Metal processing and molding method for reducing plastic resilience

A metal processing and plasticity technology, applied in the field of processing and forming of metal sheets, can solve the problems of large required load, difficult processing, and difficult to meet the yield strength and springback of high-strength metal sheets, so as to achieve easy processing and forming, and strong promotion. Value, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

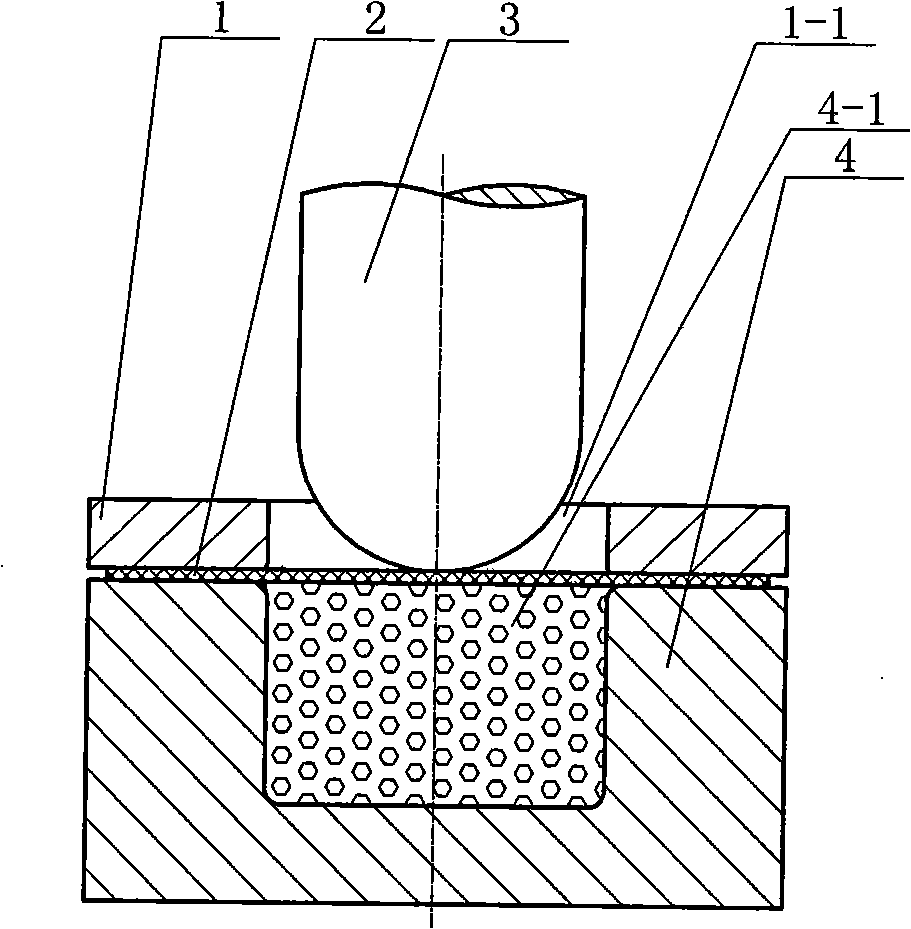

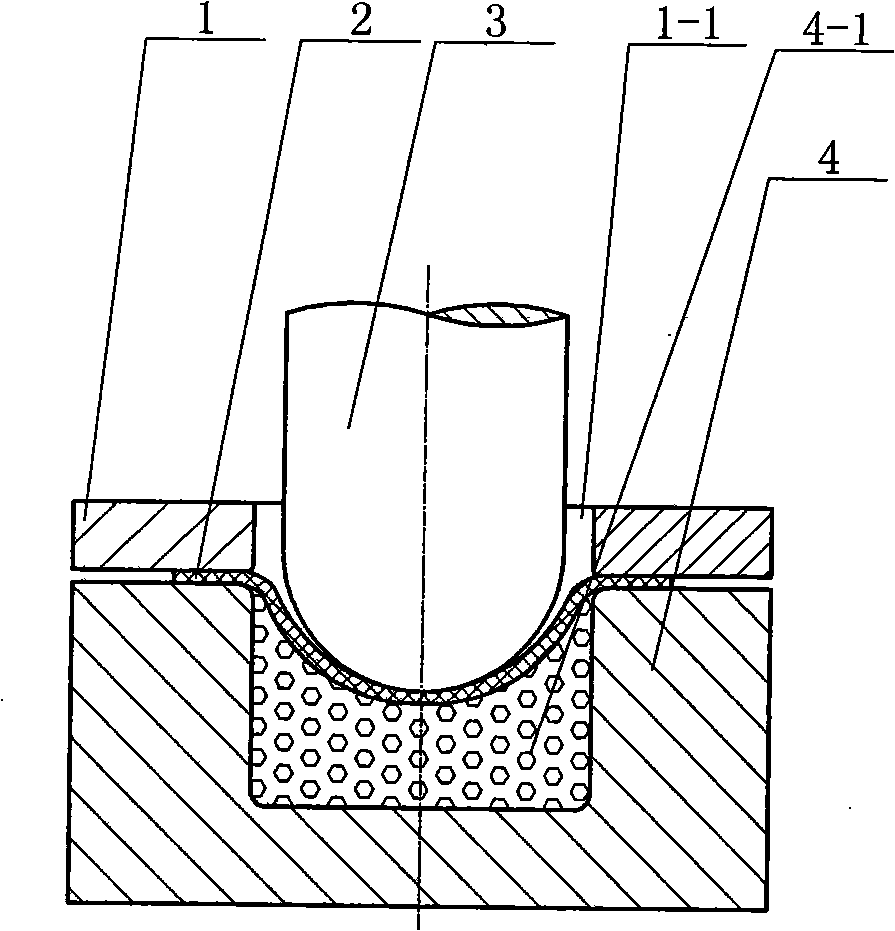

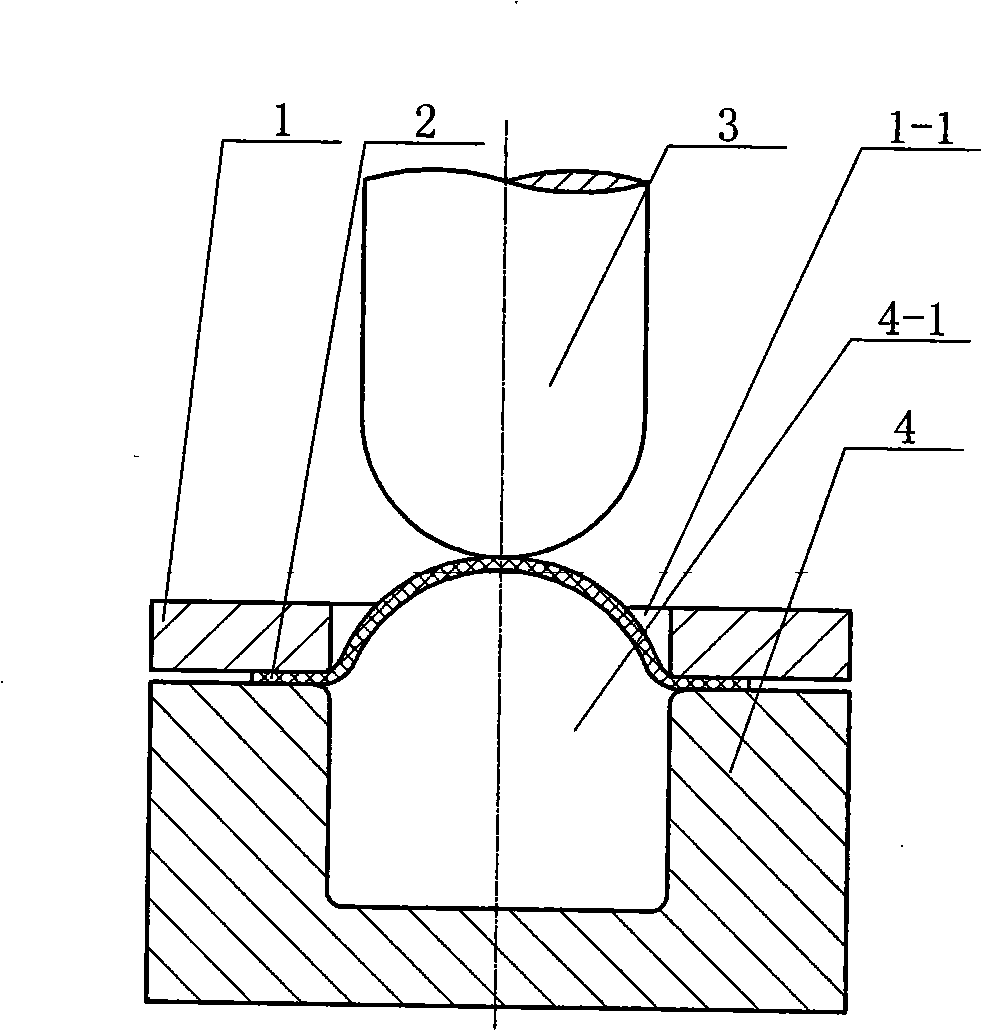

[0006] Specific implementation mode one: combine figure 1 - Fig. 5 illustrates this embodiment, and this embodiment is completed by the following steps: one, the sheet material 2 is placed on the die 4; The mold cavity 1-1 of the side ring 1 is coaxial with the concave mold cavity 4-1 of the die 4 and has the same aperture; 3. The punch 3 moves downward to apply pressure, and the sheet material 2 is deformed and flows into the concave mold cavity 4-1; 4. Remove the punch 3; 5. Remove the blank holder 1; 6. Place the sheet 2 on the die 4 in reverse; 7. Place the blank holder 1 on the sheet 2 and apply the blankholder Force, the mold cavity 1-1 of blank holder 1 is coaxial with the concave mold cavity 4-1 of die 4; Compared with the deformation in the original pre-strained direction, the elastic limit (yield limit) of the metal deformed in one direction is significantly lower when it is deformed in the opposite direction. This phenomenon is the Bauschinger effect of the metal. ...

specific Embodiment approach 2

[0007] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is: sand is provided in the concave mold 4 in step 1-step 5. First put a certain amount of sand in the concave mold cavity; place the blank on the concave mold; place the blank holder on the blank and apply blankholder force; the punch moves down to apply pressure, and the blank deforms and flows into the cavity. In the cavity of the concave mold; remove the punch and blank holder; pour out the sand in the cavity of the concave mold; place the sheet on the die in reverse; place the blank holder on the sheet and apply blankholder force ; The punch moves down to apply pressure, and the sheet deforms and flows into the cavity of the concave model. Due to the back pressure of the sand during the initial deep drawing, the thinning of the sheet metal during preforming is small, so the formed parts have good surface f...

specific Embodiment approach 3

[0008] Specific implementation mode three: In step one of this implementation mode, the sheet material 2 is superhard aluminum alloy or titanium alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com