Low temperature impact resistant nylon flexibilizer and preparation method of low temperature impact resistant nylon flexibilizer

A technology of toughening agent and low temperature resistance, which is applied in the field of nylon toughening agent and its preparation, which can solve the problems of product yellowing, mechanical property decline, difficulty in pulling strands, pelletizing, etc., and achieve high grafting rate and accurate feeding , The effect of reducing the amount of gel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

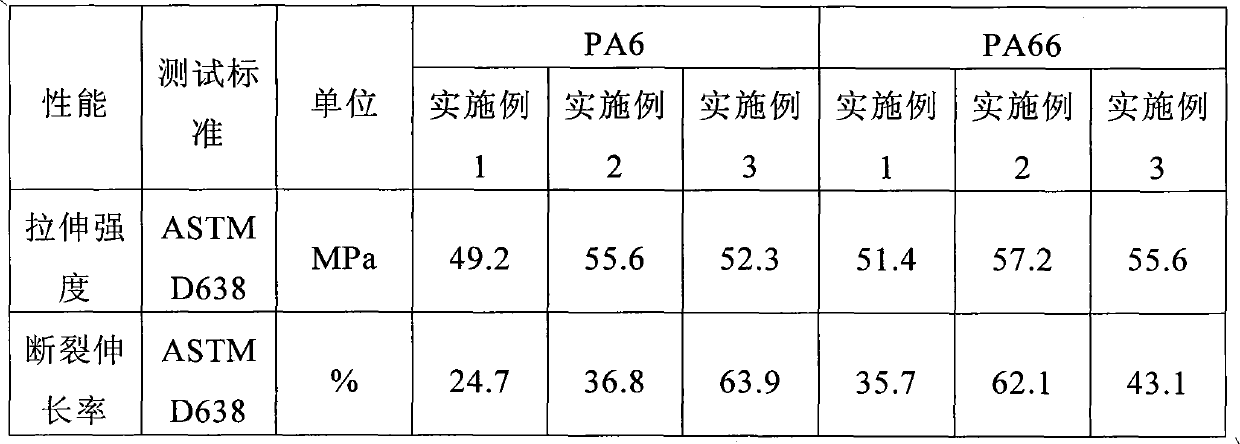

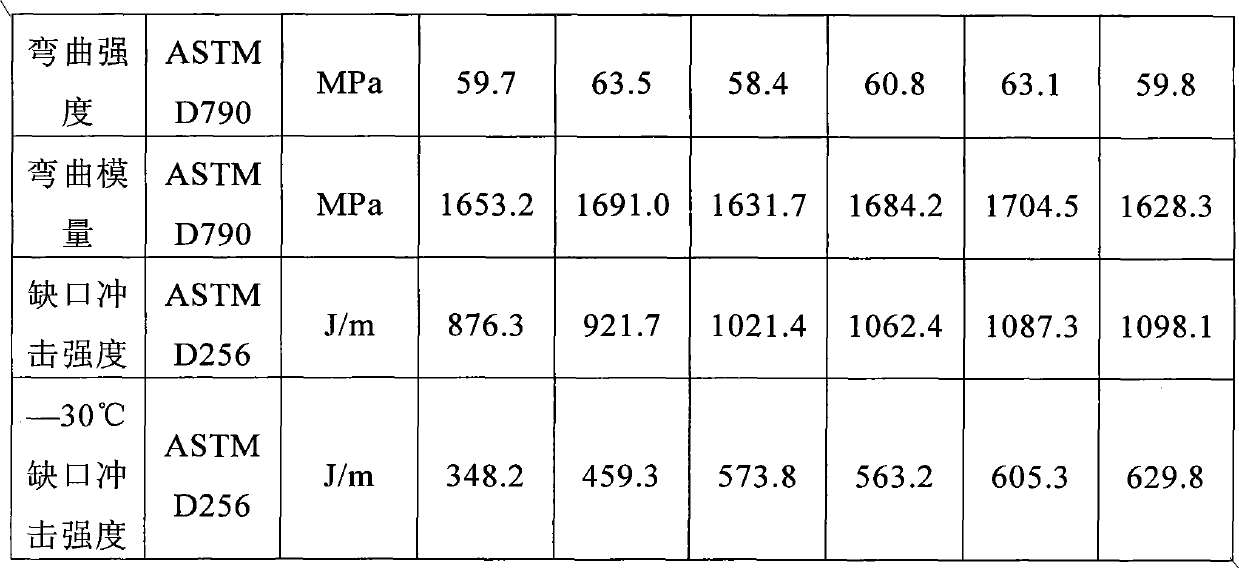

Embodiment 1

[0039] Weigh the following components in parts by weight: 70 parts of POE resin (DOW, ENGAGE 8180), 20 parts of CPP (Shanghai Secco, S2040), 10 parts of LLDPE (Korea SK, JL210), and the graft monomer is maleic anhydride 2 The initiator is 0.1 part of bis(tert-butylperoxyisopropyl)benzene, 0.3 part of PE wax, 0.3 part of 1010 antioxidant, and 0.2 part of wax oil.

[0040] Put the other components except the initiator into the high-speed mixer according to the proportion and mix them for 8 minutes, then add them into the twin-screw extruder after metering through the main feeder, and add the initiator into the extruder after metering through the side feeder , the screw temperature of each section of the extruder from the feed port to the head is set between 100°C and 200°C, and the mixed material is melted and plasticized, kneaded and mixed, extruded from the head, drawn, cooled, pelletized, Dry to obtain the product.

Embodiment 2

[0042] Weigh the following components in parts by weight: 80 parts of POE resin (DOW, ENGAGE 8150), 15 parts of CPP (Shanghai Secco, S2040), 5 parts of LLDPE (Korea SK, JL210), and the graft monomer is methacrylic acid shrink 3 parts of glycerides, 0.15 parts of initiator consisting of 2,5-dimethyl-2,5-di-tert-butylperoxyhexane and dicumyl peroxide, 0.4 parts of sodium stearate, 1010 and 168 for 0.4 part of antioxidant, 0.1 part of white oil.

[0043] Put the other components except the initiator into the high-speed mixer according to the proportion and mix them for 10 minutes, then add them into the twin-screw extruder after metering through the main feeder, and add the initiator into the extruder after metering through the side feeder , the screw temperature of each section of the extruder from the feeding port to the machine head is set between 80°C and 180°C, and the mixed material is melted and plasticized, kneaded and mixed, extruded from the machine head, drawn, cooled,...

Embodiment 3

[0045] Weigh the following components by weight: 60 parts of POE resin (DOW, ENGAGE 8150), 25 parts of CPP (Shanghai Secco, S2040), 15 parts of LLDPE (Korea SK, JL210), and the grafting monomers are maleic anhydride and 3 parts of glycidyl methacrylate (1:2), the initiator consists of 0.2 parts of 2,5-dimethyl-2,5-di-tert-butylperoxyhexane, 0.4 parts of sodium stearate, 1010 and 168 It is 0.4 parts of antioxidant and 0.2 parts of white oil.

[0046] Put the other components except the initiator into the high-speed mixer according to the proportion and mix them for 5 minutes, then add them into the twin-screw extruder after metering through the main feeder, and add the initiator into the extruder after metering through the side feeder , the screw temperature of each section of the extruder from the feed port to the head is set between 110°C and 220°C, and the mixed material is melted and plasticized, kneaded and mixed, extruded from the head, drawn, cooled, pelletized, Dry to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com