Preparation method of polylactic acid functionalized graphene

A technology of polylactic acid and fossils, which is applied in the field of preparing polylactic acid functionalized graphene, can solve the problems of difficult interface bonding and low chemical activity, and achieve the effect of rich oxygen-containing functional groups, high grafting rate, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Firstly, graphite was prepared into graphite oxide according to the improved Hummers method. The specific method was to slowly add 21 g of flake graphite / potassium permanganate mixed solid with a mass ratio of 1:6 to 400 mL of H2O with a volume ratio of 9:1. 2 SO 4 / H 3 PO 4 In the mixed solution, after mixing evenly, place it in a constant temperature water bath at 50°C and continue to stir for 12 hours, then pour in H 2 o 2 Stand still in an ice bath for 24 hours, then repeatedly centrifuge and wash with deionized water until neutral, and then vacuum-dry at a temperature of 45° C. to obtain graphite oxide. The above-mentioned graphite oxide was prepared into a 1 mg / ml graphite oxide aqueous solution, then ultrasonically oscillated at room temperature for 2.5 hours to peel off the graphite oxide, and finally freeze-dried at a temperature of -50° C. to obtain powdered graphene oxide.

[0017] Then add 120ml of lactic acid into a 250ml reaction bottle, then place it ...

Embodiment 2

[0020] Graphene oxide was prepared by the method of Example 1.

[0021] Then add 120ml of lactic acid into a 250ml reaction bottle, then place it in an oil bath at 100°C, and conduct vacuum distillation and dehydration under a vacuum of 300Pa for 4 hours to obtain anhydrous lactic acid.

[0022] Then, 0.5 g of powdered graphene oxide and 0.3 g of stannous chloride as a catalyst were added to the above reaction flask, ultrasonically treated for 5 min, and then melted and polycondensed at a temperature of 170° C. and a vacuum of 70 Pa for 8 h. The reaction liquid was cooled, and then repeatedly dissolved with chloroform to wash away the polylactic acid not covalently bonded to graphene, and finally vacuum-dried at 50 °C for 24 h to obtain GO-g-PLA.

Embodiment 3

[0024] Graphene oxide was prepared by the method of Example 1.

[0025] Then add 120ml of lactic acid into a 250ml reaction bottle, then place it in an oil bath at 100°C, and conduct vacuum distillation and dehydration under a vacuum of 300Pa for 4 hours to obtain anhydrous lactic acid.

[0026] Then, 0.8 g of powdered graphene oxide and 0.3 g of stannous octoate as a catalyst were added to the above reaction flask, ultrasonically treated for 5 min, and then melted and polycondensed at a temperature of 170° C. and a vacuum of 70 Pa for 12 h. The reaction solution was cooled and dissolved repeatedly with chloroform to wash away polylactic acid not covalently bonded to graphene, and finally dried in vacuum at 50°C for 24 hours to obtain GO-g-PLA.

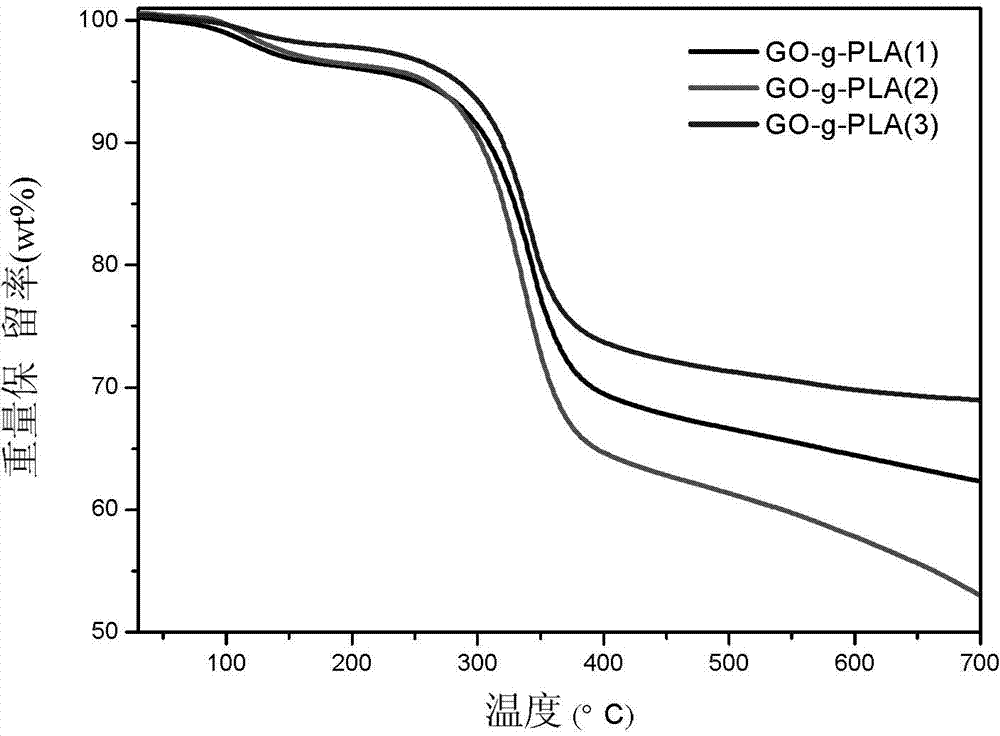

[0027] The present inventor has carried out the thermogravimetric analysis experiment to the GO-g-PLA that is prepared by the above-mentioned embodiment at the temperature of 30 ℃~700 ℃, under the protection of nitrogen, the thermogra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com