Rapid roadbed construction process

A construction technology and road bed technology, applied in roads, roads, buildings, etc., can solve the problems of low construction efficiency, easy formation of ruts, and long construction period, so as to improve construction efficiency, facilitate the mixing of aggregates, and improve construction efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

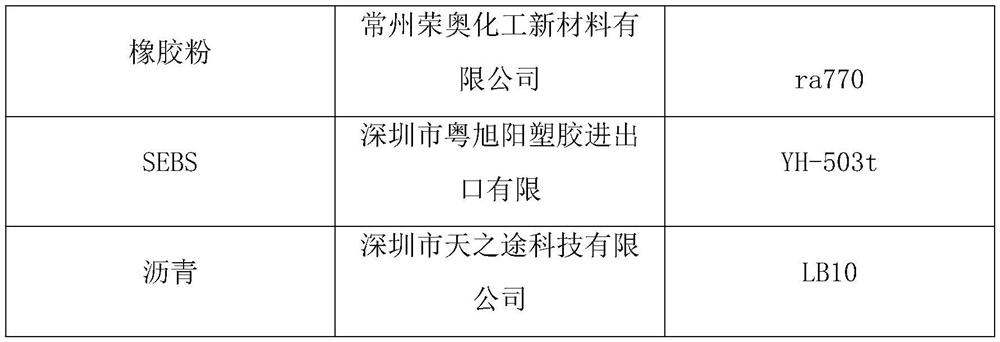

[0059] A kind of preparation of modified SEBS, comprises the steps:

[0060] Step 1: Weigh 20g of SEBS and 200g of carbon tetrachloride, put them into a 500mL three-necked bottle with a heating jacket, and stir with a high-speed mixer to completely dissolve SEBS to obtain mixture A;

[0061] Step 2: Weigh 1 g of sodium sulfite, add it into the mixture A obtained in step 1, stir evenly to dissolve the sodium sulfite, heat to 40°C, and react at constant temperature for 5 hours to prepare mixture B;

[0062] Step 3: Weigh 2 g of concentrated sulfuric acid with a mass fraction of 75%, add it to the mixture B prepared in step 2, heat to 75° C., and react for 12 hours to prepare mixture C;

[0063] Step 4: Weigh 3g of methacrylic acid, add it to the mixture C prepared in step 3, stir evenly, react for 1h, cool to normal temperature, and recover carbon tetrachloride, filter, and use 75% mass fraction of Rinse with ethanol solution, then rinse with deionized water, put into an oven a...

preparation example 2

[0065] A kind of preparation of modified SEBS, comprises the steps:

[0066] Step 1: Weigh 15g of SEBS and 150g of carbon tetrachloride, put them into a 500mL three-necked bottle with a heating jacket, and stir with a high-speed mixer to completely dissolve SEBS to obtain mixture A;

[0067] Step 2: Weigh 0.75 g of sodium sulfite, add it into the mixture A obtained in step 1, stir evenly to dissolve the sodium sulfite, heat to 40°C, and react at constant temperature for 4 hours to prepare mixture B;

[0068] Step 3: Weigh 1.5 g of concentrated sulfuric acid with a mass fraction of 72%, add it to the mixture B prepared in step 2, heat to 60° C., and react for 10 hours to prepare mixture C;

[0069] Step 4: Weigh 2.5g of methacrylic acid, add it to the mixture C prepared in Step 3, stir evenly, react for 50min, cool to normal temperature, and recover carbon tetrachloride, filter, and use a mass fraction of 73% Rinse with ethanol solution, and then rinse with deionized water, pu...

preparation example 4

[0078] A kind of modified asphalt is prepared through the following steps:

[0079] Step 1: Weigh 85g of asphalt and 5g of modified SEBS, put them into a 500mL three-neck bottle with a heating jacket, stir with a high-speed mixer, and heat to 190°C to dissolve the asphalt and modified SEBS to prepare mixture Ⅰ ,spare:

[0080] Step 2: Weigh 10g of rubber powder, add it to the mixture I in step 1, and stir until the rubber powder is evenly mixed to obtain mixture II, which is set aside;

[0081] Step 3: Weigh 2 g of bis-2-5, add it to the mixture II obtained in step 2, stir until the bis-2-5 is dissolved, and react for 8 hours to prepare the mixture III;

[0082] Step 4: Weigh 3g of calcium carbonate, 1g of bis(2-ethylhexyl) phthalate, 2g of magnesium aluminum silicate and 3g of ethyl cellulose, and add them to the mixture III prepared in step 3 , stir to dissolve calcium carbonate, bis(2-ethylhexyl) phthalate, magnesium aluminum silicate and ethyl cellulose, react for 2 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com