High-strength soluble aluminum alloy and preparation method and application thereof

An aluminum alloy, high-strength technology, applied in the field of powder metallurgy, can solve the problems of uneven material dissolution process, complex preparation process, coarse grains of cast aluminum alloy, etc., and achieve the effect of stable and reliable preparation method and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

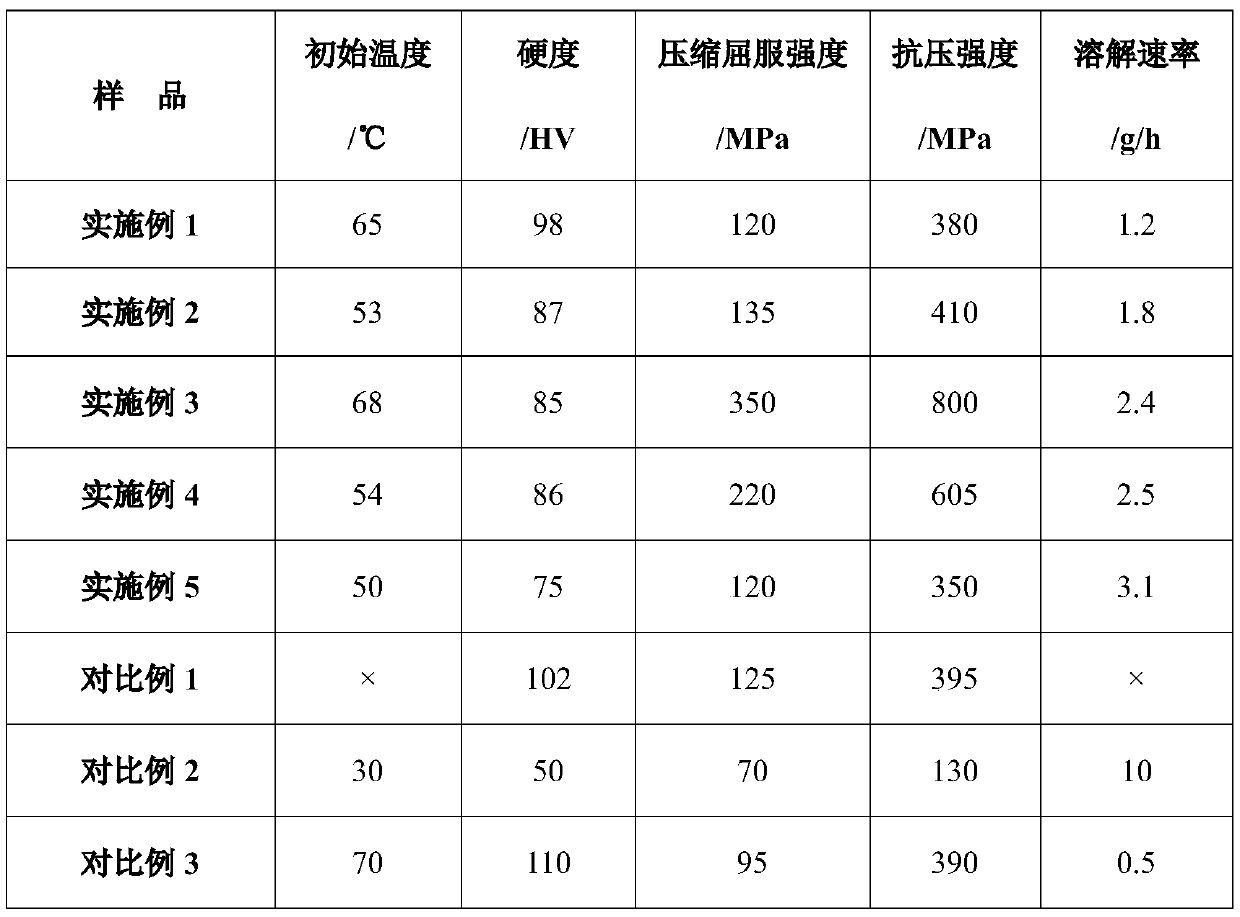

Embodiment 1

[0032] A high-strength soluble aluminum alloy, prepared by powder metallurgy from the following raw materials in mass percentage: Al92.5%, Ga1.5%, In0.5%, Sn0.5%, Cu0.8%, Mg4%, Ti0.2% . The particle size of each of the metal powders is 45 μm, and the Ga is solid.

[0033] A method for preparing a high-strength soluble aluminum alloy, comprising the following steps:

[0034] 1) Weigh the metal powder with a particle size of 45 μm according to the above-mentioned component distribution ratio, wherein the metal Ga is heated and melted, weighed 1% liquid paraffin and 0.6% polyethylene glycol, and fully mixed for 6 hours.

[0035] 2) Weigh a certain amount of uniformly mixed metal powder and put it into a rigid mold for compression molding with a pressure of 300 MPa.

[0036] 3) Put the pressed sample into a nitrogen atmosphere protection furnace for sintering, the heating rate is 2°C / min to the sintering temperature of 600°C, the holding time is 2h, and it is cooled with the fur...

Embodiment 2

[0038] A high-strength soluble aluminum alloy, prepared by powder metallurgy from the following raw materials in mass percentage: Al90.2%, Ga1.75%, In0.75%, Sn0.8%, Cu1%, Mg5%, Ti0.5% . The particle size of each of the metal powders is 150 μm, and the Ga is solid.

[0039]A method for preparing a high-strength soluble aluminum alloy, comprising the following steps:

[0040] 1) Weigh the metal powder with a particle size of 150 μm according to the above-mentioned component distribution ratio, wherein the metal Ga is heated and melted, and 0.5% polyethylene glycol and 0.75% ethylene bisstearamide are weighed and fully mixed for 4 hours.

[0041] 2) Weigh a certain amount of powder and put it into a rigid mold for compression molding with a pressure of 250 MPa.

[0042] 3) Put the pressed sample into a nitrogen atmosphere protection furnace for sintering, the heating rate is 4°C / min to the sintering temperature of 550°C, the holding time is 1h, and it is cooled with the furnace...

Embodiment 3

[0044] A high-strength soluble aluminum alloy is prepared by powder metallurgy from the following raw materials in mass percentage: Al75%, Ga3.8%, In1.5%, Sn0.7%, Cu0.5%, Mg7%. The particle size of each of the metal powders is 90 μm, and the Ga is solid.

[0045] A method for preparing a high-strength soluble aluminum alloy, comprising the following steps:

[0046] 1) The metal powder with a particle size of 90 μm is weighed according to the above-mentioned component distribution ratio, wherein the metal Ga is heated and melted, 1.5% liquid paraffin and 0.6% polyethylene glycol are weighed, and the mixture is fully mixed for 2 hours.

[0047] 2) Weigh a certain amount of uniformly mixed metal powder and put it into a rigid mold for compression molding with a pressure of 500 MPa.

[0048] 3) Put the pressed sample into a nitrogen atmosphere protective furnace for sintering, the heating rate is 6°C / min to the sintering temperature of 590°C, the holding time is 2h, and it is coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com