Temperature-resistant and salt-resistant fluid loss additive emulsion and preparation method thereof

A technology of fluid loss control agent and emulsion, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high polymer molecular weight, slow dissolution rate, inconvenient on-site use, etc., and achieve good fluid loss control effect , strong temperature resistance, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Dissolve 38g AM, 9g NVP, 5g DMDAAC, and 15g AMPS in 110mL water, adjust to pH=12 with NaOH, and obtain an aqueous solution;

[0027] 2) Add 110mL of white oil and 10g of sorbitan oleate into a three-necked flask, stir for 10min under nitrogen at room temperature, then add the above aqueous solution, then raise the temperature to 50°C, add 0.5g of azobisisobutyronitrile, react for 8h, and prepare Obtain temperature-resistant and salt-resistant fluid loss reducer emulsion.

Embodiment 2

[0029] 1) Dissolve 25g AM, 3g NVP, 1g DMDAAC, 6g AMPS in 115mL water, adjust to pH=9 with NaOH, and obtain an aqueous solution;

[0030] 2) Add 200 mL of white oil and 6 g of glycerol monooleate into the three-necked bottle, stir at room temperature with nitrogen for 15 minutes, and then add the above aqueous solution;

[0031] 3) Raise the temperature to 40°C, add 0.5 g of ammonium persulfate, and react for 2 hours to prepare a temperature-resistant and salt-resistant fluid loss reducer emulsion.

Embodiment 3

[0033] 1) Dissolve 30g AM, 7g NVP, 3g MDAAC, 10g AMPS in 70mL water, adjust to pH=11 with NaOH, and obtain an aqueous solution;

[0034] 2) Add 100 mL of white oil, 6 g of glycerol monostearate, and 6 g of polyoxyethylene monopalmitate into a three-necked bottle, stir at room temperature with nitrogen for 20 minutes, and then add the above aqueous solution;

[0035] 3) Raise the temperature to 45°C, add 0.5 g of dibenzoyl peroxide, and react for 4 hours to prepare a temperature-resistant and salt-resistant fluid loss reducer emulsion.

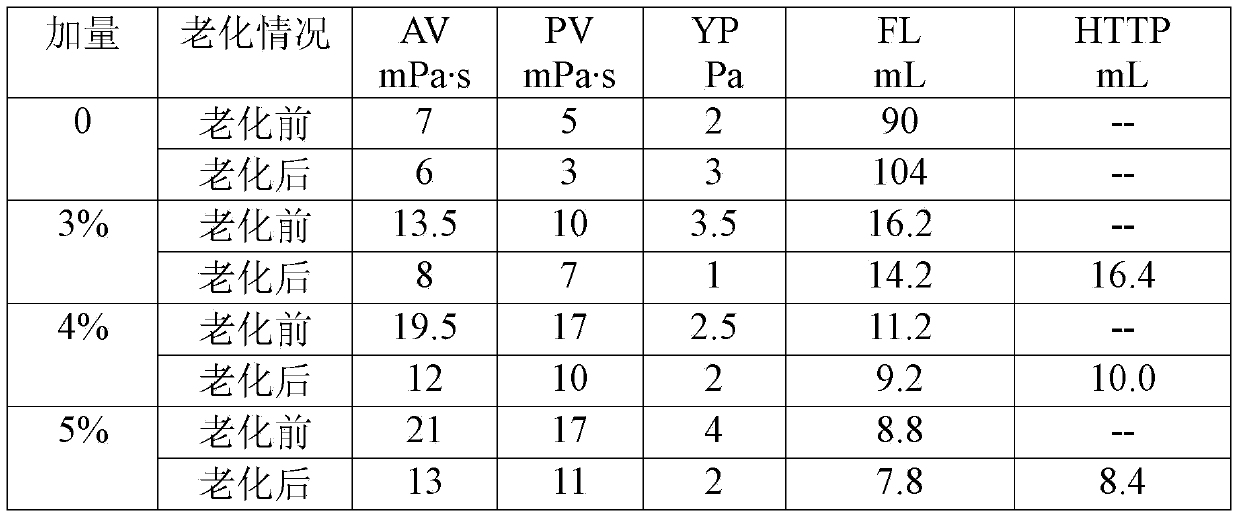

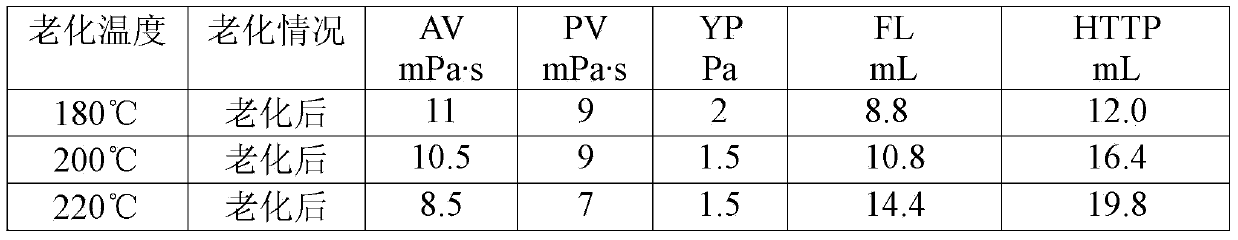

[0036] 3. Evaluation of temperature resistance and fluid loss effect of fluid loss reducer emulsion for temperature and salt resistance

[0037] Prepare saturated brine base slurry: put 350ml of saturated brine in a tall stirring cup, add 1.00g of NaHCO3 and 35.00g of evaluation soil, stir for 20min, and stop at least twice to scrape the wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com