Automatic feeding device and crab breeding device

An automatic feeding device, feeding device technology, applied in fish farming, application, climate change adaptation, etc., can solve the problems of laborious manual feeding, unsustainable work, unsuitable for batch farming, etc., to achieve the liberation of manpower and accurate feeding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

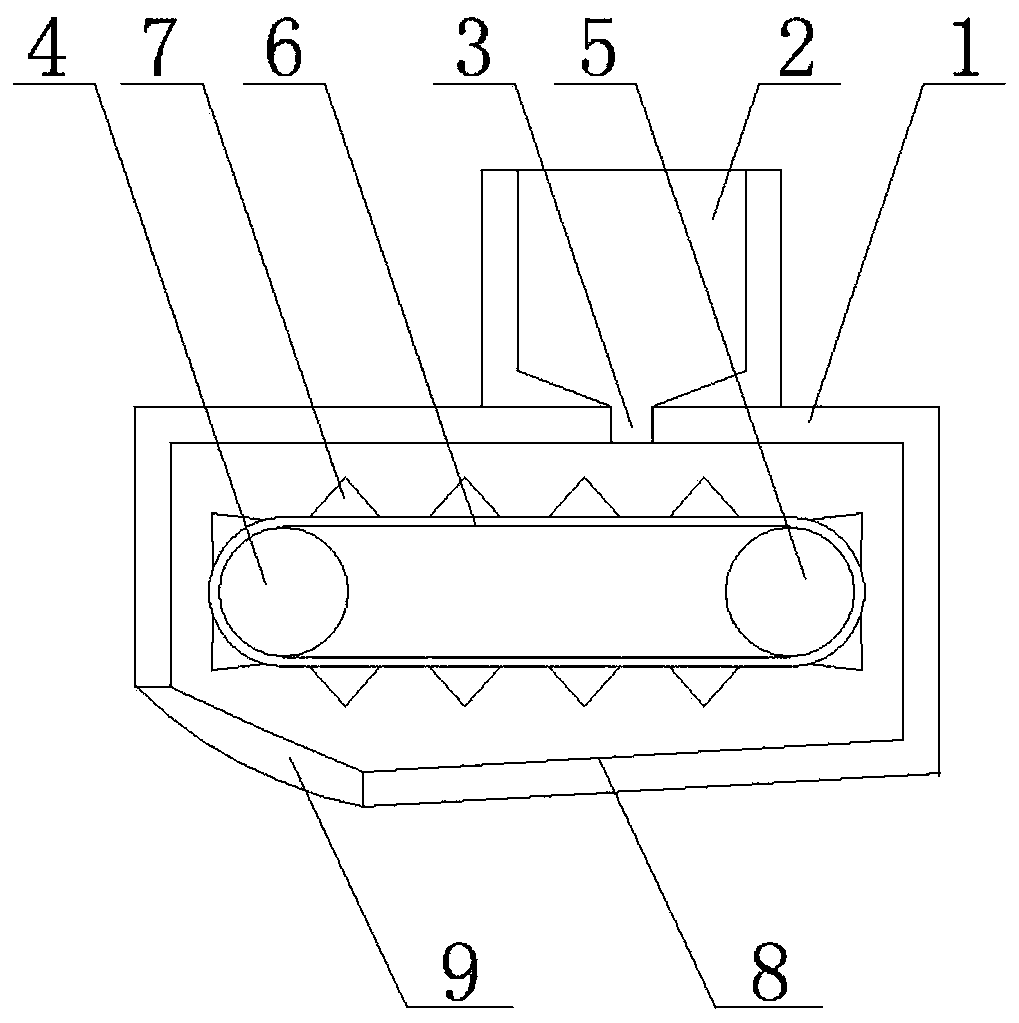

[0025] Such as figure 1 As shown, an automatic feeding device includes a feeding device main body 1, a storage bin 2, a feeding structure and a first servo motor, the feeding device main body 1 is a cuboid shell, the storage bin 2 is open at the top, and the storage bin 2 is fixed It is connected to the main body 1 of the feeding device. In this embodiment, the two are integrally formed, and a first outlet 3 passing through the storage bin 2 and the main body 1 of the feeding device is provided. The first outlet 3 includes two opening and closing ports. In the first state, the material distribution structure is arranged inside the main body 1 of the feeding device. The material distribution structure includes the first driving shaft 4, the first driven shaft 5 and the first synchronous belt 6, the first driving shaft 4 and the first driven shaft 5 The rotatable fixed connection is inside the side wall of the feeding device main body 1 (the rotatable fixed connection means that...

Embodiment 2

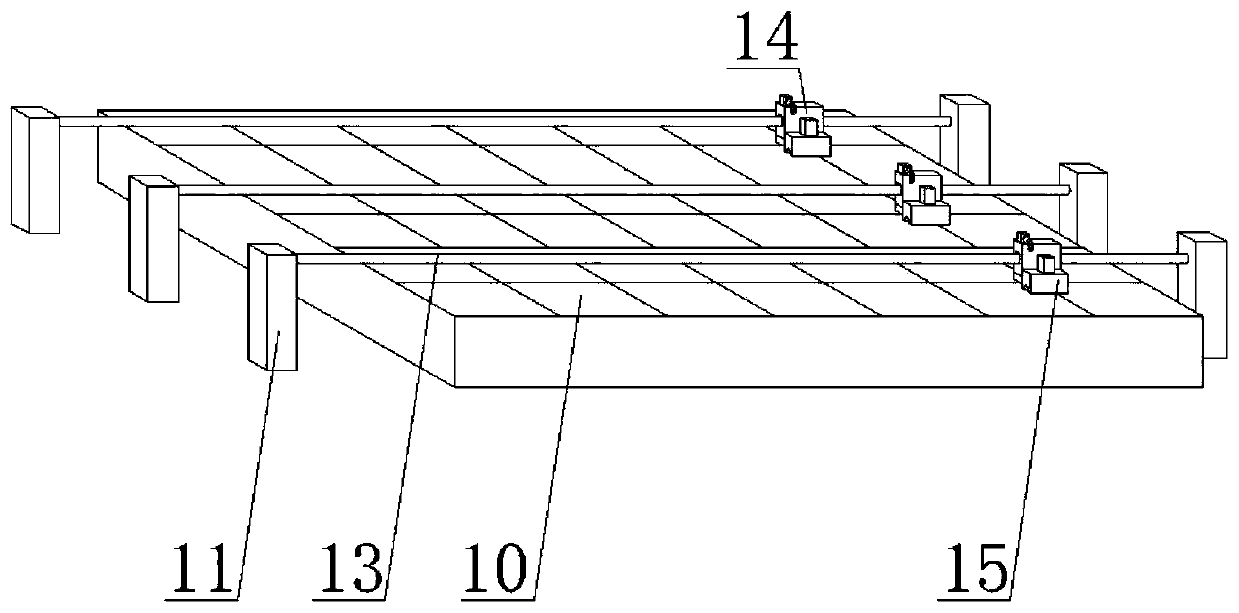

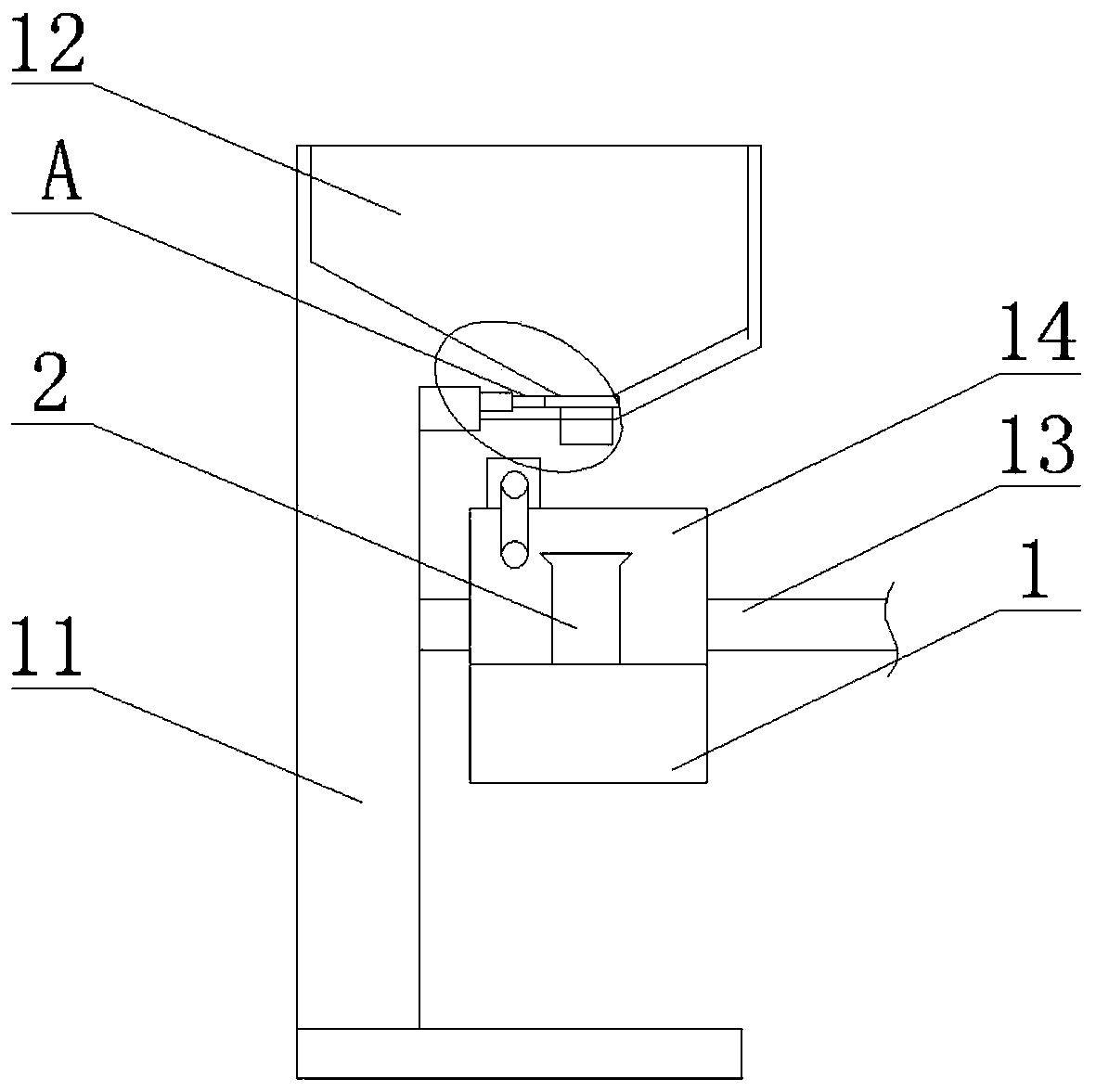

[0028] Such as Figure 2~3 As shown, a kind of crab breeding equipment includes a breeding box 10, a fixed frame 11, a feeding bin 12, a walking rod 13, a walking device 14 and an automatic feeding device 15. There are several breeding boxes 10, and several breeding boxes 10 are arranged according to the matrix Arranged in the form of a number of mutual culture boxes 10 rows, each culture box 10 columns include a number of culture boxes 10, the fixed frame 11 is at least one group, each group includes two fixed frames 11, and the two fixed frames 11 are located at At both ends of the breeding box 10 columns, the feeding bin 12 is fixedly connected to the top of any one of the two fixed frames 11 in each group, and the bottom of the feeding bin 12 is a third outlet 16 including two states of opening and closing, and the walking rod 13 is fixed. Connected between each group of two fixed frames 11, the height and position of each group of two fixed rods make the walking rod 13 ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com