Triggered soluble blind plate for drilling

A triggering, drilling technology, applied in earth-moving drilling, wellbore/well components, sealing/packing, etc., can solve problems such as stuck drilling, long operation time, blowout, etc., and achieve the effect of improved reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

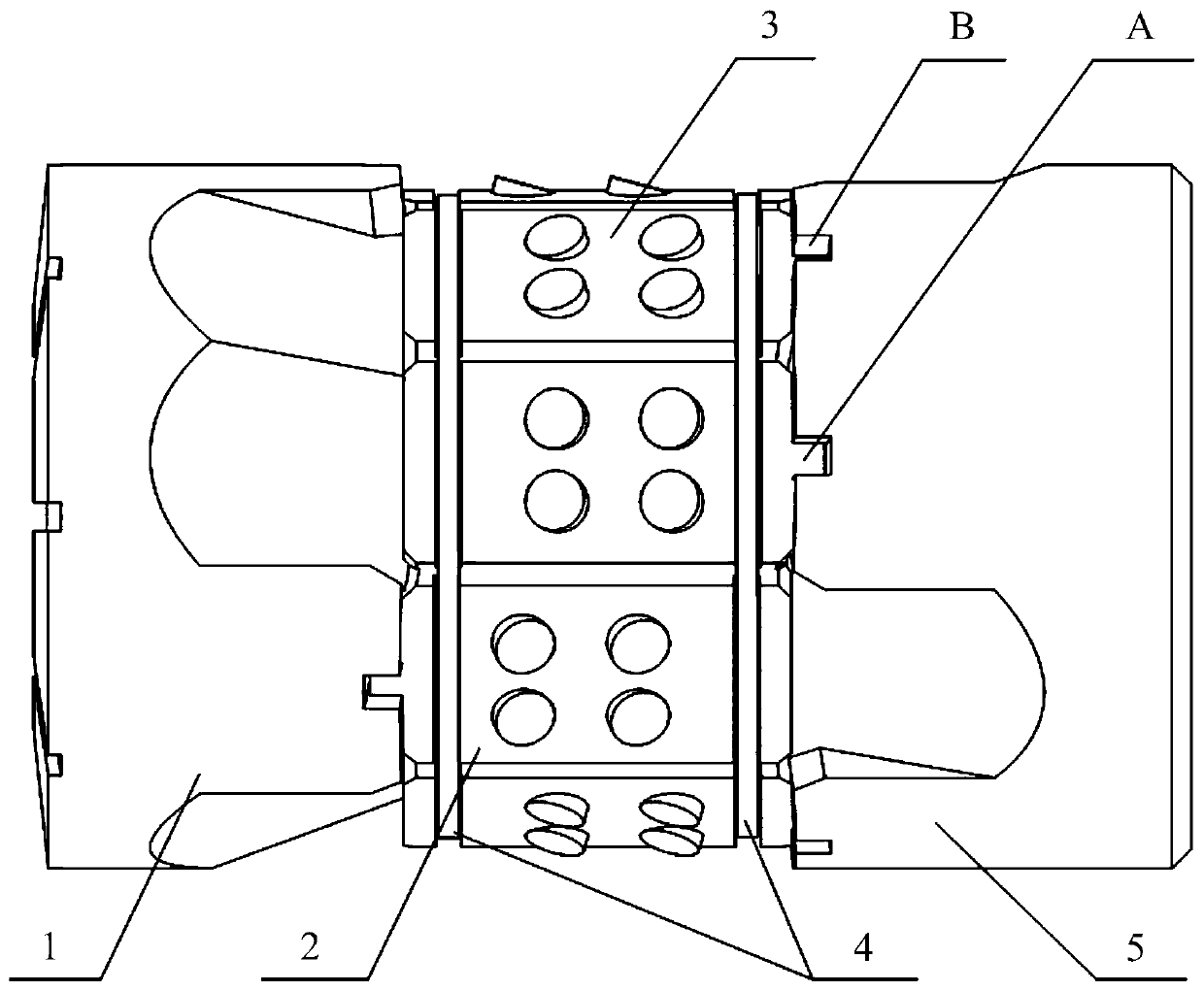

[0013] Specific embodiments: The present invention will be further described in detail below in conjunction with the accompanying drawings, which consists of an upper baffle 1, an O-ring 2, an upper joint 3, an anti-rotation pin 4, a lower baffle 5, and a lower joint 6; wherein the upper baffle 1 is threadedly connected with upper joint 3 and sealed by O-ring 2; upper joint 3 is threaded with lower joint 6 and sealed by O-ring 2; upper joint 3 and lower joint 6 are fixedly connected by anti-rotation pin 4; The baffle 5 is inserted into the lower joint 6 and sealed by the O-ring 2 .

[0014] The upper baffle plate 1 is a corrosion-resistant and easy-to-drill polymer material.

[0015] The lower baffle 5 is a magnesium-based soluble alloy material, and the lower end of the lower baffle 5 is sprayed with a corrosion-resistant polytetrafluorocoating 8 .

[0016] A hydraulic cavity 7 is opened inside the upper joint 3 .

[0017] When used on site, after the drilling is completed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com