Free door controller

A free, door frame technology, applied to switches with brakes, door/window accessories, wing openers, etc., can solve the problems of difficult operation, complicated installation procedures, time-consuming and laborious maintenance, etc. Wide range of uses and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

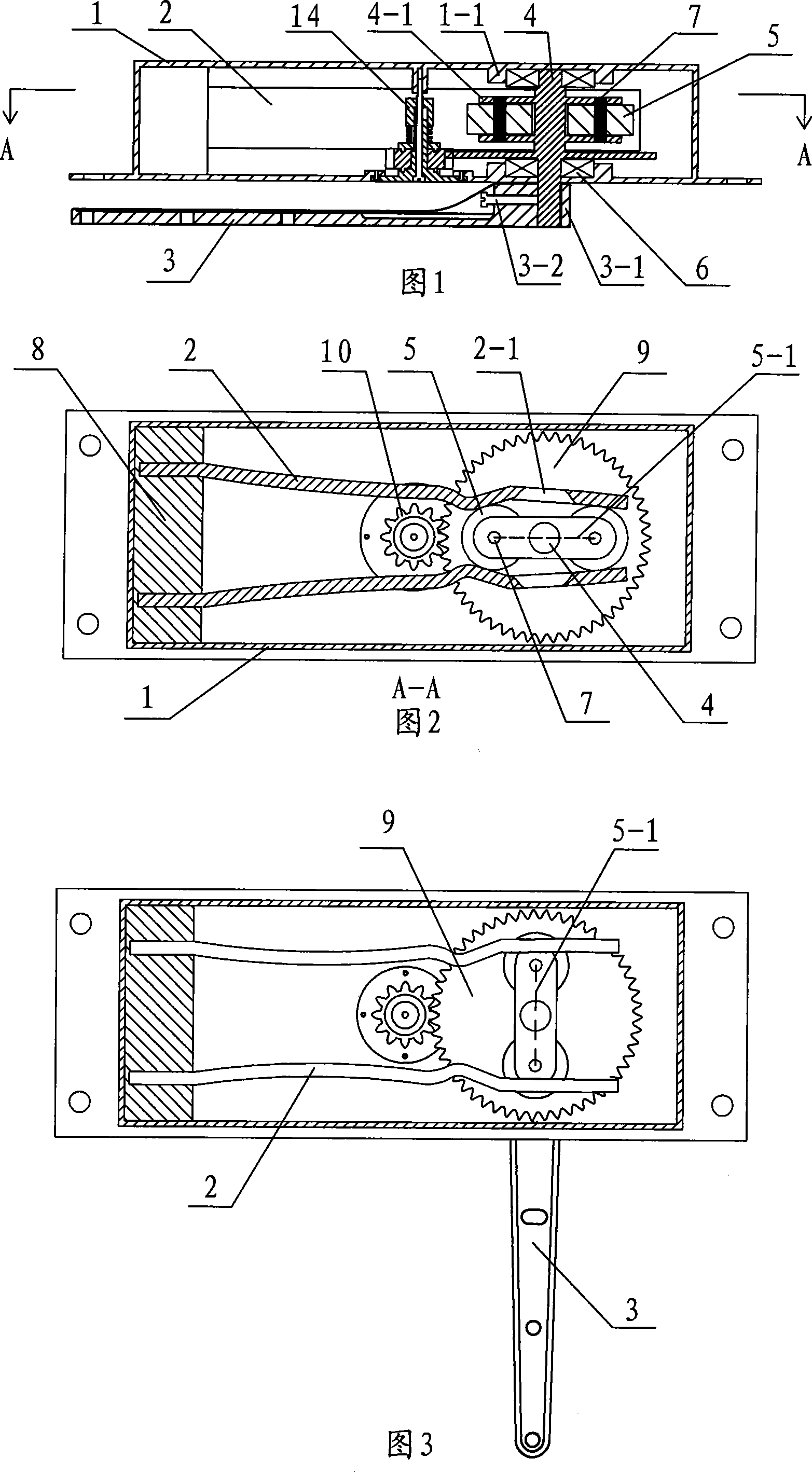

[0044] Refer to Figure 1, Figure 2, Figure 3, Figure 4 and Figure 5 for the embodiment of the upper shaft rotation control device of the free door. A free door upper shaft rotation control device includes a housing 1, a speed regulating damping device, an elastic splint 2, Rotate the connecting arm 3, rotate the upper shaft 4 and at least two rollers 5; the rollers are symmetrically installed on both sides of the rotating upper shaft with the rotating upper shaft as the center; the rotating upper shaft is rotated and fixed between the upper and lower side plates in the housing, One end of the rotating upper shaft extends out of the lower side plate of the housing; one end of the rotating connecting arm is fixed on the end of the rotating upper shaft protruding from the housing, and the center line of the two rollers is parallel to the rotating connecting arm; One end of the elastic splint is fixed, the other end of the elastic splint clamps the roller, and the speed regulating ...

Embodiment 2

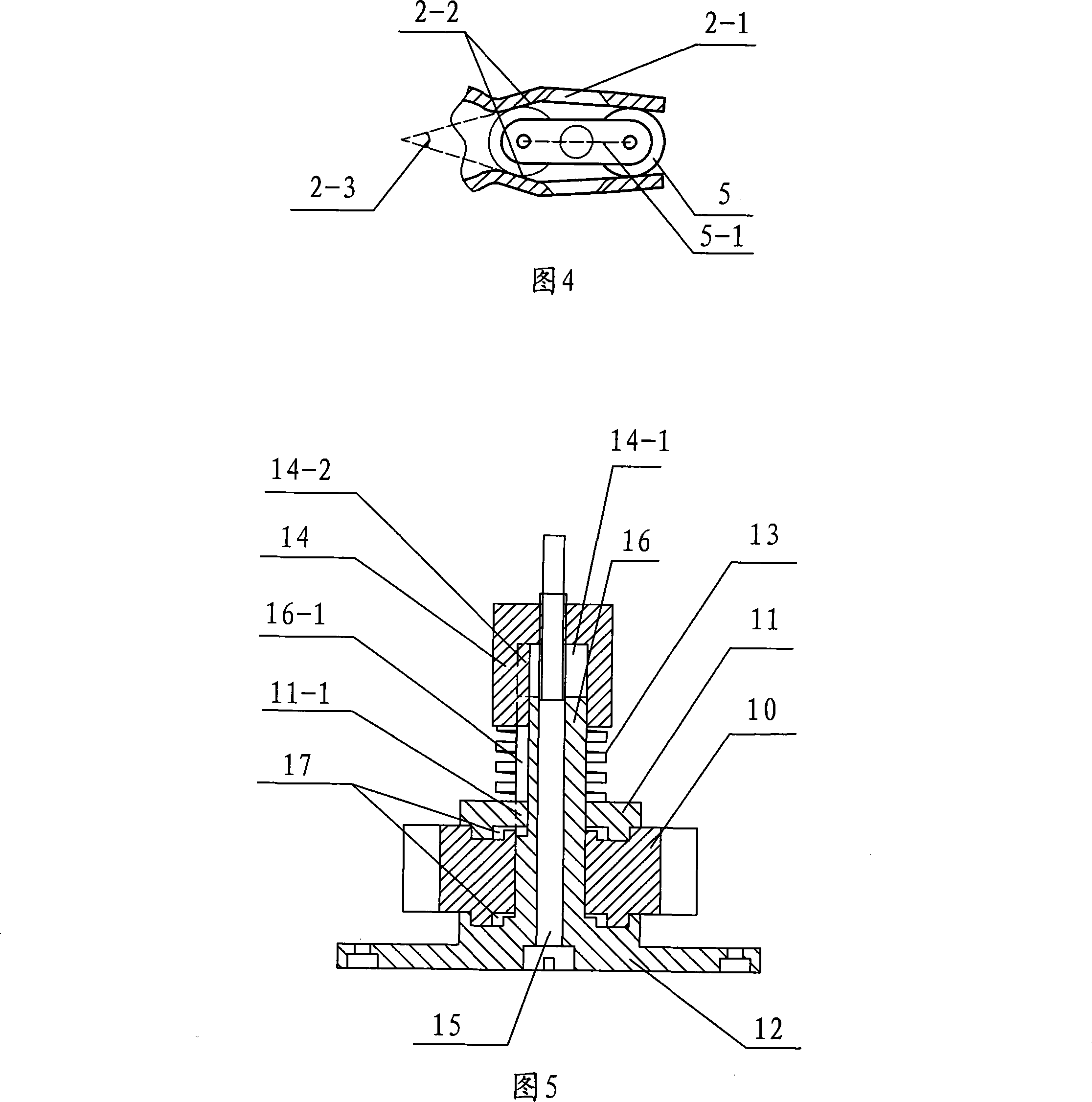

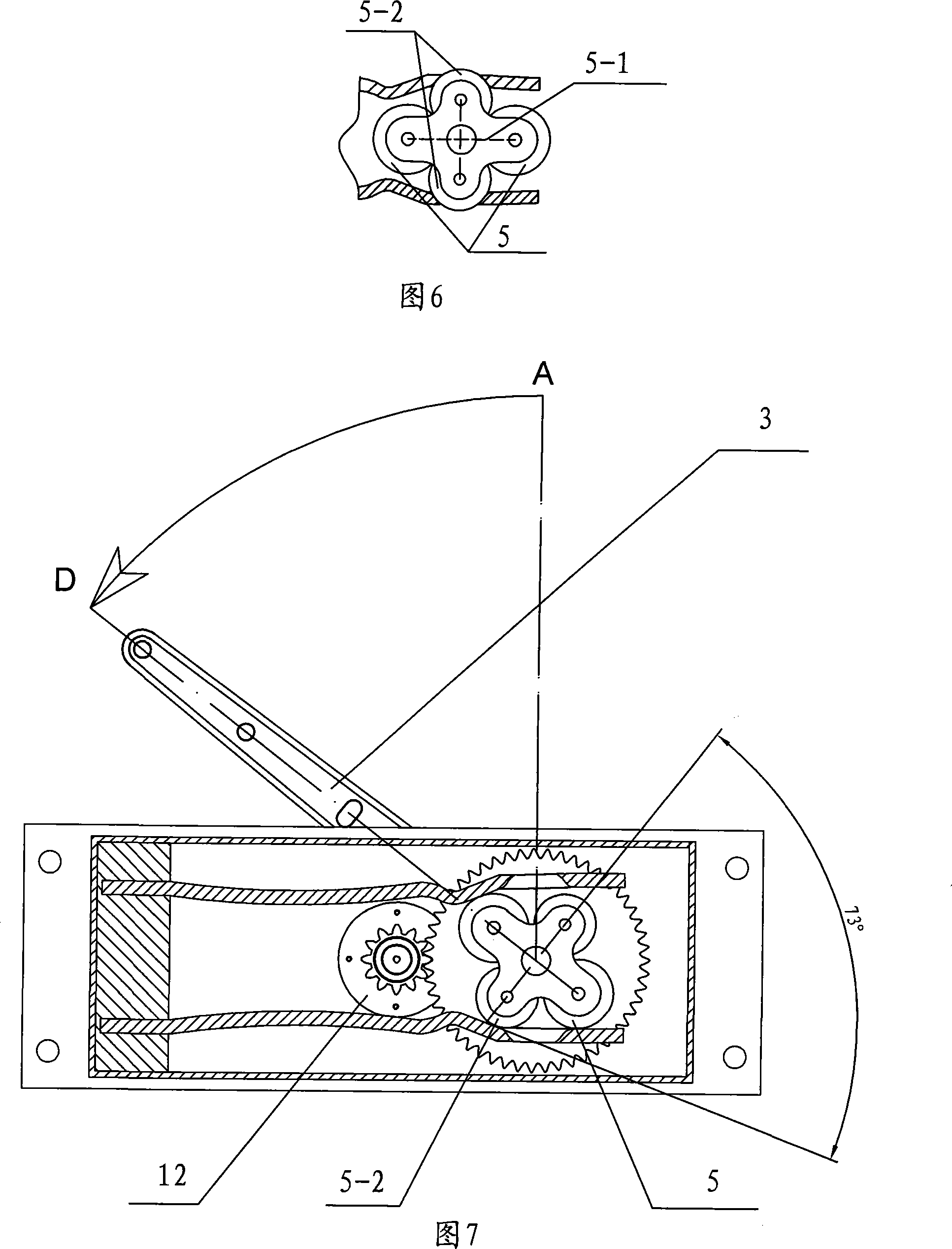

[0054] Referring to Figure 6, Figure 7 and Embodiment 1, in order to improve the stability of the door in the closed state and improve the wind resistance of the door when there is wind, two auxiliary rollers are added on the basis of Embodiment 1, that is, the free door There are four rollers in the upper shaft rotation control device. The diameters of the four rollers can be the same or different. The two rollers are divided into the first group and the second group. The two rollers of the first group are used to rotate the upper shaft. The two rollers of the second group are auxiliary rollers, which are symmetrically installed on the rollers of the first group. The two sides of the center connecting line, and the center distance of the two rollers of the second group is smaller than the center distance of the two rollers of the first group; Figure 6 shows the relationship between the elastic splint and the rollers when the upper shaft control device of the free door is in th...

Embodiment 3

[0056] Referring to Fig. 8, Fig. 9, 10 and Embodiment 1, the difference from Embodiment 1 is that the elastic splint is two rigid splints 18 and extension springs 19; one end of the two rigid splints is rotated and fixed by the splint shaft 20 in the housing , the splint shaft is fixed at one end of the housing through the fixed block 21 and the splint shaft bearing 22; the other ends of the two rigid splints clamp the two rollers of the rotation; the tension spring is arranged between the two rigid splints to pull the two rigid splints , the extension springs are arranged at the front and rear ends of the rollers clamped by the two rigid splints at the same time, and one or more can be arranged respectively according to the needs.

[0057] Fig. 8 and Fig. 9 show that when the door leaf of this embodiment is in the closed state, one end side of the two rigid splints clamps the two rollers at the same time through the action of the tension spring, and the center connection line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com