Glass fiber-reinforced polymer concrete pile containing optical fibers

A technology of glass fiber reinforcement and concrete piles, applied in the field of building foundations, to achieve the effects of easy supervision of project quality, low cost, and easy quality control and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

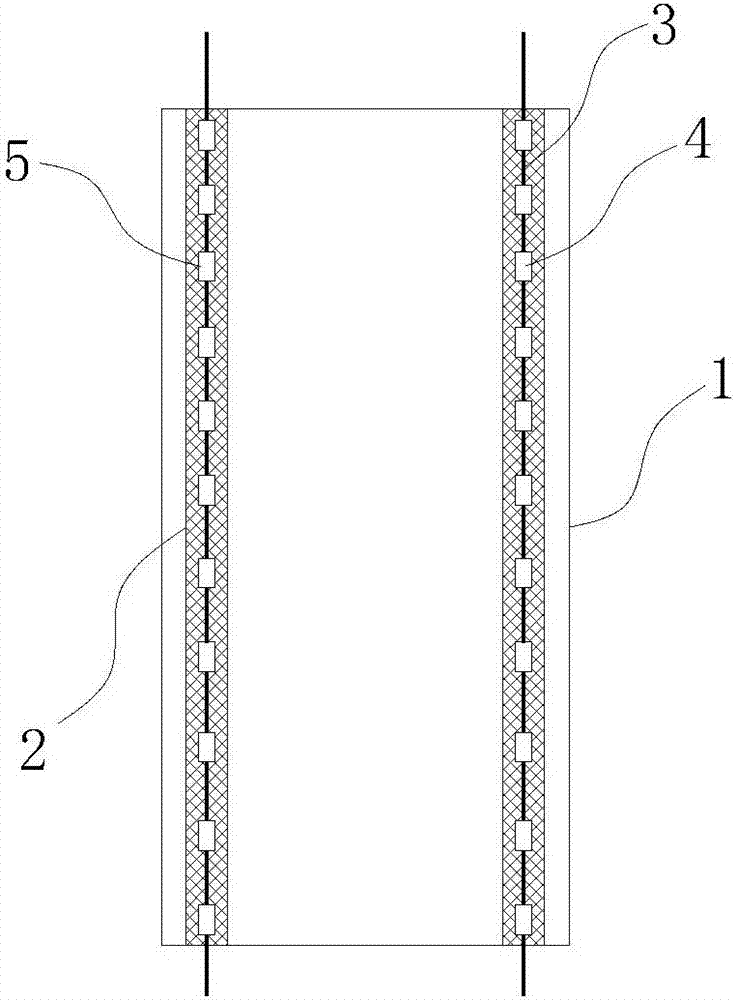

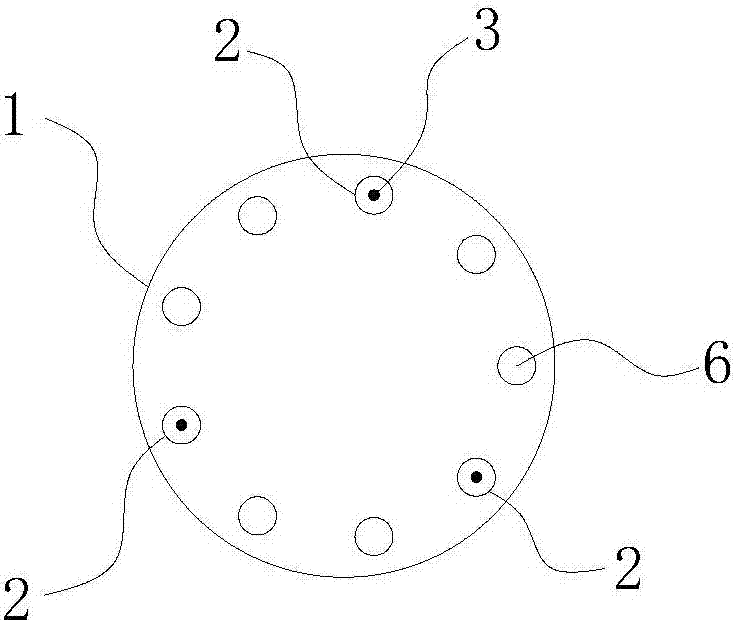

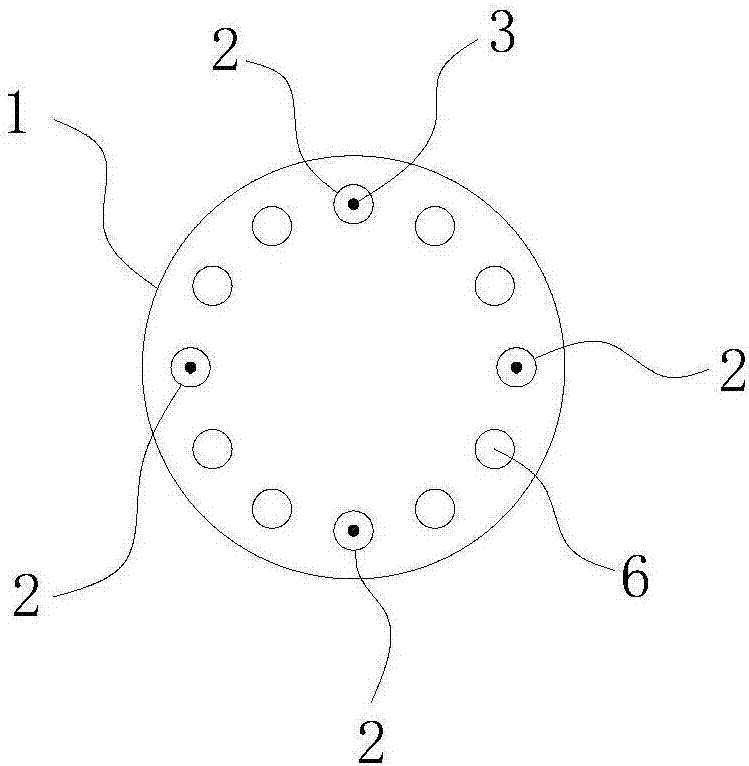

[0025] like figure 1 As shown, a glass fiber-reinforced concrete pile containing optical fibers includes a pile body 1 and a glass fiber reinforcement 2 that is located in the pile body 1 and constitutes the longitudinal main reinforcement of the pile body 1. The glass fiber reinforcement 2 has built-in glass fiber reinforcement 2 An optical fiber 3 arranged in the longitudinal direction and a plurality of strain sensors 4 and / or acoustic wave sensors 5 arranged at intervals along the longitudinal direction of the glass fiber rib 2, the detection signals of the strain sensors 4 and acoustic wave sensors 5 are output through the optical fiber 3.

[0026] The glass fiber reinforcement 2 is bound on the reinforcement cage in the pile body 1, and the end of the optical fiber 3 extends beyond the end of the pile body 1 to connect with the signal acquisition m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com