Metal working lubricant formulations based on supercritical carbon dioxide

A carbon dioxide and metal processing technology, applied in relevant problem areas, can solve waste disposal problems, reduce workshop air quality, worker impact and lung impact, etc., to increase tool life and ensure surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

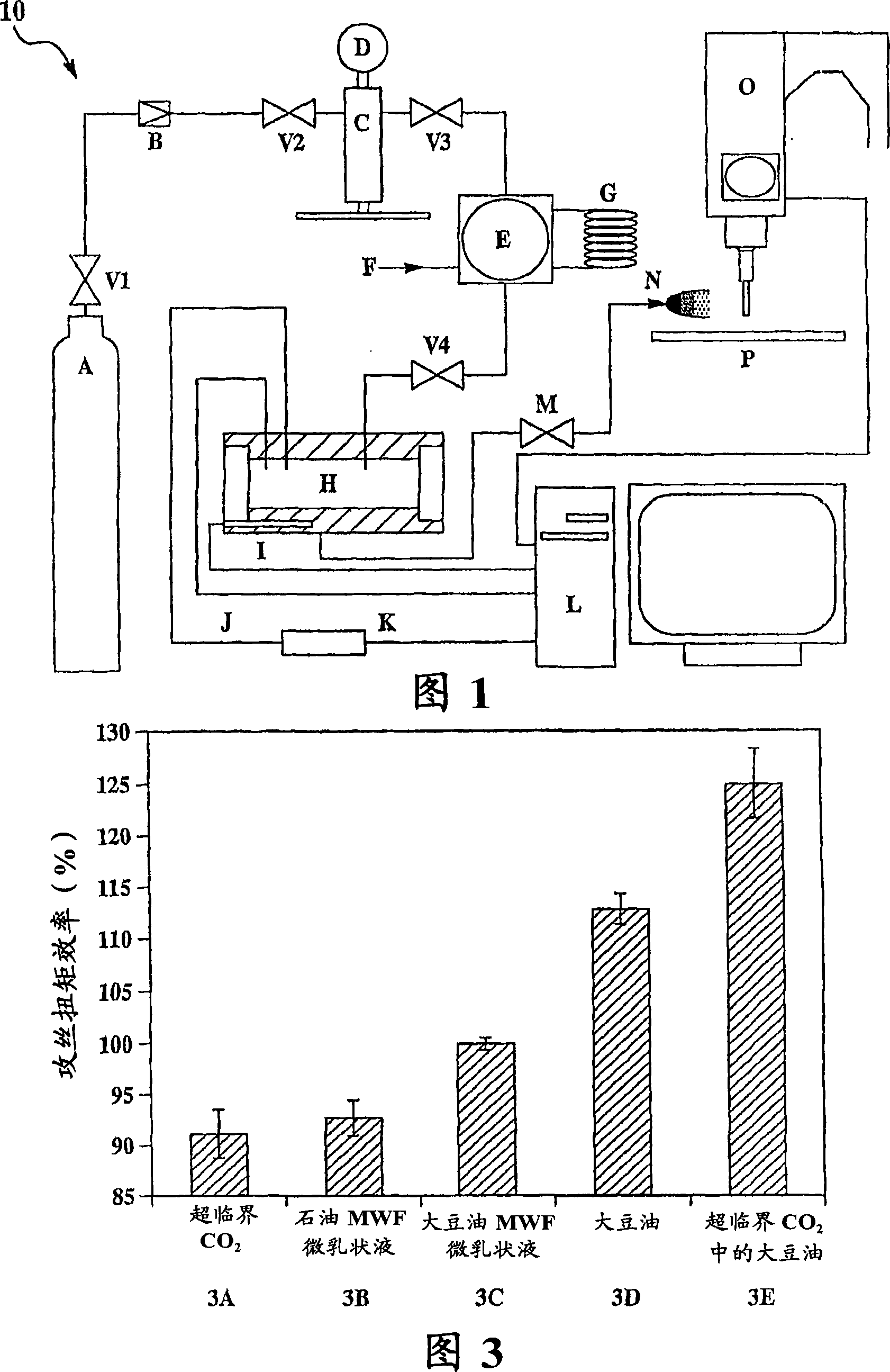

Method used

Image

Examples

Embodiment

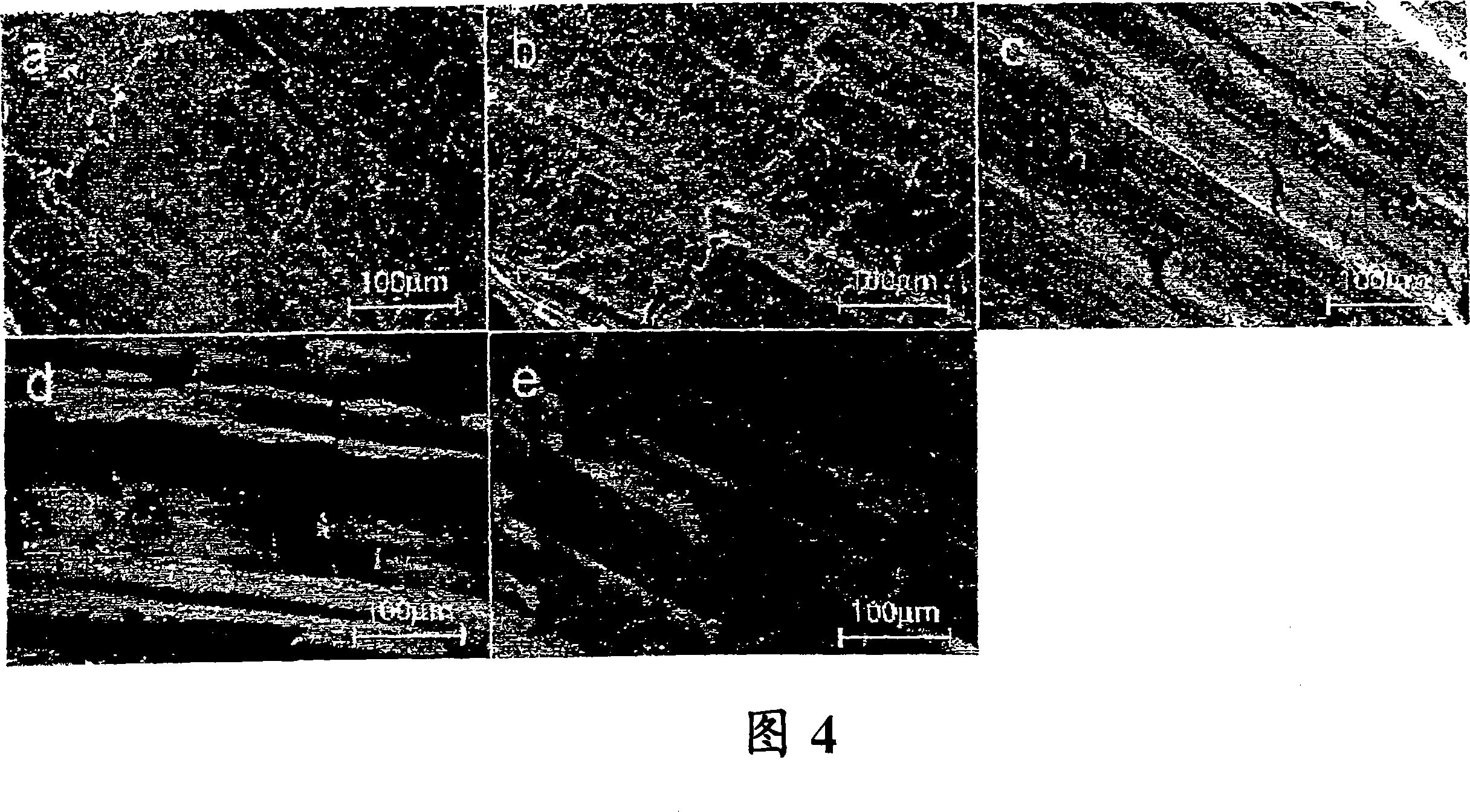

[0041] Tapping torque test method

[0042]The machinability of the MWF developed as disclosed herein was tested by tapping torque using a MicroTap Mega G8 (Rochester Hills, MI) machine tool at a machining speed of 1000 RPM in pre-drilled and pre-reamed 240M6 boreholes ( Maras Tool, Schaumburg, IL) on 1018 steel workpieces. Tapping was performed using an uncoated high speed steel (HSS) tap (for 1018 steel) with a 60° pitch and 3 straight flutes. MWF evaluation was performed according to ASTM D 5619 (the Standard for Comparing Metal Removal Fluid Using the Tapping Torque Test Machine), due to the use of The MWF evaluates the test bed, making several modifications to the standard. MWF performance is reported herein as % tapping torque efficiency (%), which is the average torque measured during full engagement of the tool, normalized to the measured average torque of the reference MWF. Higher efficiency indicates improved performance in the tapping torque test, and has been sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com