Insulating coating and processing technology thereof

A technology of insulating coatings and solvents, which is applied in the direction of fireproof coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems affecting wave transmission performance, operation accidents, and insulation level decline, etc., to improve waterproof and moisture-proof performance, and strong resistance to damage Performance, airtightness improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

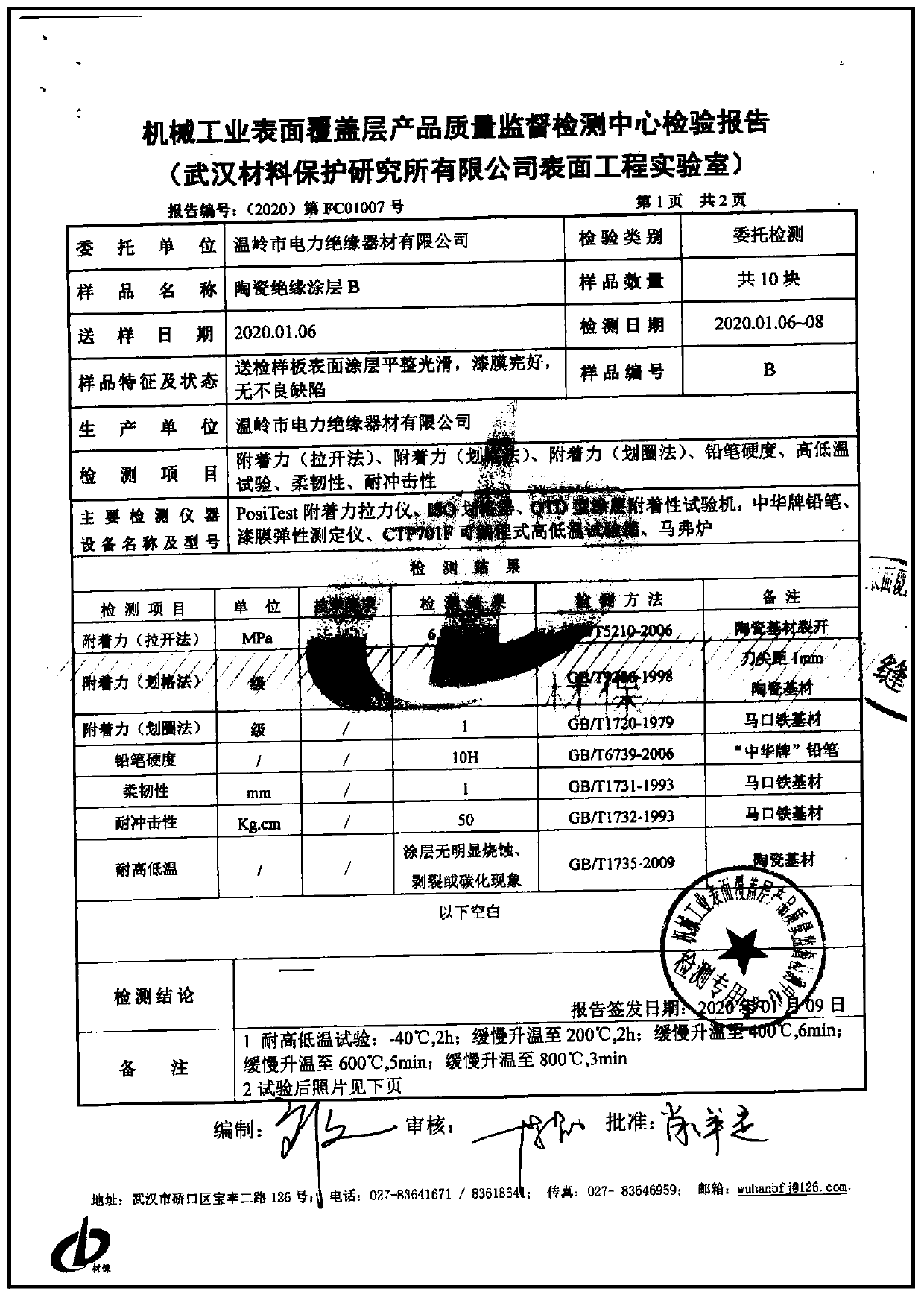

[0030] The insulating coating includes the following materials in parts by mass: 90 parts of organic silicon powder solid resin, 75 parts of combined solvent, 8 parts of thermoplastic elastomer, 3 parts of fluorosurfactant, 50 parts of ultrafine mica powder, 2 parts of nano silicon dioxide Parts, 3 parts of hydrocarbon-based silicone oil, wherein, the combined solvent is used to dissolve the organic silicon powdery solid resin. The combined solvent is composed of at least two materials in parts by mass: 30-50 parts of toluene, 30-50 parts of acetone and 30-50 parts of isopropanol. That is, the combined solvent can be composed of toluene and acetone or toluene and isopropanol or acetone and isopropanol or toluene, acetone and isopropanol, and preferably the two or three materials that make up the combined solvent are evenly matched. The thermoplastic elastomer is SEBS. Naturally, the thermoplastic elastomer can also be TPU or TPV. In this embodiment, the preferred combined so...

Embodiment 2

[0041] The insulating coating includes the following materials in parts by mass: 100 parts of organic silicon powder solid resin, 100 parts of combined solvent, 10 parts of thermoplastic elastomer, 5 parts of fluorosurfactant, 60 parts of ultrafine mica powder, and 5 parts of nano-silica Parts, 5 parts of hydrocarbon-based silicone oil, wherein, the combined solvent is used to dissolve the organic silicon powdery solid resin. The combined solvent is composed of at least two materials in parts by mass: 30-50 parts of toluene, 30-50 parts of acetone and 30-50 parts of isopropanol. That is, the combined solvent can be composed of toluene and acetone or toluene and isopropanol or acetone and isopropanol or toluene, acetone and isopropanol, and preferably the two or three materials that make up the combined solvent are evenly matched. The thermoplastic elastomer is SEBS. Naturally, the thermoplastic elastomer can also be TPU or TPV. In this example, the combined solvent consisted...

Embodiment 3

[0051] The insulating coating includes the following materials in parts by mass: 105 parts of organic silicon powder solid resin, 130 parts of combined solvent, 11 parts of thermoplastic elastomer, 6 parts of fluorosurfactant, 70 parts of ultrafine mica powder, and 6 parts of nano-silica Parts, 6 parts of hydrocarbon-based silicone oil, wherein, the combined solvent is used to dissolve the organic silicon powdery solid resin. The combined solvent is composed of the following three materials in parts by mass: 30-50 parts of toluene, 30-50 parts of acetone, and 30-50 parts of isopropanol. The thermoplastic elastomer is SEBS. Naturally, the thermoplastic elastomer can also be TPU or TPV. In this example, the combined solvent is acetone and isopropanol.

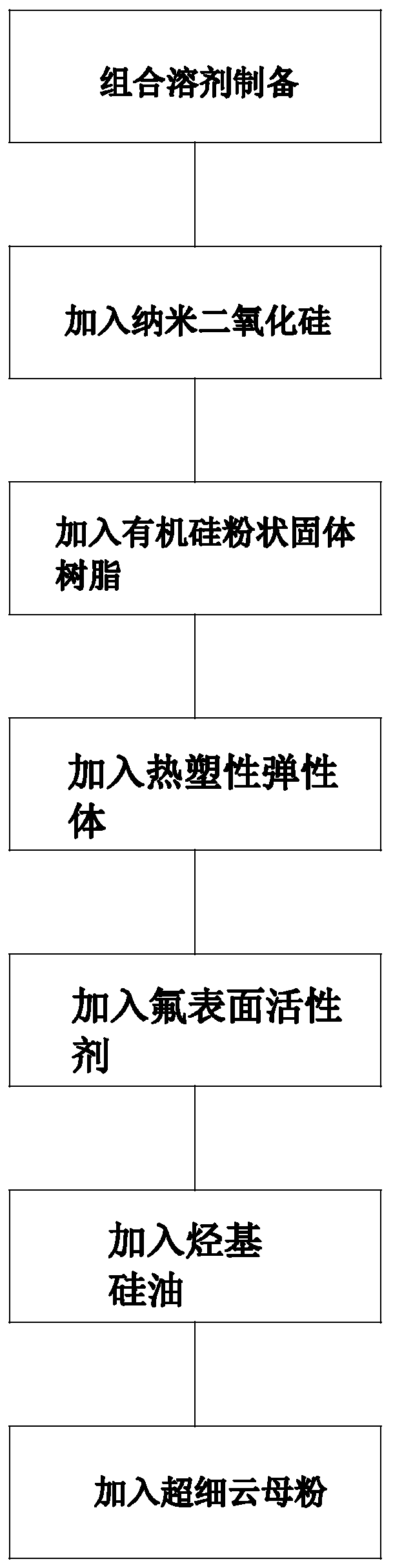

[0052] The processing technology of insulating coating includes the following steps:

[0053] A, preparation of combined solvent: use at least two materials among the three materials of toluene, acetone and isopropanol to mix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com