Process for modifying reaction at surface of separating film of polymer

A grafting reaction and separation membrane technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve problems such as large application limitations, limited depth and degree of grafting, and limited separation membranes. Clean processing, easy control of grafting degree, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

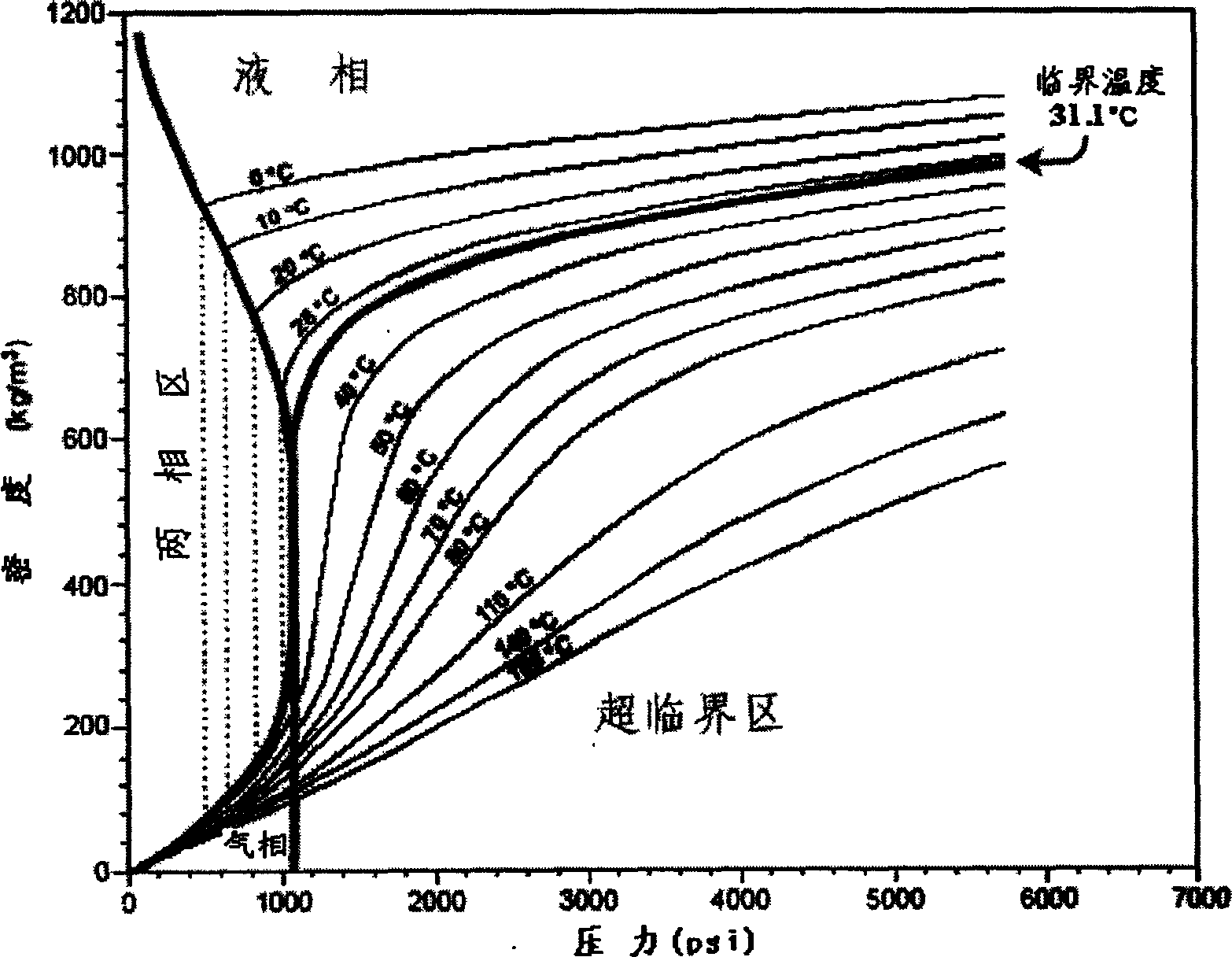

Embodiment 1

[0026] Fix the PVDF microporous membrane (flat membrane, 10 cm × 20 cm) on a support with a certain shape, and place it in 1000ml cylindrical supercritical CO 2 The reactor (φ68mm / 400mm) is airtight, and then the temperature is raised to 35°C, pressurized to 9MPa, pre-soaked for 0.5 hours, open the pressure reducing valve to slowly drain the CO 2 , For the next step of grafting reaction. Then in CO 2 Under the atmosphere, 50 g of a mixed monomer of styrene (St) and maleic anhydride (MAH) (molar ratio 1:1) and 0.28 g of azoisobutyronitrile (AIBN) were sequentially added to the reactor, and the reactor was sealed. Open CO 2 The intake valve is pressurized, and at the same time the temperature is raised to a supercritical state (temperature 60°C, pressure 7.38MPa), constant temperature and constant pressure reaction for 1 hour. Open the pressure reducing valve and slowly vent until the pressure in the reactor is zero. Take out the grafted modified membrane and soak it in acetone for ...

Embodiment 2

[0028] The operation is the same as in Example 1. The modified base film is changed to PAN microporous film, the graft comonomer is changed to 1.6g itaconic anhydride (ITA), the initiator is changed to 0.03g benzoyl peroxide (BPO), and the reaction is closed. kettle. Open CO 2 The intake valve is pressurized, and the temperature is raised to a supercritical state (temperature 80°C, pressure 20MPa), and reacts at constant temperature and pressure for 10 hours. The grafted modified membrane was characterized by ATR-IR, XPS, elemental analysis and scanning electron microscopy, and the grafting rate was 6.8%.

Embodiment 3

[0030] Fix the PP dense non-porous membrane (flat membrane, 10 cm × 20 cm) on a support with a certain shape, and place it in supercritical CO 2Pre-soak in the reactor for 1 hour, and the operation is the same as in Example 1. Take out the PP microporous film, quickly put it into the plasma generator, adjust the vacuum to 20Pa under argon atmosphere, and irradiate 100W plasma for 10-20 minutes. After plasma irradiation The membrane is exposed to the air for 15 minutes, and then quickly moved into the supercritical CO 2 In the reactor; in CO 2 Under the atmosphere, 3.4 g of hydroxyethyl methacrylate monomer (HEMA) was sequentially added to the reaction kettle, and the reaction kettle was sealed. Open CO 2 The intake valve is pressurized, and the temperature is raised to a supercritical state (temperature 60°C, pressure 30MPa), and reacts at constant temperature and pressure for 4 hours. Open the pressure reducing valve and slowly exhaust until the pressure of the reactor is zero, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com