Manipulator vacuum drug absorption plate connecting and discharging mechanism

A manipulator and vacuum suction technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of slow line speed of sub-plate conveyor belt, inconvenient operation of workers, affecting production efficiency, etc., to achieve convenient production efficiency and promote fast production. Development, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with specific embodiment, further illustrate the present invention.

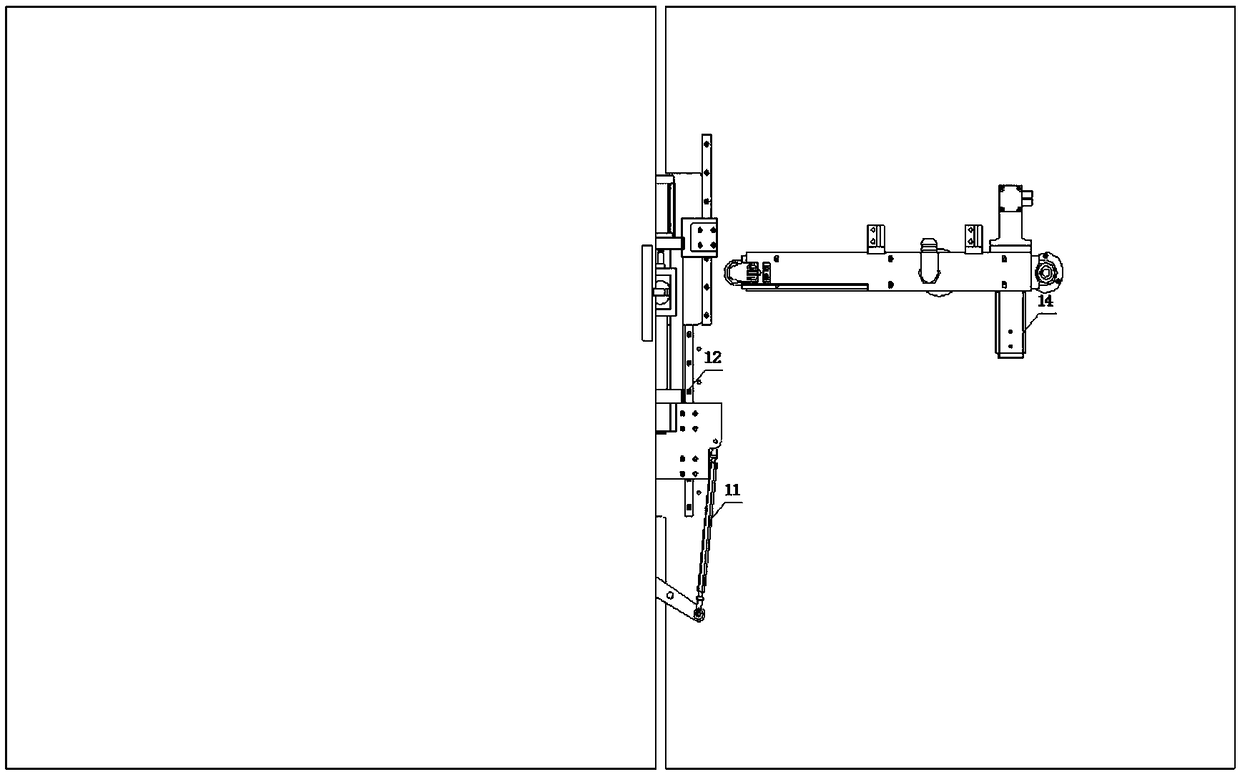

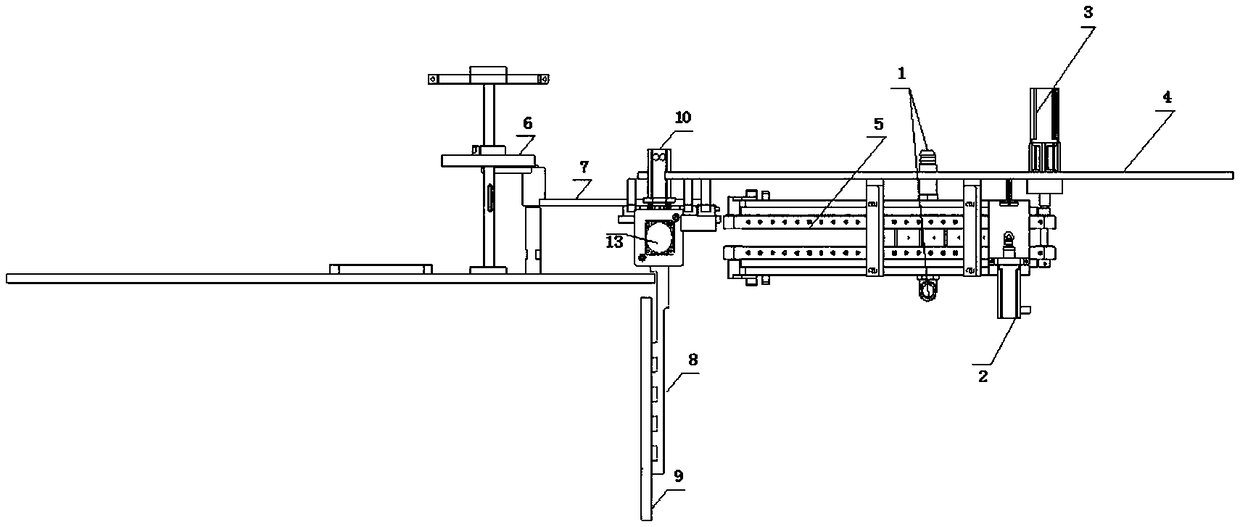

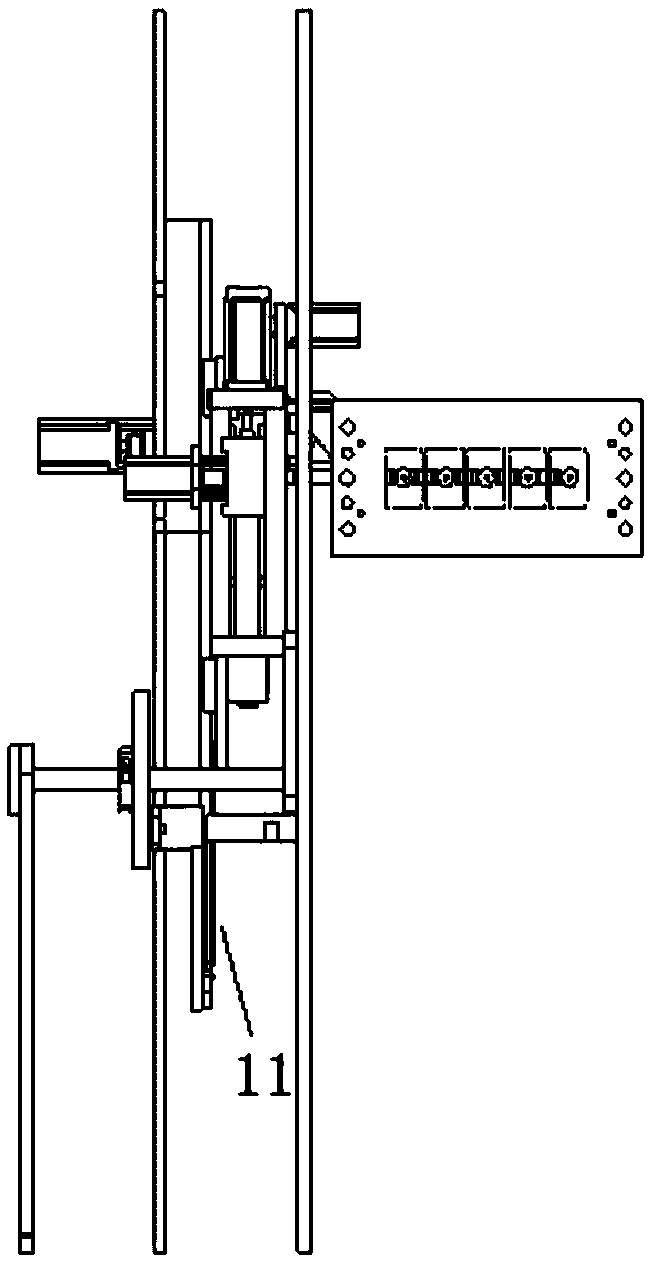

[0023] Figure 1 ~ Figure 3 The three views of the online feeding mechanism of the vacuum drug absorption plate of the manipulator provided for this embodiment, the described mechanism of the online feeding of the vacuum drug absorption plate of the manipulator includes:

[0024] The manipulator suction cup holder 8 for absorbing the punched medicine plate in the punching mechanism 9 of the aluminum-plastic machine;

[0025] The manipulator horizontal angle servo motor 13 and the manipulator vertical angle servo motor 10 for driving the manipulator suction cup frame 8 to rotate;

[0026] Vacuum timing belt 5 for conveying die-cut medicine sheets;

[0027] A vacuum synchronous belt feeding servo motor 3 for driving the vacuum synchronous belt 5;

[0028] The forced unloading servo motor 2 used to transport the medicine plate conveyed by the vacuum synchronous belt 5 to the carto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com