Method for preparing cement clinker by utilizing sludge

A technology for cement clinker and sludge, which is applied in the field of cement clinker, can solve the problem of high water demand of standard consistency, and achieve the effects of low hydration heat, reduced discharge and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

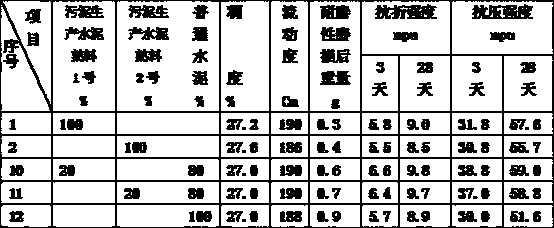

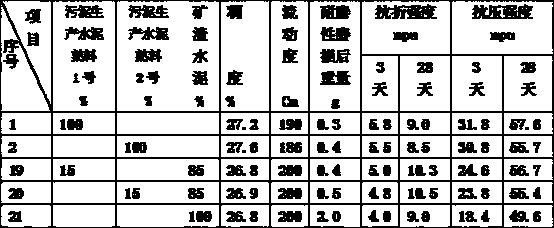

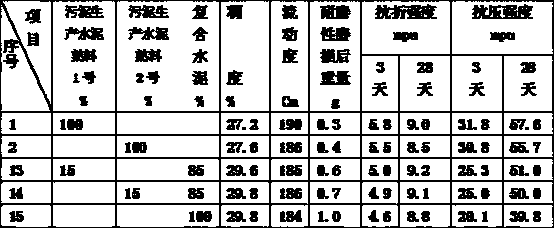

Examples

example 2

[0016] Example 2: Take sludge as 80% by weight percentage, silica fume slag as 15% by weight percentage, and zeolite as 5% by weight percentage;

example 3

[0017] Example 3: Take sludge as 75% by weight percentage, silica fume slag as 15% by weight percentage, and zeolite plaster as 10% by weight percentage:

example 4

[0018] Example 4: Take sludge as 75% by weight percentage, silica fume slag as 20% by weight percentage, and zeolite as 5% by weight percentage:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com