Glass fiber reinforced polymer rebar prestressed anti-floating anchor stock and construction method thereof

A glass fiber reinforced, anti-floating anchor technology, applied in the direction of building reinforcements, infrastructure engineering, sheet pile wall, etc. effect, poor lateral shear resistance of fiber reinforcement, etc., to shorten the construction period, avoid uneven force, and control the construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

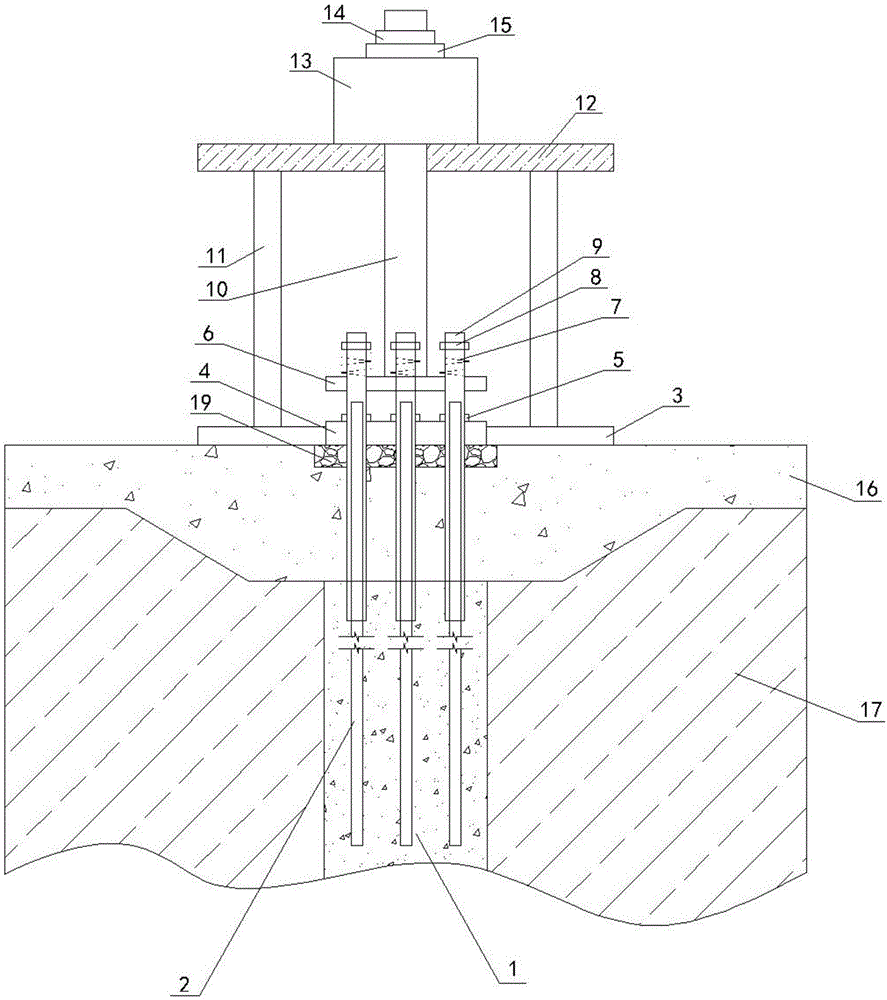

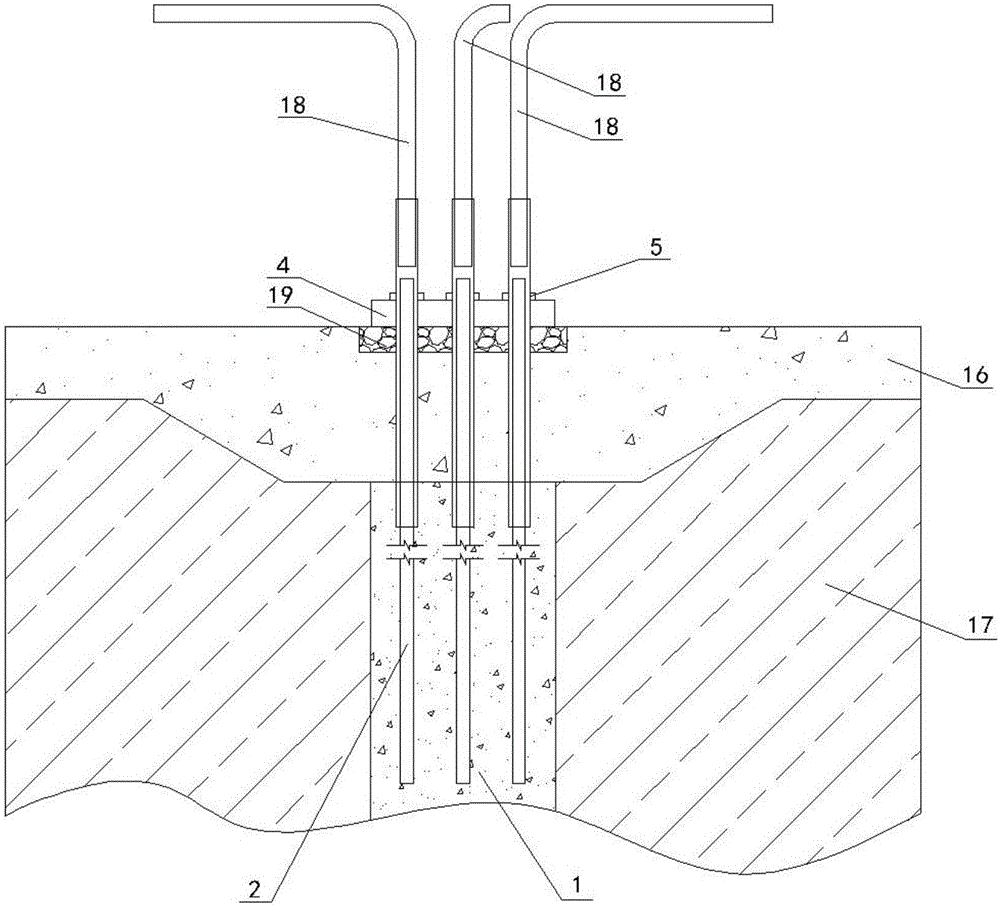

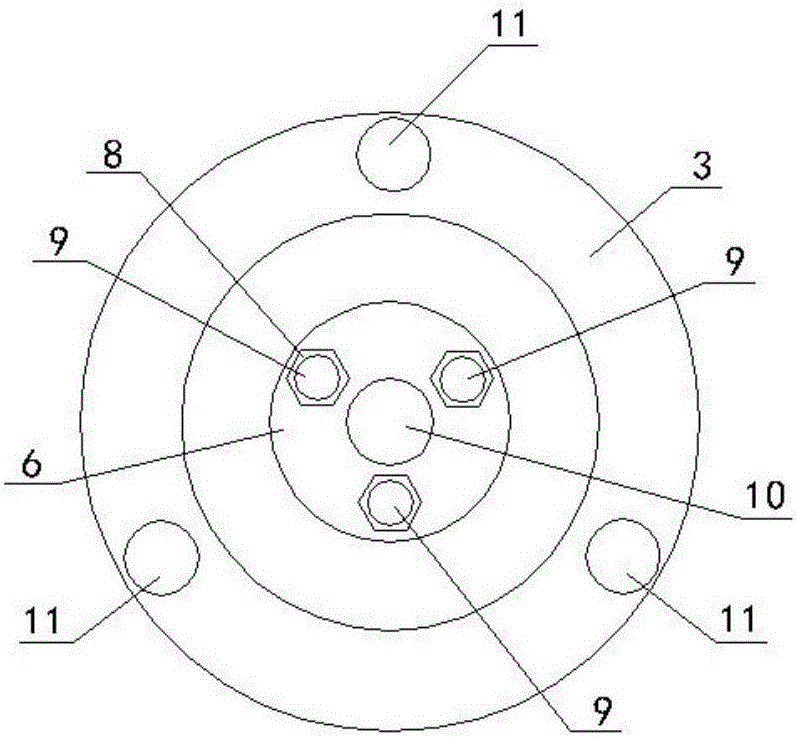

[0033] see figure 1 and figure 2 , the structural form of the glass fiber reinforcement prestressed anti-floating anchor rod loading device in the present embodiment is:

[0034] Set a section of steel casing 9, the bottom pipe end of the steel casing 9 penetrates the floor cushion 16 and goes deep into the rock base 17, the lower section of the anchor rod 2 is anchored in the rock base 17 with mortar 1, and the upper section of the anchor rod 2 is set on the steel In the casing 9, the filled epoxy resin is used to consolidate between the steel casing 9 and the anchor rod 2, and the anchor rod 2 is a GFRP anchor rod.

[0035] The lower bearing plate 4 is placed on the floor cushion 16, and the lower bearing plate 4 utilizes a through hole to slide on the steel casing 9, and on the steel sleeve 9, a lock nut 5 is set above the lower bearing plate 4, and locked The bearing plate 4 below the nut 5 is the locking end face.

[0036] At the bottom of the bearing plate 4 , locate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com