A kind of water-soluble polyurethane rubber and its preparation method and rubber product

A technology of water-soluble polyurethane and polyurethane rubber, which is applied in the field of rubber processing and application, can solve problems such as insufficient pressure bearing capacity and poor mechanical properties, and achieve the effect of improving mechanical properties, good solubility and mechanical properties, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

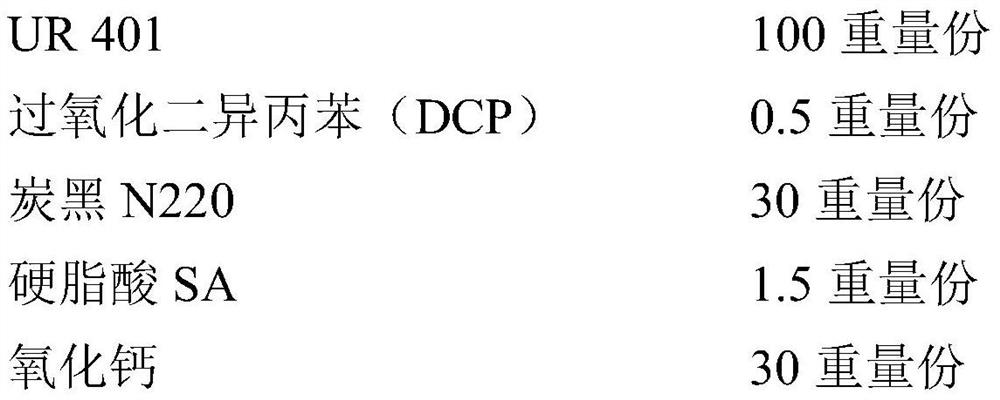

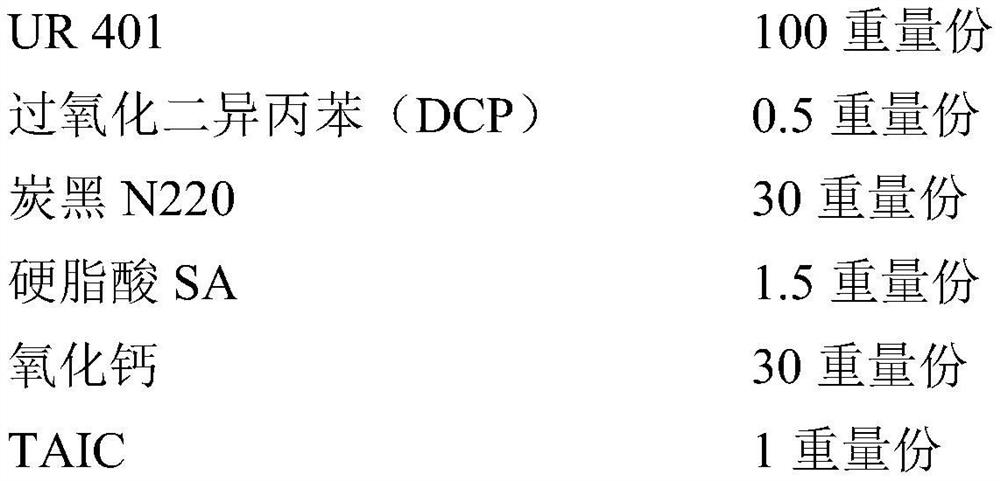

[0040]This embodiment provides a water-soluble polyurethane rubber whose formula is shown in Table 1 below.

[0041]Table 1 The formula of the water-soluble polyurethane rubber in Example 1

[0042] Component name Product model / name Parts by weight Polyurethane rubber UR 401 100 Crosslinking agent Dicumyl peroxide (DCP) 2 Reinforcing agent Carbon black N220 30 Co-crosslinking agent / 0 Processing aids Stearic acid SA 1.5 Hydrolyzing agent Calcium Oxide 30

[0043]According to the above ratio, mix all the components on an open mill (at room temperature, the temperature of the two rolls of the mill is controlled by reflux water to not exceed 35°C, thin through, and triangulate 13-17 times), park for 8 Hours later, vulcanize on a flat vulcanizing machine (170℃×t90), take out the sample and test its mechanical properties. The test results are shown in Table 2. Among them, the tensile strength and elongation at break are in accordance with the national standard GB / T 528-2009 "Determination of ...

Embodiment 2

[0058]Example 2 and Example 3 respectively provide a water-soluble polyurethane rubber. The formulations of the two are basically the same as those of Example 1. The only difference lies in the amount of hydrolyzing agent added. Specifically, based on 100 parts by weight of the polyurethane rubber UR 401, the addition amount of the hydrolyzing agent calcium oxide in Example 4 and Example 5 is 10 parts by weight and 60 parts by weight, respectively.

[0059]The mixing and vulcanization were carried out in the same process as in Example 1, and the test was performed under the same conditions as in Example 1. The mechanical properties and solubility test results of the obtained water-soluble polyurethane vulcanized rubber are shown in Table 3.

[0060]Table 3 Comparison of properties of water-soluble polyurethane rubber in Examples 1-3

[0061] Numbering Example 1 Example 2 Example 3 Calcium oxide, parts by weight 301060 Hardness, Shore A 878292 Tensile strength, MPa 24.627.412.6 Elongation...

Embodiment 4

[0066]Example 4 and Example 5 respectively provide a water-soluble polyurethane rubber. The formula of the two is basically the same as that of Example 1. The only difference lies in the type of crosslinking agent. Specifically, the choice of crosslinking agent in Example 4 Bis-(tert-butylperoxyisopropyl)benzene (BIBP), the cross-linking agent in Example 4 is 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane (bis-two Fives).

[0067]The mixing and vulcanization were carried out according to the preparation process completely consistent with Example 1, and the test was conducted under the same conditions as in Example 1. The mechanical properties and solubility test results of the obtained polyurethane vulcanized rubber are shown in Table 4.

[0068]Table 4 Comparison of properties of water-soluble polyurethane rubber in Examples 1, 4-5

[0069] Numbering Example 1 Example 4 Example 5 Type of crosslinking agent DCP BIBP Double two five Hardness, Shore A 877475 Tensile strength, MPa 24.620.122...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com