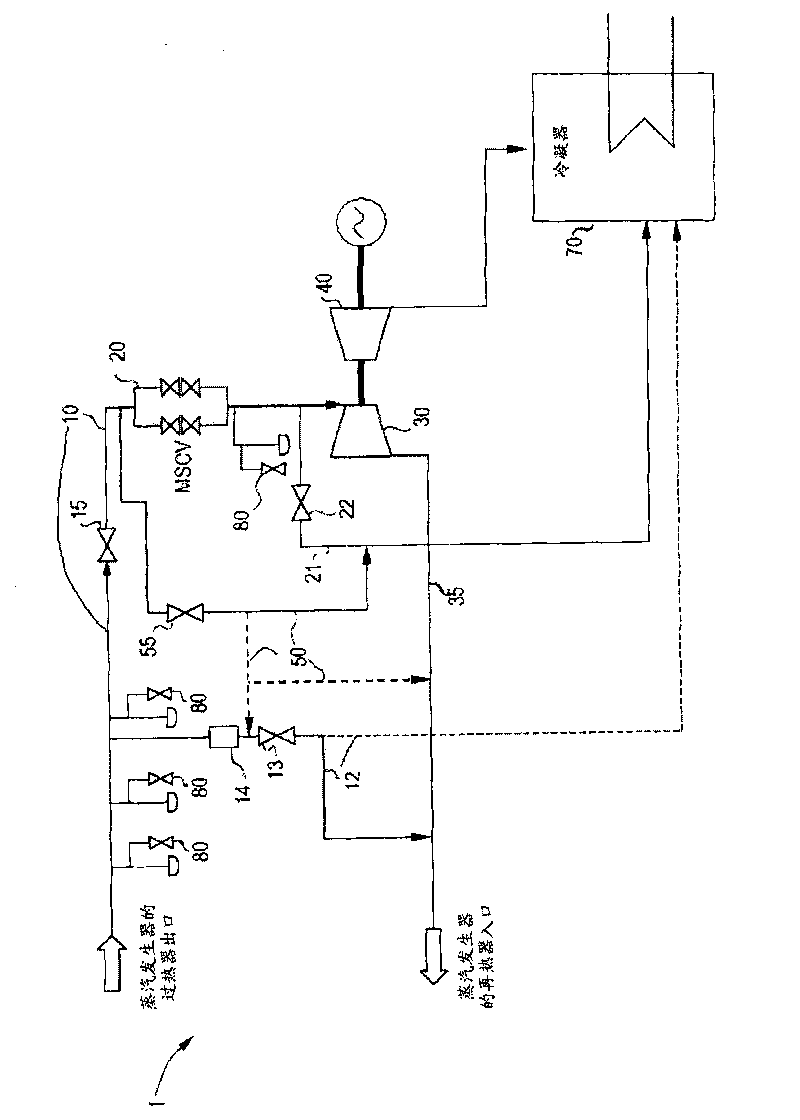

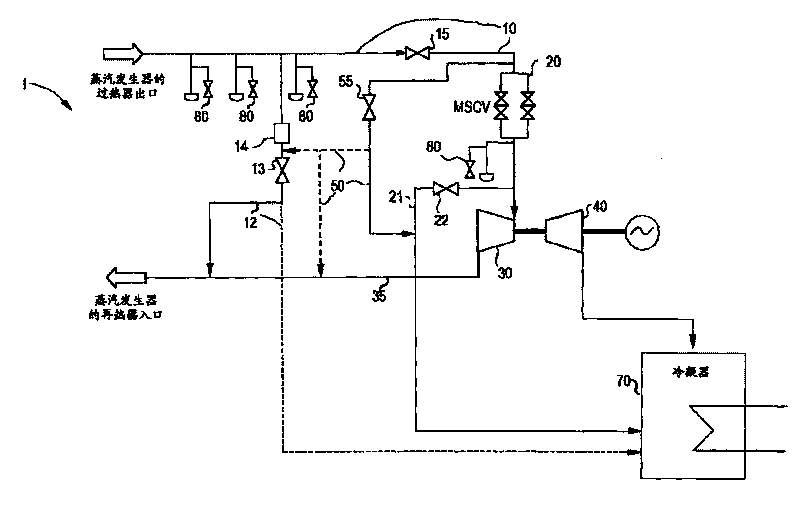

[0028] refer to figure 1 , provides a steam power plant 1, which includes flow piping, such as steam piping 10, thereby interconnecting a heat generator and a high-pressure steam turbine (HPST) 30, and a main steam control system arranged along the piping upstream of the HPST 30 A valve (MSCV) 20 to allow steam to enter the HPST 30 when the characteristics of the steam meet a threshold.

[0029] During start-up of the steam power plant 1 no steam is allowed to enter the HPST 30 unless the steam has a certain minimum temperature and / or a certain minimum pressure based on the operating specifications of the HPST 30 . At the start-up of the power plant 1, depending on the state before the start-up of the power plant, the pressure and temperature of the steam generated by the steam generator at the upstream of the MSCV 20 will not meet certain minimum values due to improper heating and discharge of the steam pipe 10 .

[0030] To ensure that the MSCV 20 is not opened until the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com