Vacuum magnetron sputtering coating production line system of continuous solar energy collector chip

A technology of solar collector plate and coating production line, which is applied in sputtering coating, vacuum evaporation coating, ion implantation coating and other directions, can solve the secondary pollution of the film layer, affect the heat collection efficiency of the collector plate core, and destroy the film layer performance and other issues, to achieve the effect of improving weather resistance, strong market competitiveness and vitality, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

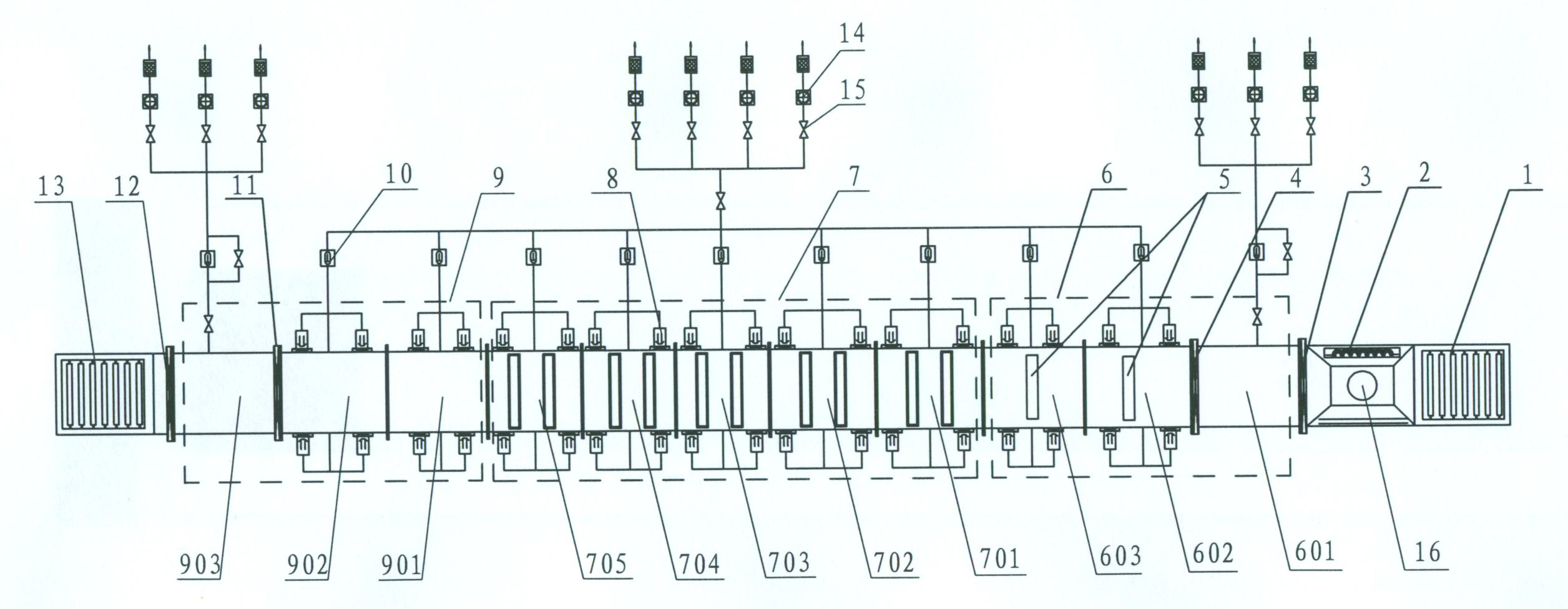

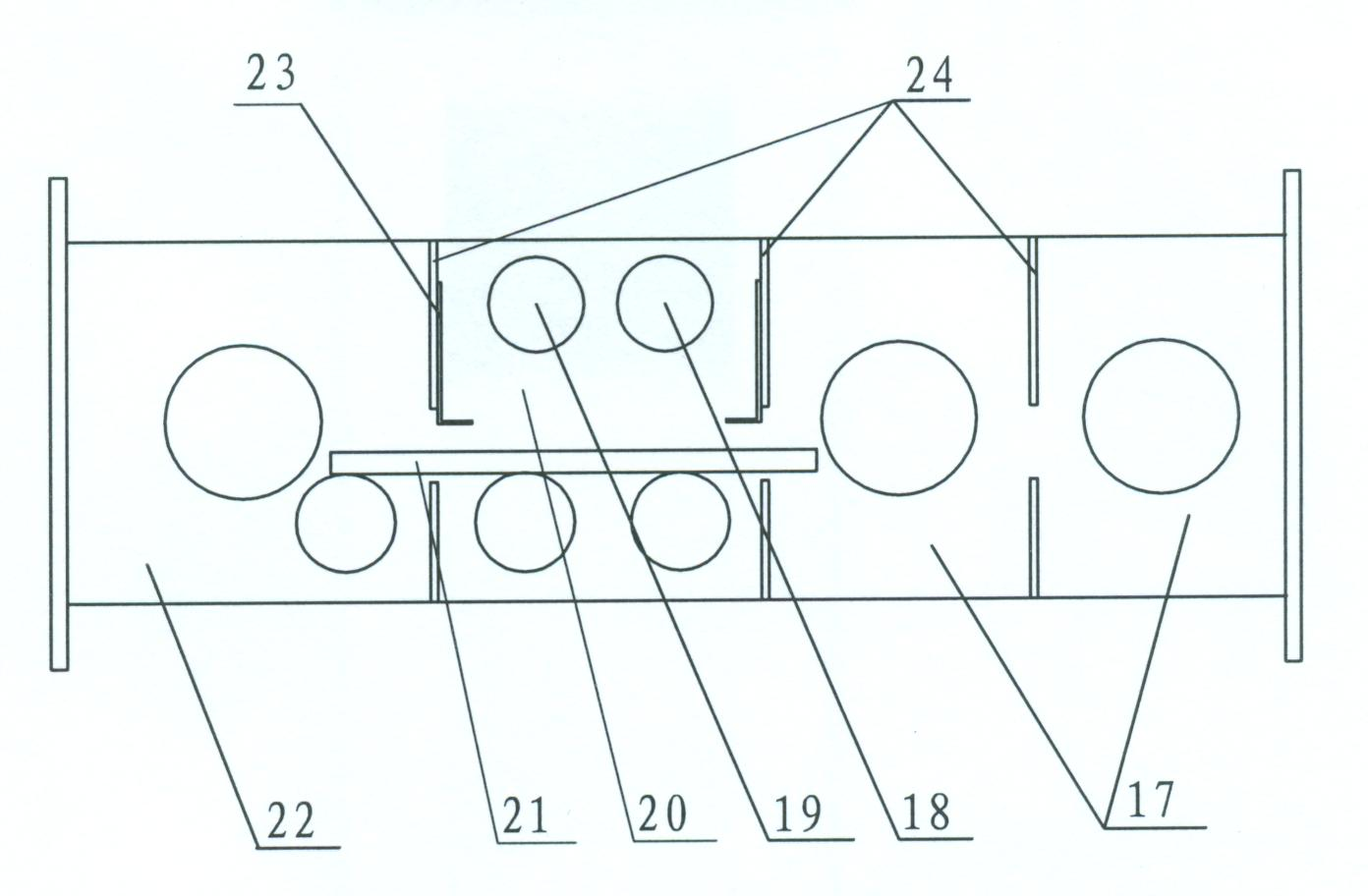

[0024] Such as figure 1 As shown, the main structure of the present invention includes a coating line system, which is a film-loading table 1, a dust-proof heating chamber 16 provided with a high-efficiency heater and a temperature control device 2, a film-in area 6, a film-coating area 7, a film-out area 9, a lower The film table 13, the evacuation system and the transmission mechanism running through the entire production line system, the film feeding area 6 includes a film feeding chamber 601, a film feeding transition chamber 602 and a film feeding buffer room 603, and the coating area 7 includes a deposition of high reflectivity metal layer coating Chamber 701, depositing different absorbing layer coating chambers 702 and 703 with different metal contents, depositing anti-reflection layer coating chamber 704 and depositing protective layer coating chamber 705, film output area 9 includes film output buffer chamber 901, film output transition chamber 902 and film output In...

example 2

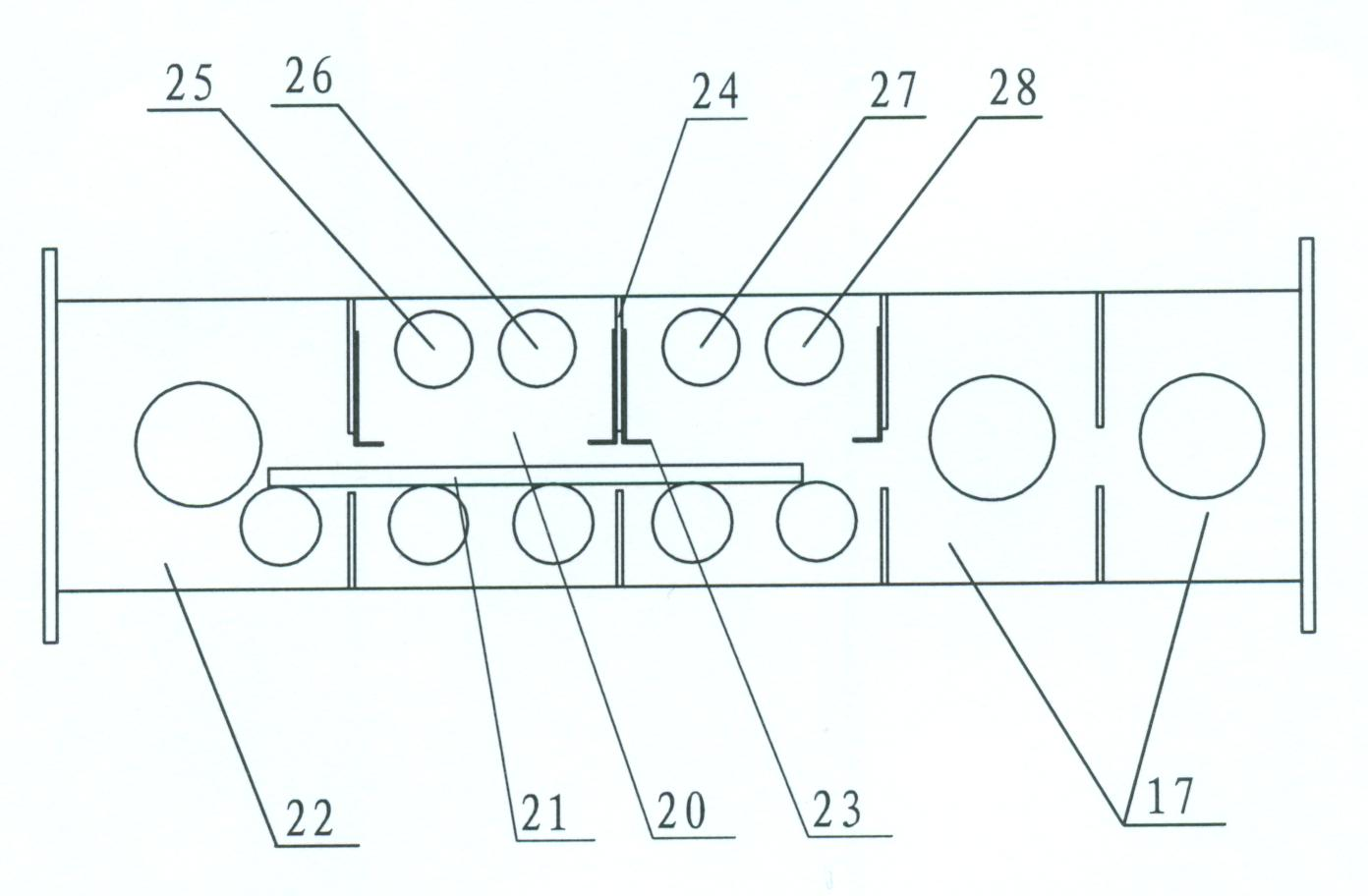

[0030] Such as Figure 4 As shown, the main structure of the present invention includes a loading table 1, a dust-proof heating chamber 16 provided with a high-efficiency heater and a temperature control device 2, an entry and exit area 31, a coating area 32, an unloading table 13, an evacuation system and a through-hole The transmission mechanism of the production line system, the entry and exit area includes the entry and exit film chamber 3101, the entry and exit transition chamber 3102 and the entry and exit buffer chamber 3103, and the coating area includes the deposition protective layer coating chamber 3201, the deposition of high reflectivity metal layer and anti-reflection layer coating Chamber 3202 and absorption layer coating chamber 3203 with different deposited metal content; loading table 1, dustproof heating chamber 16, unloading table 13, film in and out chamber 3101, film in and out transition chamber 3102, film in and out buffer room 3103, depositing protectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com