Application and usage of vanadium series catalyst of one-class bidentate N, O coordination

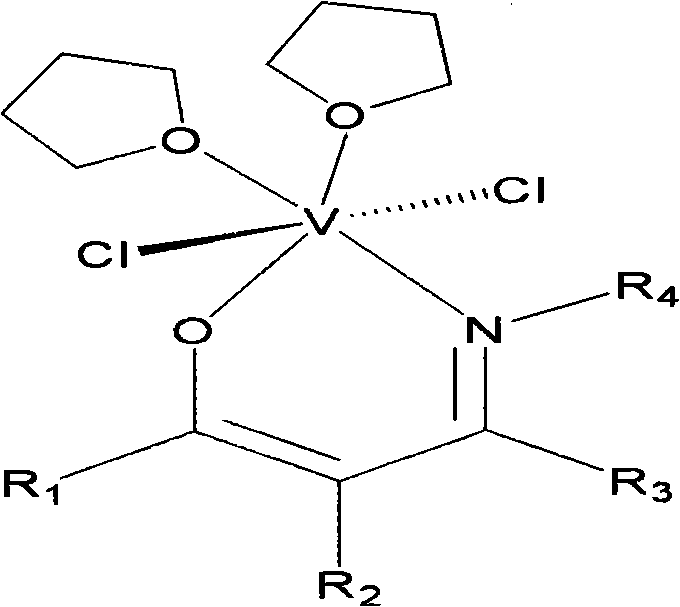

A catalyst and coordination technology, which is applied in the field of copolymerization of ethylene and polar monomers with vanadium-based catalysts, can solve problems that have not been reported in the application, and achieve the effect of avoiding poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

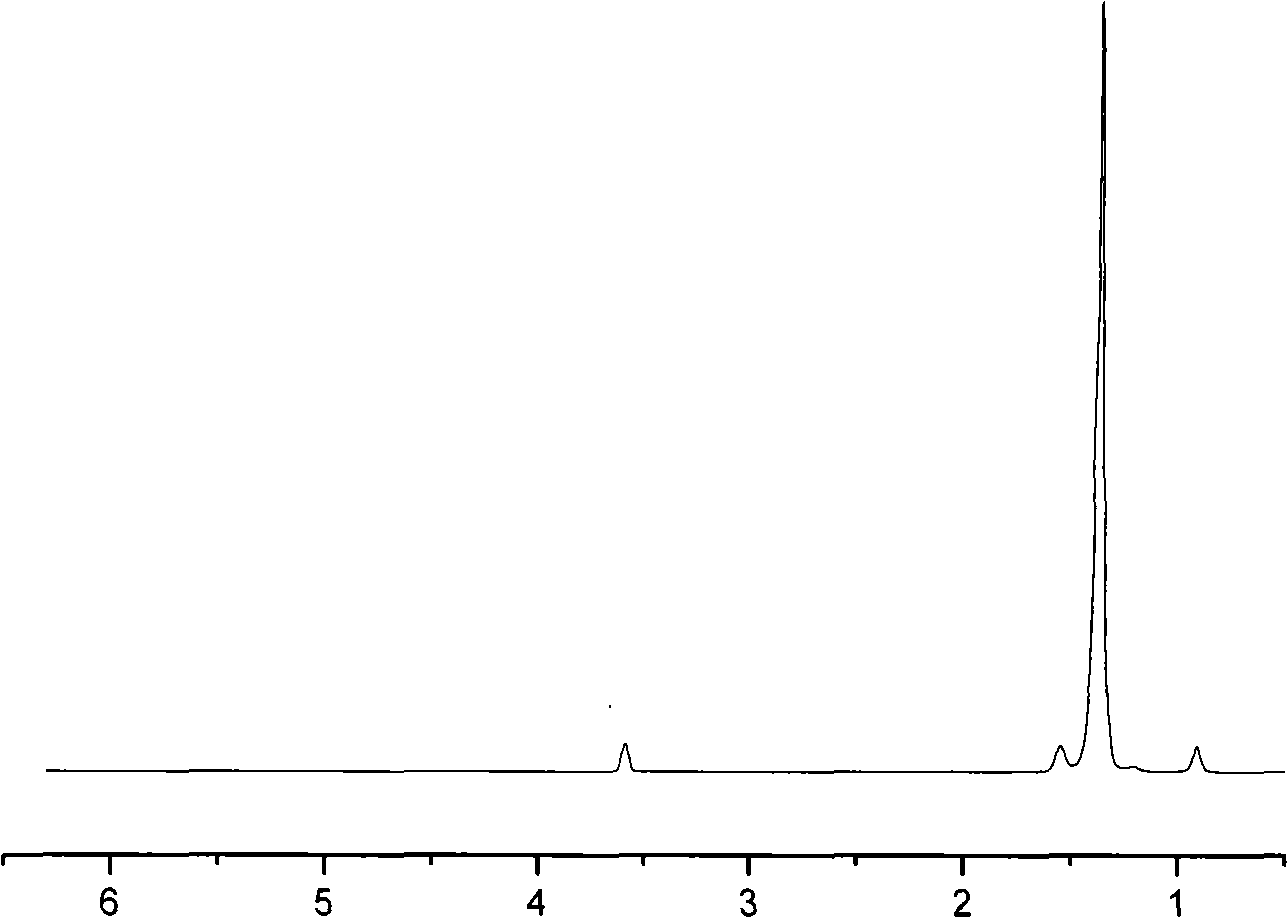

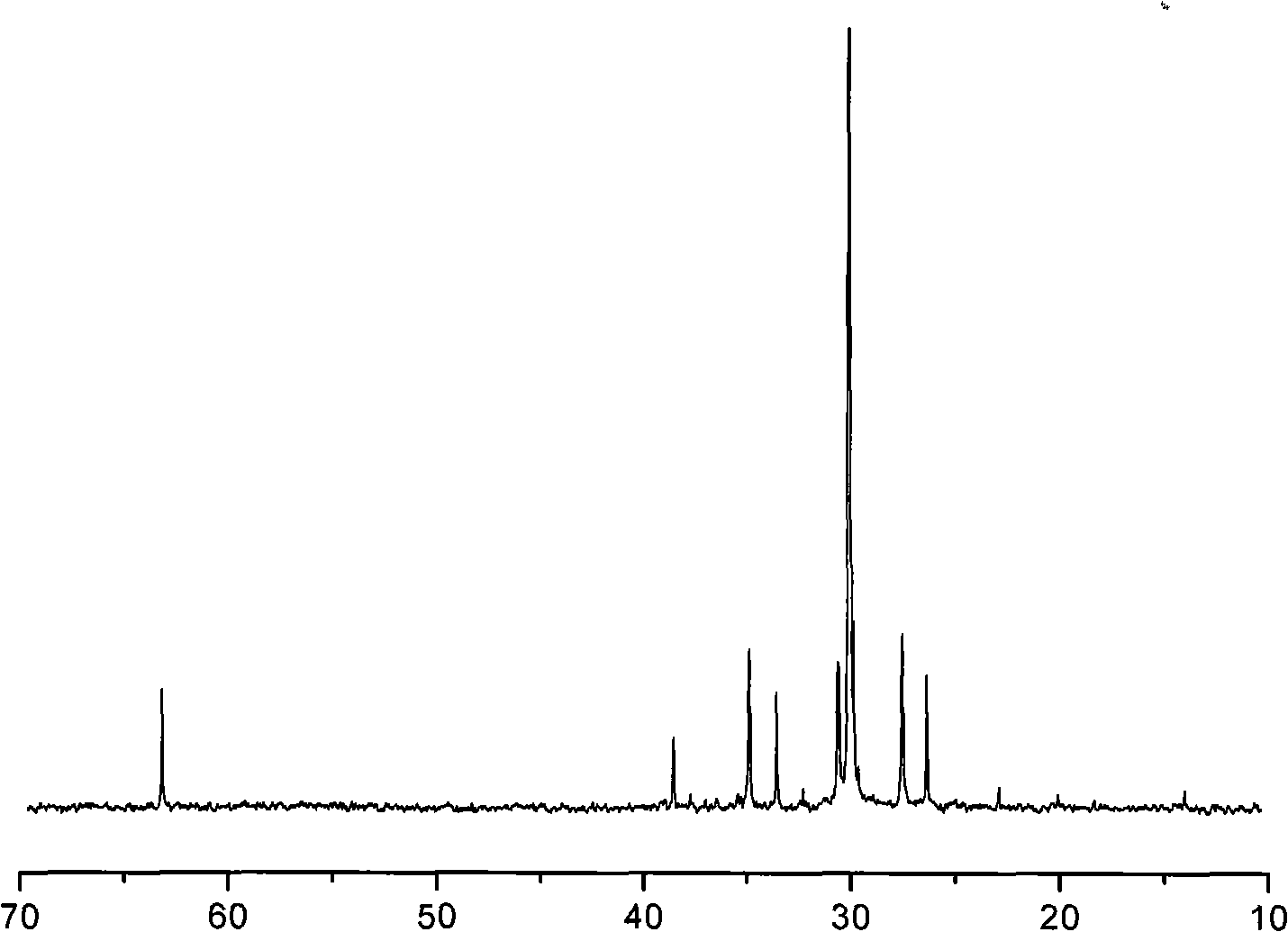

Image

Examples

Embodiment 1

[0026] When embodiment 1 illustrates catalyst catalyzed ethylene / polar α-olefin copolymerization, the copolymerization result of different protecting agent protection 10-undecen-1-alcohols; Hexen-1-ol, Result of copolymerization of ethylene with 3-buten-1-ol, ethylene with 10-undecen-1-ol methyl ester. Example 5 illustrates the polymerization results at different temperatures. Example 6 illustrates the polymerization results after varying the comonomer concentration.

[0027]Embodiment 1a) under a nitrogen atmosphere, under stirring at room temperature, first add anhydrous toluene 50ml and 5M toluene solution 1.0ml of 10-undecen-1-alcohol in a dry 150ml polymerization reactor, then add 2M 2.5 ml of toluene solution of diethylaluminum chloride was used to pretreat 10-undecen-1-ol, and the pretreatment time was 5 minutes. In the above-mentioned pretreated 10-undecen-1-ol reactor, under an ethylene atmosphere, adjust the reaction temperature to 50°C, add 2.0ml of 2M diethylalum...

Embodiment 2

[0062] Under nitrogen atmosphere, under stirring at room temperature, first add 50ml of anhydrous toluene and 1.0ml of 5M 5-hexen-1-ol toluene solution into a dry 150ml polymerization reactor, and then add 2M diethyl chloride 2.5 ml of aluminum toluene solution pretreated 5-hexen-1-ol, and the pretreatment time was 5 minutes. In the above-mentioned pretreated 5-hexen-1-ol reactor, under an ethylene atmosphere, adjust the reaction temperature to 50°C, add 2.0 ml of a toluene solution of 2M diethylaluminum chloride, 0.5M tris 1.0ml of toluene solution of ethyl chloroacetate, and finally 1.0ml of toluene solution of 1.0M bidentate N, O coordinated vanadium olefin polymerization catalyst was added, the ethylene pressure was adjusted to 0.1MPa, and the reaction was polymerized for 10min under stirring. Pour into 0.5% hydrochloric acid ethanol solution by volume, filter, wash with 50ml of ethanol, then wash with 50ml of acetone, and dry in vacuum to obtain a copolymer product. The ...

Embodiment 3

[0075] Under nitrogen atmosphere, under stirring at room temperature, first add 50ml of anhydrous toluene and 1.0ml of 5M toluene solution of 3-buten-1-ol into a dry 150ml polymerization reactor, and then add 2M diethyl chloride 2.5 ml of aluminum toluene solution pretreated 3-buten-1-ol, and the pretreatment time was 5 minutes. In the above-mentioned pretreated 3-buten-1-ol reactor, under an ethylene atmosphere, adjust the reaction temperature to 50° C., add 2.0 ml of a toluene solution of 2M diethylaluminum chloride, 0.5 M tris 1.0ml of toluene solution of ethyl chloroacetate, and finally 1.0ml of toluene solution of 1.0M bidentate N, O coordinated vanadium olefin polymerization catalyst was added, the ethylene pressure was adjusted to 0.1MPa, and the reaction was polymerized for 10min under stirring. Pour into 0.5% hydrochloric acid ethanol solution by volume, filter, wash with 50ml of ethanol, then wash with 50ml of acetone, and dry in vacuum to obtain a copolymer product....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Catalytic activity | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com