Waste PVC (Polyvinyl Chloride) and fly ash composite material and preparation method thereof

A technology of composite materials and fly ash, which is applied in the field of waste PVC and fly ash composite materials and their preparation, can solve the problems of large amount of fly ash, no patent report, poor material performance, etc., to improve impact performance, test The effect of improving processing performance over a long period of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

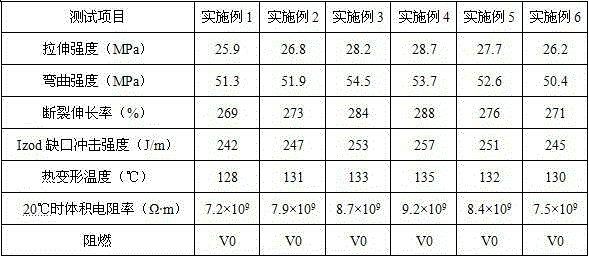

Examples

Embodiment 1

[0051] The dust adhering to the surface of waste PVC containing 50% by weight of PVC is removed, crushed, and then passed through a 120 mesh sieve for use. The waste PVC is the waste PVC wire and cable of recovery; Dry at 110°C for 3 hours, pass through a 120-mesh sieve, and set aside; weigh 80Kg of waste PVC, 35Kg of fly ash, 3Kg of dioctyl terephthalate, 0.4Kg of antimony trioxide, and 0.6Kg of aluminum hydroxide. Calcium-zinc composite stabilizer 0.5Kg, chlorine content is 25% chlorinated polyethylene 0.5Kg, stearic acid 0.1Kg, polyethylene wax 0.2Kg, tetrakis[β-(3,5-di-tert-butyl-4- Hydroxyphenyl) propionic acid] pentaerythritol ester 0.1Kg mixed; put the mixed raw materials into a high-speed blender, and stir for 25min at a temperature of 100°C; extrude and granulate the stirred raw materials through a twin-screw extruder, After material cutting and air cooling, waste PVC and fly ash composite materials are obtained; the screw temperature of the twin-screw extruder is: 13...

Embodiment 2

[0053] The dust adhering to the surface of waste PVC containing 53% by weight of PVC is removed, crushed, and then passed through a 120 mesh sieve for use. The waste PVC is the waste PVC film of recovery; Dry at ℃ for 2 hours, pass through a 120-mesh sieve, and set aside; Weigh 90Kg of waste PVC, 40Kg of fly ash, 3Kg of trioctyl trimellitate, 1Kg of epoxy soybean oil, 0.5Kg of antimony trioxide, hydrogen Aluminum oxide 0.7Kg, calcium-zinc composite stabilizer 0.8Kg, chlorinated polyethylene 0.8Kg with a chlorine content of 30%, polyethylene wax 0.4Kg, tris[2.4-di-tert-butylphenyl] phosphite 0.2Kg mixed Put the mixed raw materials into a high-speed blender and stir for 15 minutes at a temperature of 140°C; extrude the stirred raw materials through a twin-screw extruder to make granules, cut materials, and air-cool to obtain waste PVC and Fly ash composite material; the screw temperature of the twin-screw extruder is: 140°C for the first stage, 140°C for the second stage, 135°C ...

Embodiment 3

[0055] The dust adhering to the waste and old PVC surface that will contain 56% weight PVC is removed, broken, then cross 120 mesh sieves, stand-by, and described waste and old PVC is the waste and old PVC hose that reclaims; Particle diameter is the fly ash of 0.06mm Dry at 120°C for 1 hour, pass through a 120-mesh sieve, and set aside; weigh 100Kg of waste PVC, 45Kg of fly ash, 3Kg of dioctyl terephthalate, 2Kg of trioctyl trimellitate, and epoxy soybean oil 1Kg, 0.6Kg of antimony trioxide, 08Kg of aluminum hydroxide, 1.1Kg of calcium-zinc composite stabilizer, 1.1Kg of chlorinated polyethylene with a chlorine content of 35%, 0.3Kg of stearic acid, 0.3Kg of polyethylene wax, β- (3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate 0.3Kg mixed; put the mixed raw materials into a high-speed blender, and stir at a temperature of 120°C for 20min; The stirred raw materials are extruded and granulated by a twin-screw extruder, and are cut and air-cooled to obtain a composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com