Lifting appliance and method for mounting furnace rollers of annealing furnaces

A technology for annealing furnaces and furnace rolls, which is applied in the field of metal heat treatment equipment, can solve the problems of difficult loading and unloading of furnace rolls, easy equipment injury, and time-consuming problems, and achieves benefits in installation efficiency, adjustment of the axis position of furnace rolls, and safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

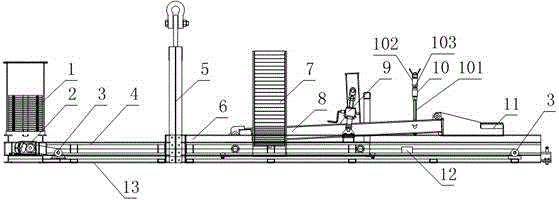

[0032] like figure 1 and figure 2 , a hanger for the installation of annealing furnace rollers, including a strip rail 13 and a moving trolley 6, the moving trolley 6 is arranged on the strip rail 13 and the moving trolley 6 can move along the length direction of the strip rail 13 movement, the moving trolley 6 is also provided with a furnace roller fixing part, and also includes a trolley braking device fixed on the strip rail 13, the trolley braking device is connected with the mobile trolley 6, and the strip rail 13 is also provided with There are counterweights;

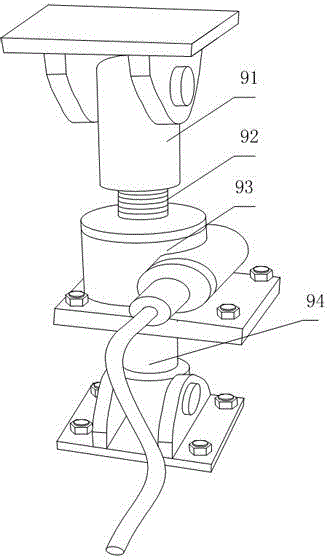

[0033] The furnace roll fixing part includes a lifting platform 8, one end of the lifting platform 8 is hingedly connected with the mobile trolley 6, the other end of the lifting platform 8 is provided with a furnace roller bracket 11, and the lifting platform 8 is also provided with a useful The lifting device 9 that brakes the lifting platform 8 to rotate around the hinge point between itself and the mobile ...

Embodiment 2

[0036] like figure 1 and figure 2 , this embodiment is further defined on the basis of Embodiment 1: as a structural form for adjusting the balance state of the strip rail 13, the counterweight includes a The fixed counterweight 1 and the movable counterweight 7 arranged between the two ends of the strip rail 13. In the above structure, the fixed counterweight 1 and the furnace roller bracket 11 can be respectively arranged at different ends of the strip rail 13, and the movable counterweight 7 is located between the two ends of the strip rail 13. Compared with using a single counterweight Block, the two counterweights can be set lighter respectively, which is convenient for the adjustment of the counterweight in the application process of the present invention.

[0037] As a way to facilitate the adjustment of the respective weights of the fixed counterweight 1 and the movable counterweight 7, the fixed counterweight 1 and the movable counterweight 7 both include a counter...

Embodiment 3

[0039] like figure 1 and figure 2 , this embodiment is further limited on the basis of Embodiment 1: as a structural form with strong movement and driving ability of the braking mobile trolley 6 and high precision of displacement adjustment of the braking mobile trolley 6, the trolley braking device includes an active The sprocket 2 , the driven sprocket 3 and the transmission chain 4 wound on the driving sprocket 2 and the driven sprocket 3 , and the moving trolley 6 is fixed on the transmission chain 4 .

[0040] In order to ensure the stability of the position of the traction force on the transmission chain 4 during the braking process of the trolley braking device as much as possible, and to facilitate the displacement adjustment accuracy of the structure and the compactness of the structure, there are more than one driven sprocket 3, and The driven sprocket 3 is arranged in a row on the bar rail 13 at the same height. Further, after the moving trolley 6 arrives at the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com