A Living Polymerization System Based on Phosphine-Based Catalyzed Synthesis of Ultra-High Molecular Weight Polymers

An ultra-high molecular weight, base-catalyzed technology, applied in the field of polymer synthesis, can solve the problems of large amount of catalyst, harsh reaction conditions, and wide molecular weight distribution of polymers, etc., to achieve wide applicability of substrates, mild reaction conditions, and narrow molecular weight distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

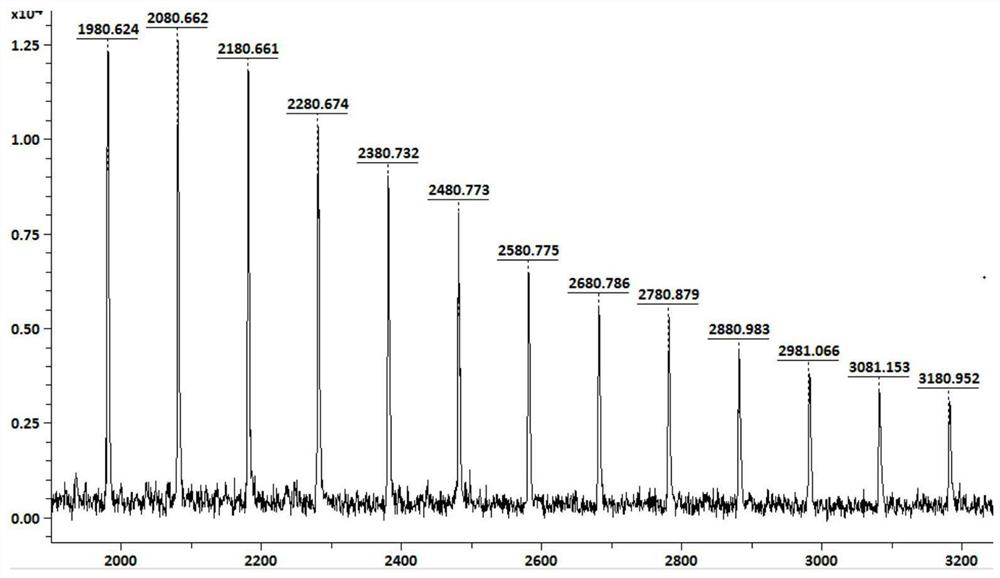

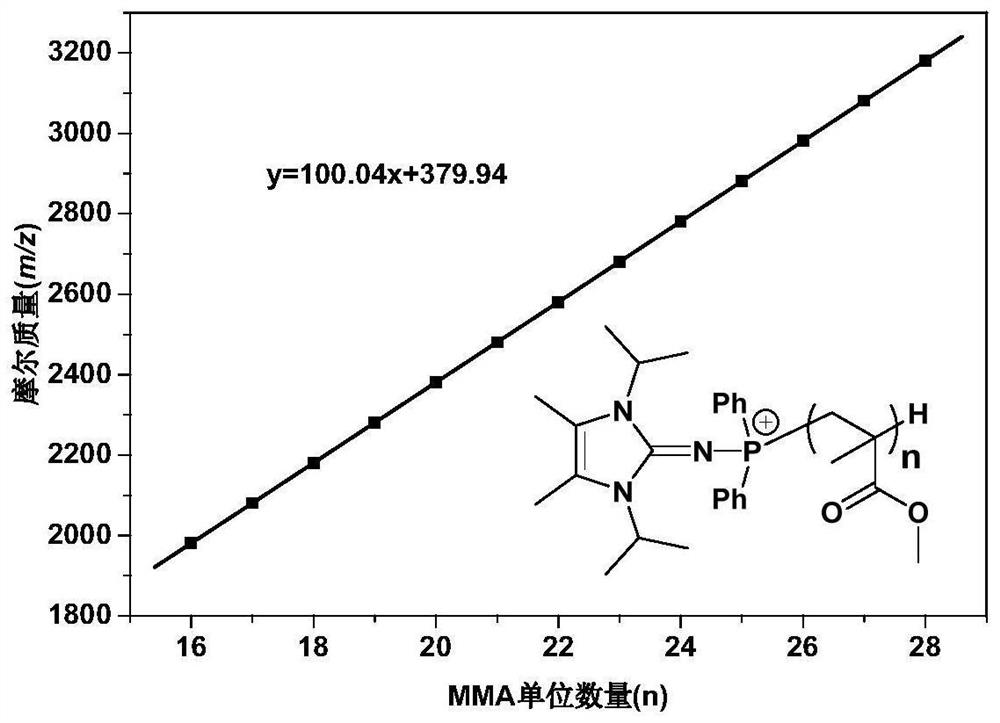

[0040] The conjugate addition polymerization of embodiment 1 methyl methacrylate (MMA)

[0041] There are three feeding methods in the polymerization process: 1. Pre-mix Lewis acid and Lewis base for 10 minutes, and then add monomer; 2. Pre-mix Lewis acid and monomer, and then add Lewis base; 3. Pre-mix Lewis base and monomer, and then Add Lewis acid. Regardless of the feeding method, the polymerization of methyl methacrylate can be well achieved.

[0042] The polymerization reaction was carried out in a glove box, and methyl methacrylate (0.5mL, 4.68mmol) and toluene were measured and placed in a 20ml reaction bottle (the total volume of the solution obtained was 5mL), and Lewis base and Lewis acid were added respectively, and started Timing and stirring for a period of time until the monomers are completely converted, the reaction bottle is taken out of the glove box, and 5% HCl / methanol solution is added to terminate the polymerization reaction. The polymer was filtered o...

Embodiment 2

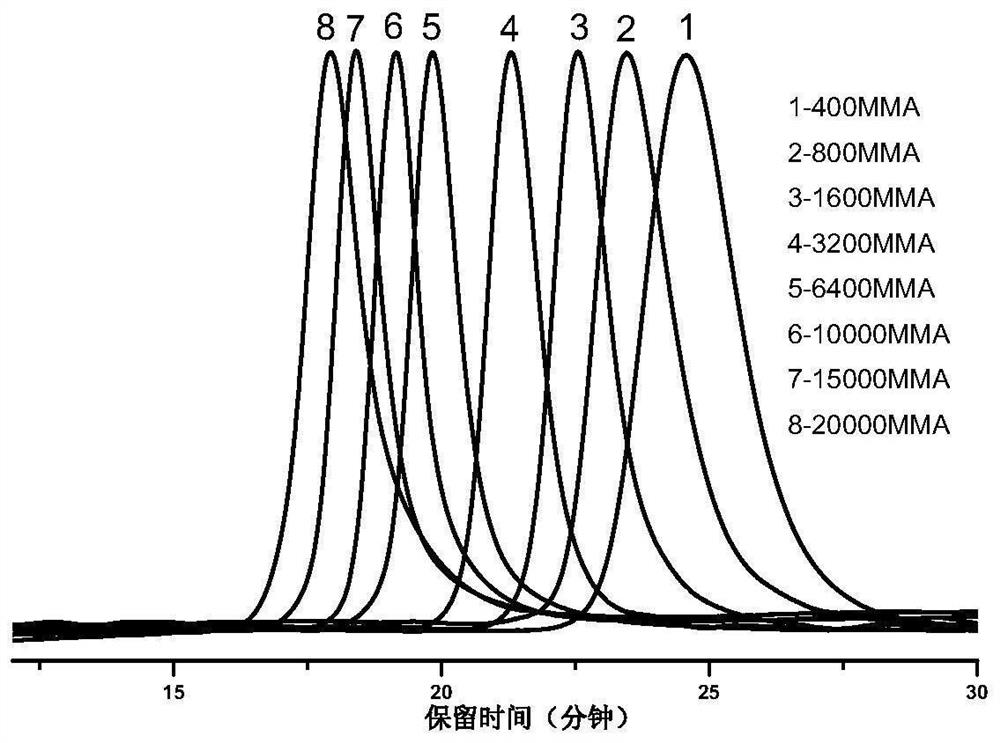

[0047] The chain extension of embodiment 2MMA

[0048] The polymerization reaction was carried out in a glove box, and a certain amount of (BHT)Al was weighed i Bu 2 In the 20 milliliter reaction bottle, add MMA (0.5ml, 4.7mmol), after treating that monomer and Lewis acid fully react, add dichloromethane as solvent (solution total volume is 5mL), add the IAP3 that has weighed, and Start timing, stir until the monomers are completely converted, then add the same amount of MMA (0.5ml, 4.7mmol), repeat this several times, after all the monomers are completely converted, take the reaction bottle out of the glove box, add 5 % HCl / methanol solution to terminate the polymerization. The polymer was filtered off, washed thoroughly with methanol, and dried under vacuum at 50°C to constant weight. The molecular weight and molecular weight distribution of the resulting polymers were determined by gel permeation chromatography.

[0049] Using IAP3 with (BHT)Al i Bu 2 The results of c...

Embodiment 3

[0052] Copolymerization of embodiment 3 methyl methacrylate (MMA) and ethyl methacrylate (EMA)

[0053] Taking the preparation of poly(PMMA-block-PEMA-block-PMMA) as an example: the polymerization reaction is carried out in a glove box, and a certain amount of Lewis acid is weighed in a 20 ml reaction bottle, and MMA (0.5ml, 4.7mmol) is added After the monomer and Lewis acid fully reacted, add tetrahydrofuran as a solvent (the total volume of the solution is 5mL), add the weighed IAP3, and start timing, stir for a period of time, and then add EMA (632 μL , 4.7mmol), after the complete conversion of the monomers, add MMA (0.5ml, 4.7mmol), after the complete conversion of all the monomers, take the reaction bottle out from the glove box, add 5% HCl / methanol solution to terminate the polymerization reaction . The polymer was filtered off, washed thoroughly with methanol, and dried under vacuum at 50°C to constant weight. The molecular weight and molecular weight distribution of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com