Granular water-soluble fertilizer and preparation method thereof

A water-soluble fertilizer and granule technology, applied in nitrogen fertilizer, potash fertilizer, magnesium fertilizer, etc., can solve the problems of inconvenient transportation of liquid water-soluble fertilizer, inconvenient use of powder water-soluble fertilizer, and unacceptable user acceptance, etc. accepted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

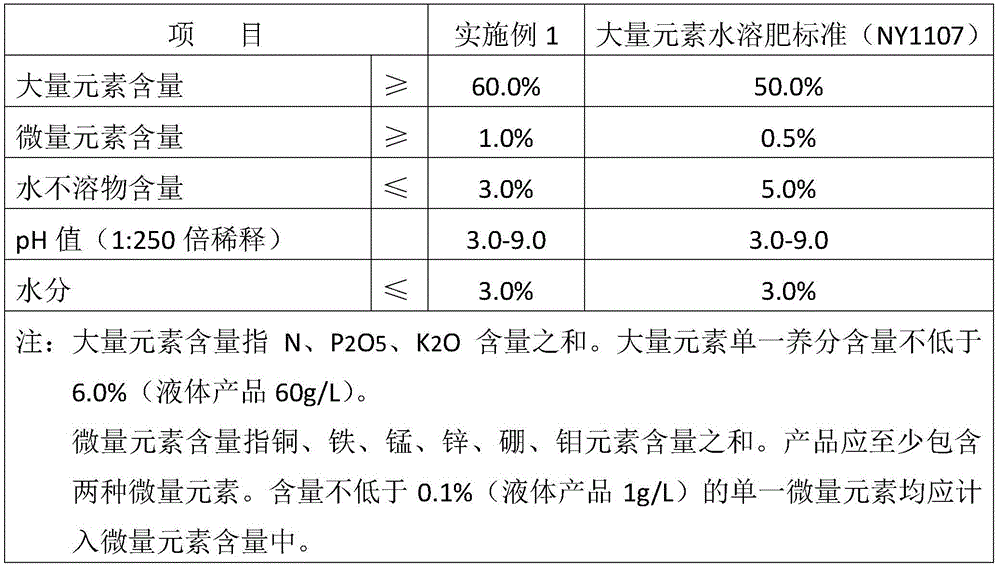

Embodiment 1

[0018] The granular water-soluble fertilizer described in this embodiment is formulated according to the following raw material formula: 83% of ammonium sulfate, 5% of potassium sulfate, 5% of magnesium sulfate, 2.5% of potassium fulvic acid, 1% of ethylenediaminetetraacetic acid, molasses fermentation broth 3.5%.

[0019] The preparation method of granular water-soluble fertilizer described in the present embodiment comprises the following steps:

[0020] 1. Weigh various raw materials according to the raw material formula for later use;

[0021] 2. Add ammonium sulfate, potassium sulfate, and magnesium sulfate to the crusher, grind and refine, and send them to No. 1 mixer through the elevator;

[0022] 3. While feeding the mixture of ammonium sulfate, potassium sulfate and magnesium sulfate into No. 1 mixer, add potassium fulvic acid, 1 / 2 amount of ethylenediaminetetraacetic acid and 2 / 5 amount of molasses fermentation broth into No. 1 blender ; In the No. 1 mixer, fully s...

Embodiment 2

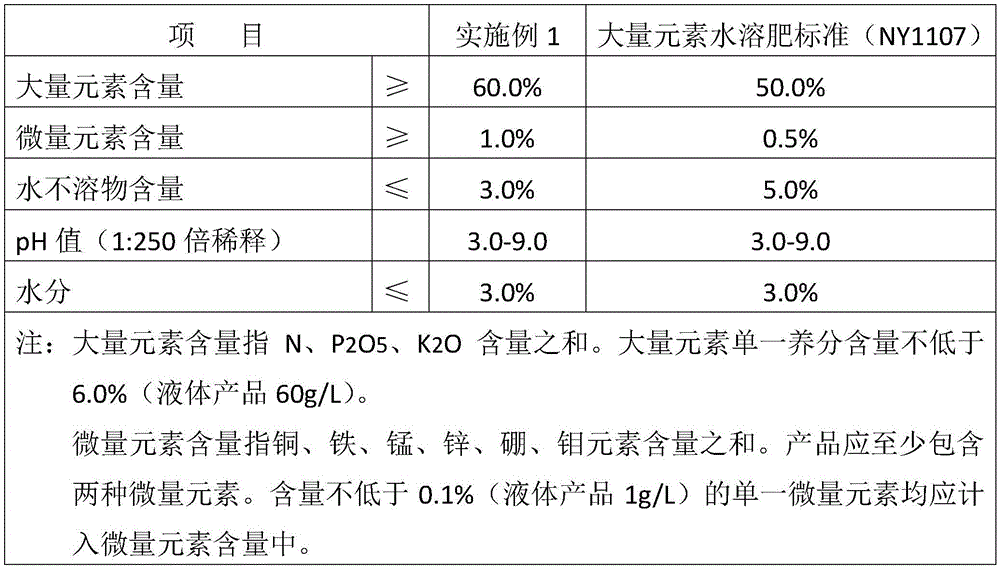

[0030] The granular water-soluble fertilizer described in this embodiment is prepared according to the following raw material formula: 86% of ammonium sulfate, 4.8% of potassium sulfate, 3% of magnesium sulfate, 3% of potassium fulvic acid, 1.2% of ethylenediaminetetraacetic acid, molasses fermentation broth 2%.

[0031] The preparation method of granular water-soluble fertilizer described in the present embodiment comprises the following steps:

[0032] 1. Weigh various raw materials according to the raw material formula for later use;

[0033] 2. Add ammonium sulfate, potassium sulfate, and magnesium sulfate to the crusher, grind and refine, and send them to No. 1 mixer through the elevator;

[0034] 3. While feeding the mixture of ammonium sulfate, potassium sulfate and magnesium sulfate into No. 1 mixer, add potassium fulvic acid, 1 / 2 amount of ethylenediaminetetraacetic acid and 2 / 5 amount of molasses fermentation broth into No. 1 blender ; In the No. 1 mixer, fully sti...

Embodiment 3

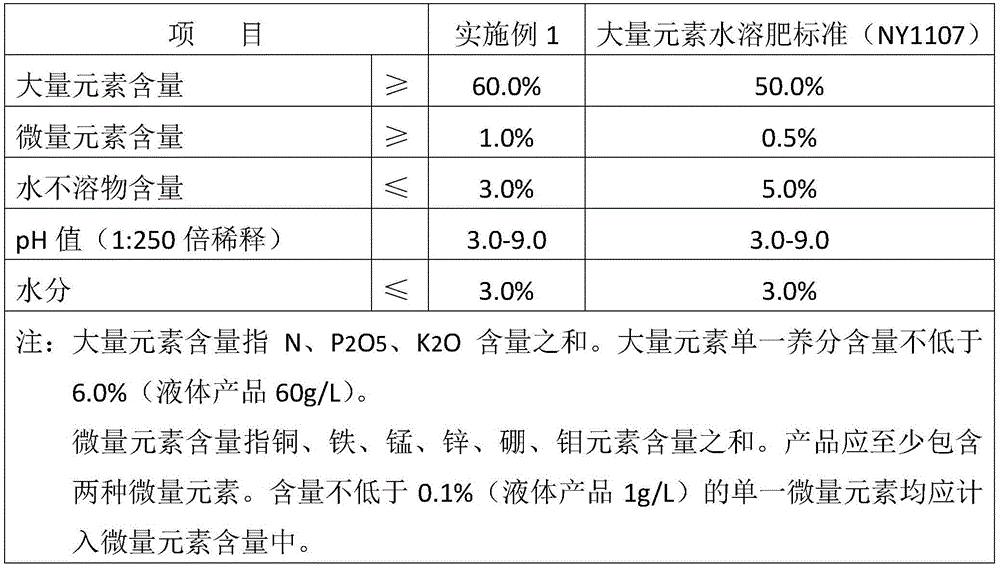

[0042] The granular water-soluble fertilizer is formulated according to the following raw material formula: 85% of ammonium sulfate, 5.2% of potassium sulfate, 3% of magnesium sulfate, 2.5% of potassium fulvic acid, 1.2% of ethylenediaminetetraacetic acid, and 3.1% of molasses fermentation liquid.

[0043] The preparation method of granular water-soluble fertilizer described in the present embodiment comprises the following steps:

[0044] 1. Weigh various raw materials according to the raw material formula for later use;

[0045] 2. Add ammonium sulfate, potassium sulfate, and magnesium sulfate to the crusher, grind and refine, and send them to No. 1 mixer through the elevator;

[0046] 3. While feeding the mixture of ammonium sulfate, potassium sulfate and magnesium sulfate into No. 1 mixer, add potassium fulvic acid, 1 / 2 amount of ethylenediaminetetraacetic acid and 2 / 5 amount of molasses fermentation broth into No. 1 blender ; In the No. 1 mixer, fully stir and mix variou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com