Dispersion polymeric acrylamide emulsion and its application in oil field produced liquid treatment

A polyacrylamide and production fluid technology, applied in the direction of washing/replacing pulp treatment fluid, flocculation/sedimentation water/sewage treatment, reinforcement addition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

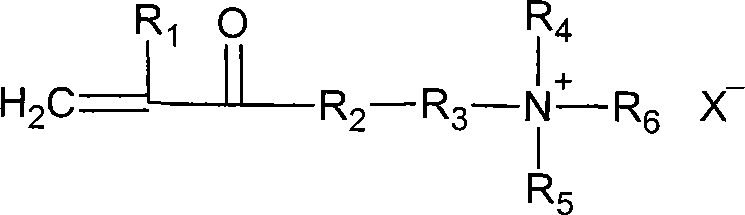

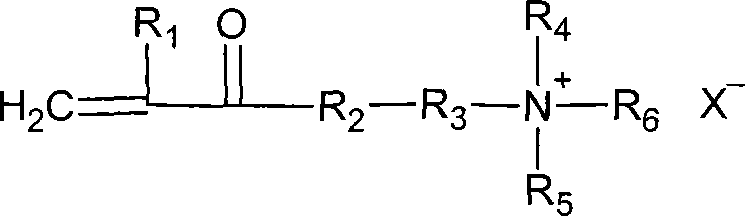

Method used

Image

Examples

Embodiment 1

[0060] In a 100L reactor with a stirrer, a temperature controller and a water-cooled condenser, add:

[0061] Acrylamide 5.0kg

[0062] Polymethacryloxyethyl dimethylbenzyl ammonium chloride (IV=300ml / g) 5.0kg

[0063] Hyperbranched polyester with hydroxyl terminal 0.02kg

[0064] Polyethylene glycol 600 10.0kg

[0066] Ammonium phosphate 27.0kg

[0067] Ammonium persulfate 0.006kg

[0068] Sodium bisulfite 0.006kg

[0069] Chelating agent disodium ethylenediaminetetraacetic acid (EDTA) 0.04kg

[0070] Deionized water balance

[0071] The above materials total 100kg,

[0072] In addition to the initiator, the reactor containing the above-mentioned other materials is kept at a constant temperature of 15°C, stirred at 500 rpm, and then the solution is bubbled with 1000 ml / min of nitrogen to remove oxygen in the system. After nitrogen is blown for about 15 minutes, 0.006kg of ammonium persulfate and 0.006kg of sodium bisulfite are added. The polymerizat...

Embodiment 2

[0073] Example 2 (comparative example, no hyperbranched polymer AB is added to the system 2 )

[0074] In a 100L reactor with a stirrer, a temperature controller and a water-cooled condenser, add:

[0075] Acrylamide 5.0kg

[0076] Polymethacryloxyethyl dimethylbenzyl ammonium chloride (IV=300ml / g) 5.0kg

[0077] Polyethylene glycol 600 0.2kg

[0078] Sodium chloride 5.0kg

[0079] Ammonium phosphate 27.0kg

[0080] Ammonium persulfate 0.006kg

[0081] Sodium bisulfite 0.006kg

[0082] Chelating agent disodium ethylenediaminetetraacetic acid (EDTA) 0.04kg

[0083] Chain transfer agent sodium formate 0.04kg

[0084] Deionized water balance

[0085] The above materials total 100kg,

[0086] In addition to the initiator, the reactor containing the above-mentioned other materials is kept at a constant temperature of 15°C, stirred at 500 rpm, and then the solution is bubbled with 1000 ml / min of nitrogen to remove oxygen in the system. After blowing nitrogen for about 15 minutes, add 0.00...

Embodiment 3

[0088] In a 100L reactor with a stirrer, a temperature controller and a water-cooled condenser, add:

[0089] Acrylamide 6.8kg

[0090] Methacryloxyethyl dimethylbenzyl ammonium chloride (80% aqueous solution) 4.0kg

[0091] Polymethacryloxyethyl trimethylammonium chloride (IV=120ml / g) 10.0kg

[0092] Hyperbranched polyester with hydroxyl terminal 0.1kg

[0093] Polyethylene glycol 200 0.8kg

[0094] Sodium chloride 2.0kg

[0095] Sodium sulfate 10.0kg

[0096] Ammonium hydrogen phosphate 28.0kg

[0097] 2,2'-Azobis(2-amidinopropane) dihydrochloride 0.02kg

[0098] Chelating agent disodium ethylenediaminetetraacetic acid (EDTA) 0.04kg

[0099] Chain transfer agent sodium formate 0.04kg

[0100] Deionized water balance

[0101] The above materials total 100kg,

[0102] In addition to the initiator, the reactor containing the above-mentioned other materials is kept at a constant temperature of 45° C., stirred at 400 rpm, and then the solution is bubbled with 1000 ml / min of nitrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com