Glass for chemical strengthening, and chemically strengthened glass

A technology of strengthening glass and glass transition, applied in glass production and other directions, can solve problems such as reducing precision and achieve the effect of high surface compressive stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

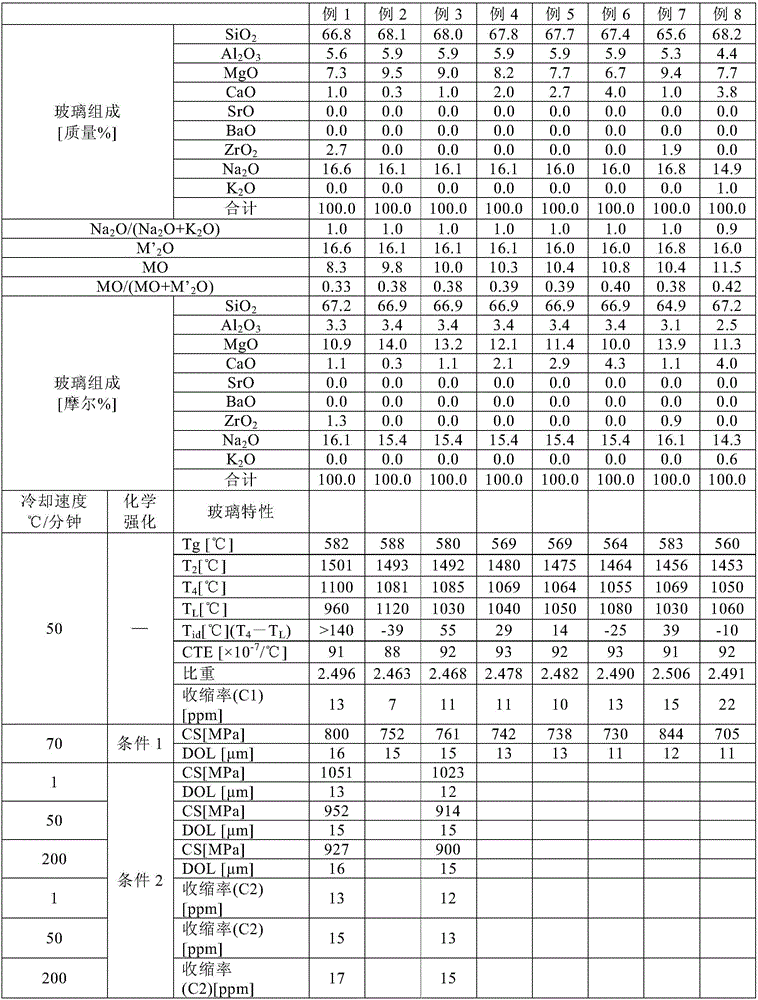

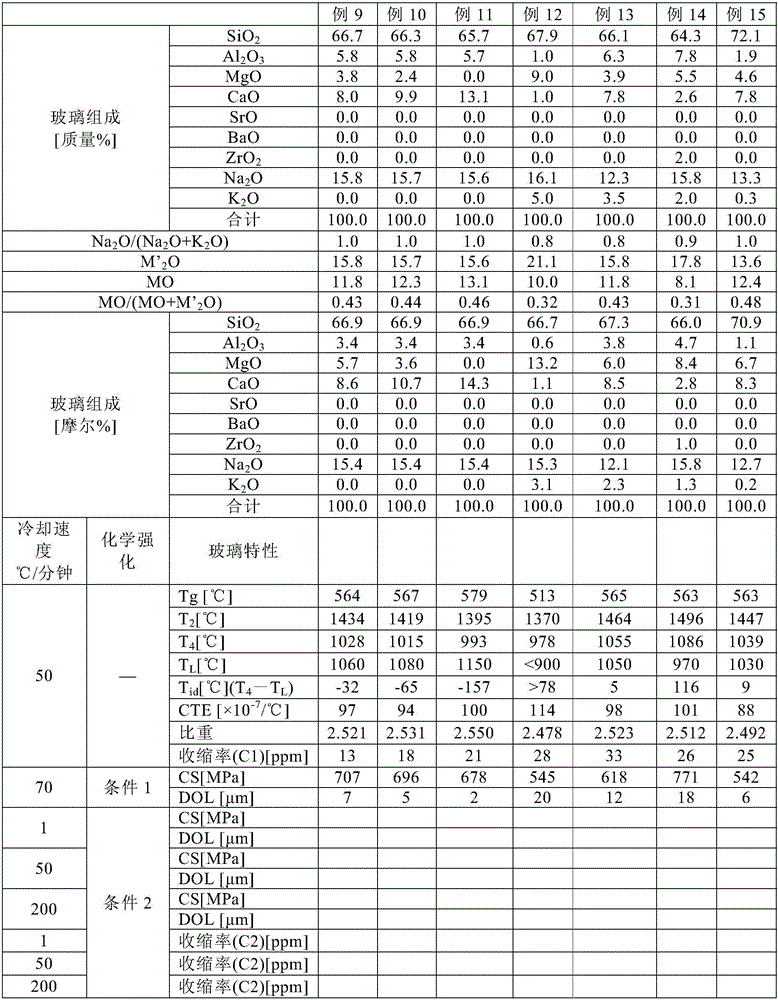

[0181] Hereinafter, the present invention will be specifically described with reference to examples, but the present invention is not limited to these examples. In addition, examples 1-8 are examples, and examples 9-15 are comparative examples.

example 1~15

[0183] (Production of glass for chemical strengthening)

[0184] Raw materials for each component of glass for chemical strengthening were prepared so as to have the compositions shown in Table 1 and Table 2 (expressed in mass percent and mole percent based on oxides). With respect to 100 mass parts of the raw material components for glass, SO was added to the raw material for glass 3 The sulfate was converted to 0.1 parts by mass and melted by heating at a temperature of 1600° C. for 3 hours using a platinum crucible. During melting, a platinum stirrer was inserted and stirred for 1 hour to homogenize the glass. Next, the molten glass was flowed out, kept at Tg+50° C. for 1 hour, and then cooled at 1° C. / min. After cooling, grinding and polishing were performed to form a plate, and as the glass for chemical strengthening of Examples 1 to 15, a plurality of glass plates for physical property measurement and glass plates for chemical strengthening were obtained in each exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com